Waste incineration treatment method

A technology of waste incineration and treatment method, applied in combustion methods, separation methods, chemical instruments and methods, etc., can solve the problems of domestic waste treatment, insufficient incineration, high input and operating costs, and reduce calorific value losses and viruses. The effect of high transmission and combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

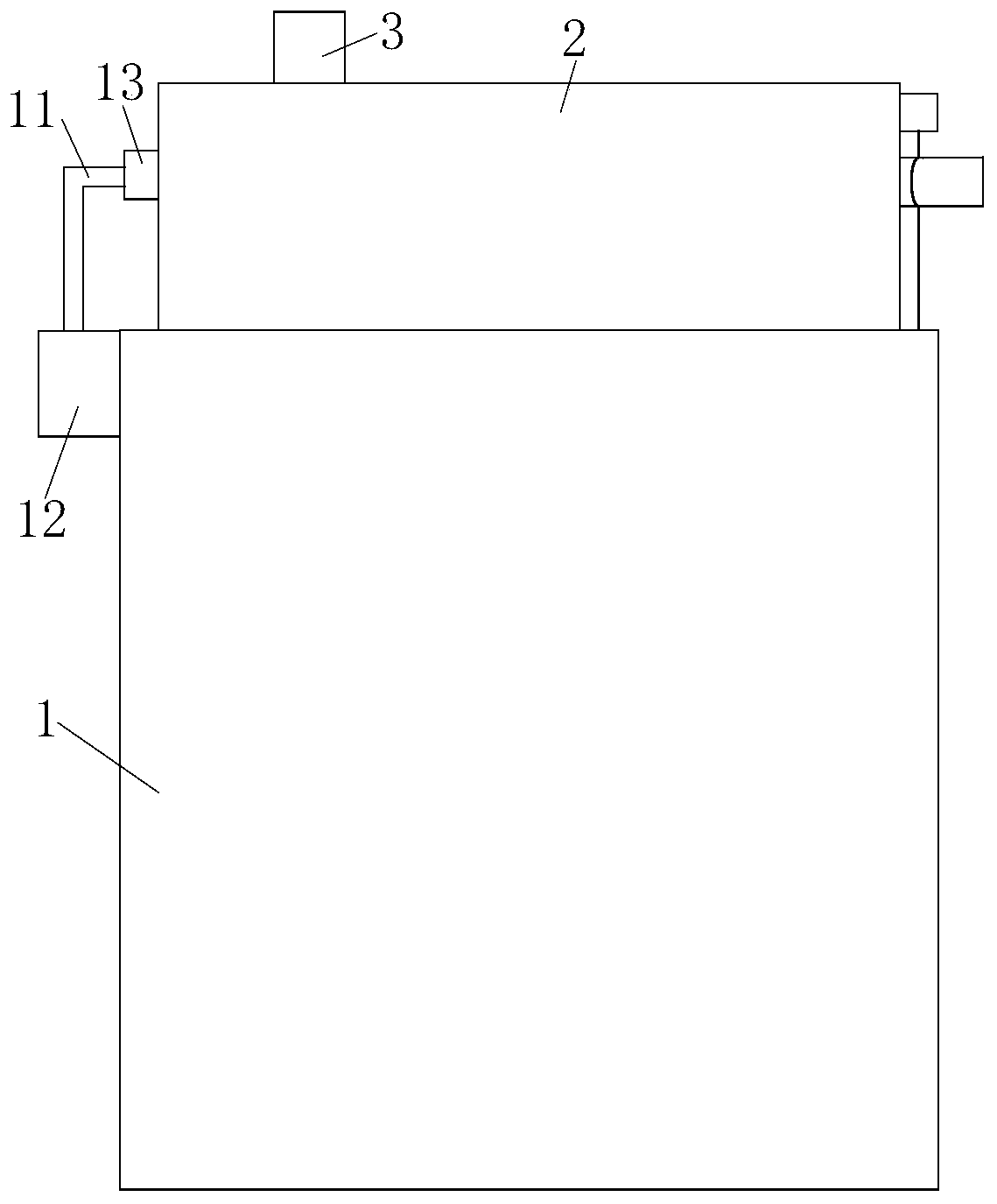

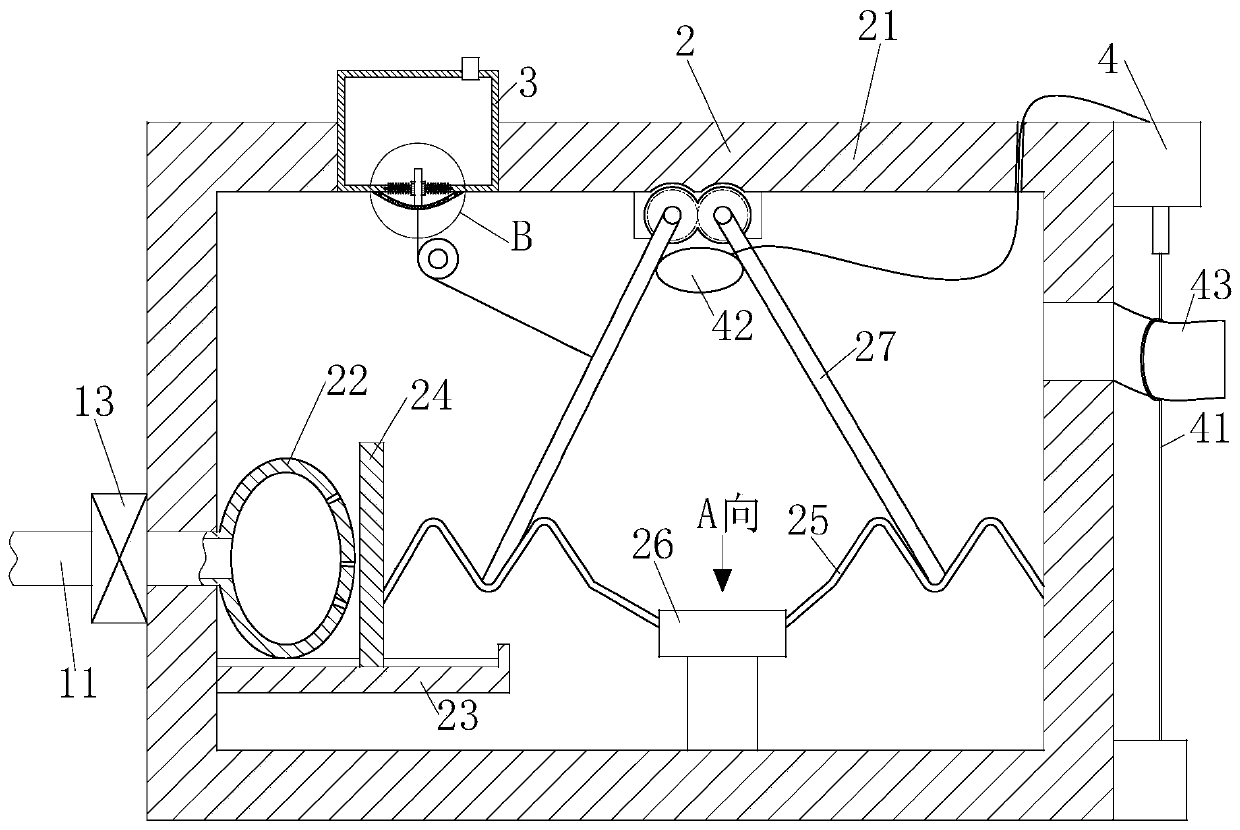

[0029] use Figure 1 to Figure 7 A garbage incineration treatment method of the present invention is described as follows.

