Full-hydraulic deep well drilling machine

A fully hydraulic and hydraulic technology, applied in rotary drilling rigs, drill pipes, drill pipes, etc., can solve the problems of irreparable time, normal construction, and underground temperature rise, avoiding operation interference and facilitating high power. Integrated intelligent control, the effect of reducing the applied load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

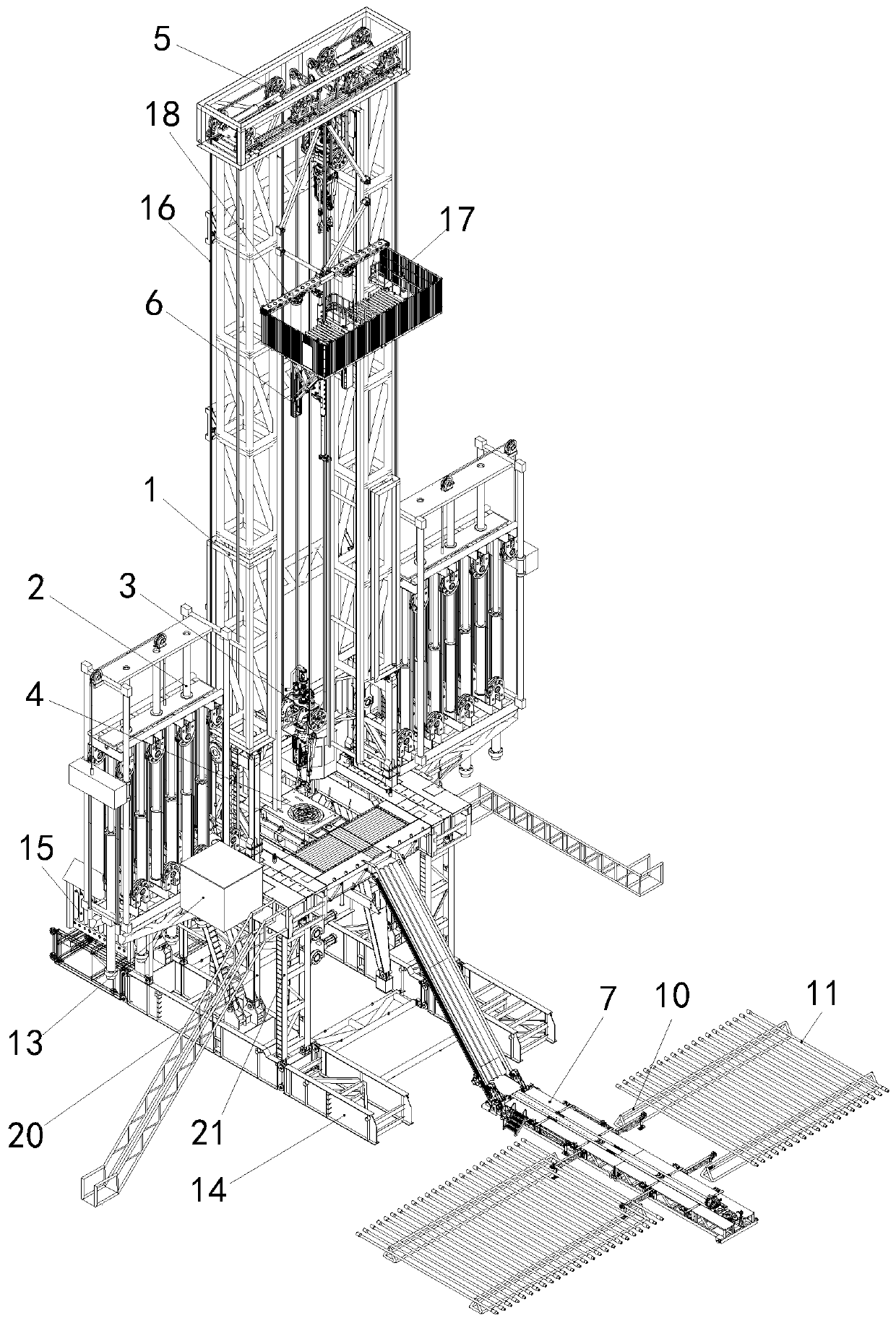

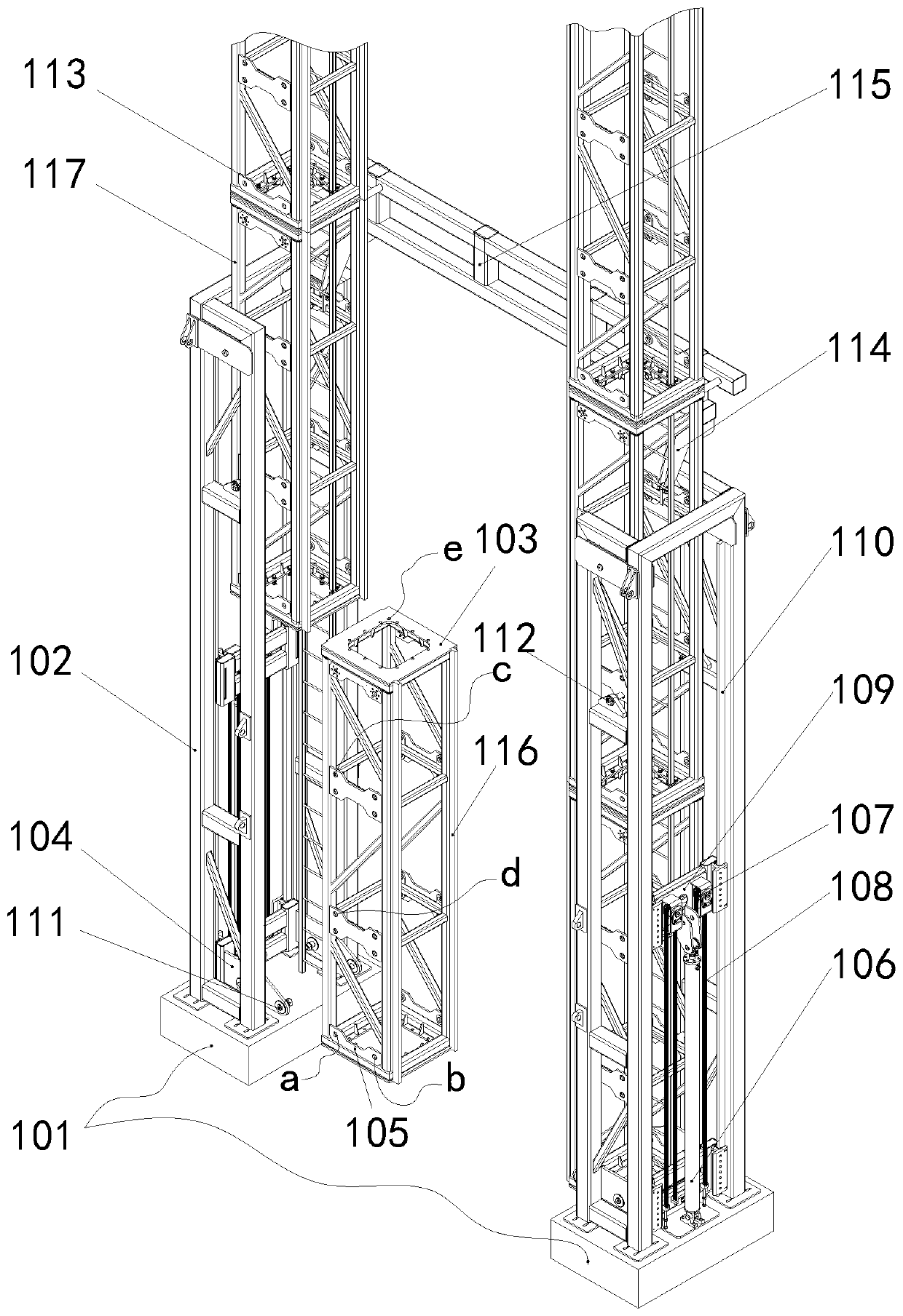