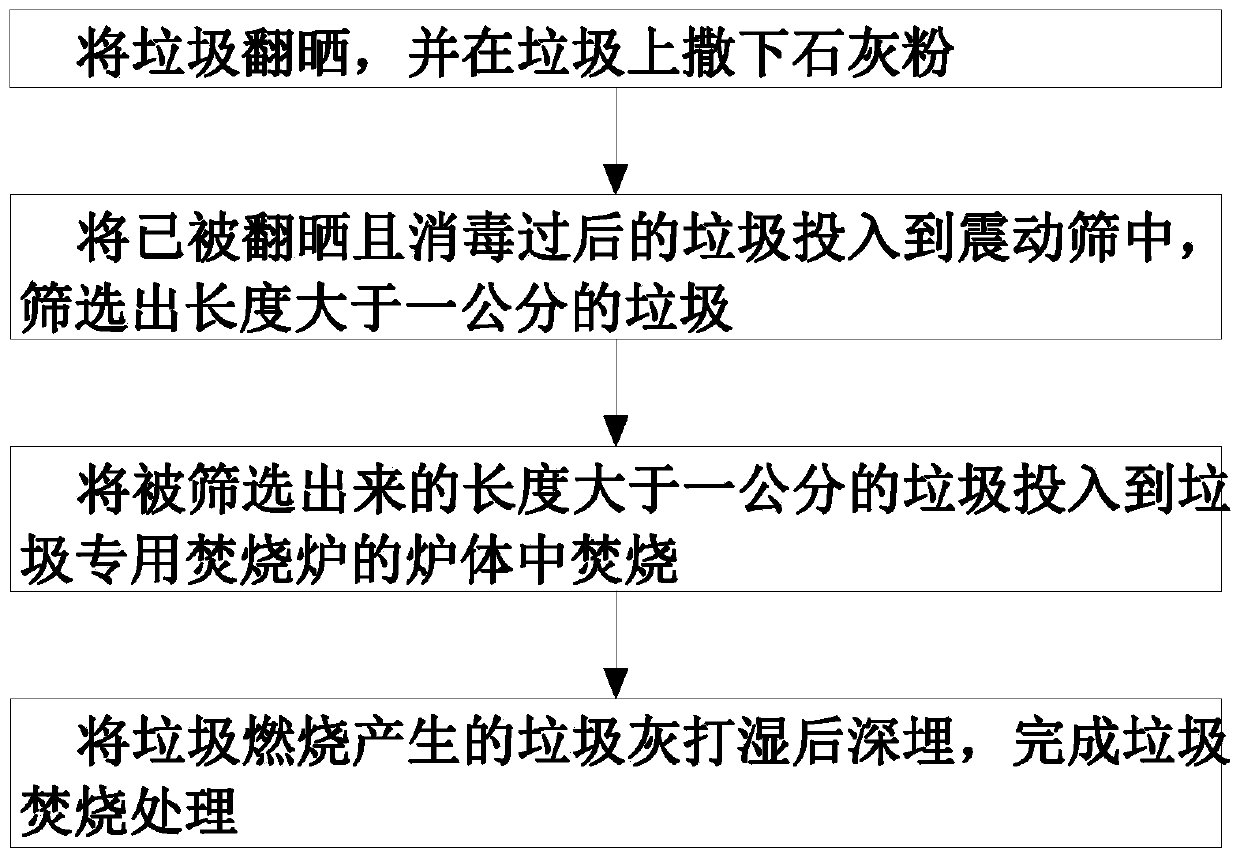

[0030] Such as Figure 1 to Figure 7 Shown, a kind of waste incineration treatment method of the present invention, this method comprises the steps:

[0031] S1, turn the garbage in the sun, and sprinkle lime powder on the garbage; on the one hand, use lime powder to absorb the moisture on the garbage, and on the other hand, use lime powder to disinfect and sterilize the garbage to reduce the spread of viruses in the garbage;

[0032] S2, put the garbage that has been turned and disinfected in S1 into the vibrating sieve, and screen out the garbage with a length of more than one centimeter; divide the garbage into those with a length of more than one centimeter and those with a length of less than one centimeter, because the garbage with a length of less than one centimeter Most of the garbage is dust and sand particles, which are not easy to burn. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com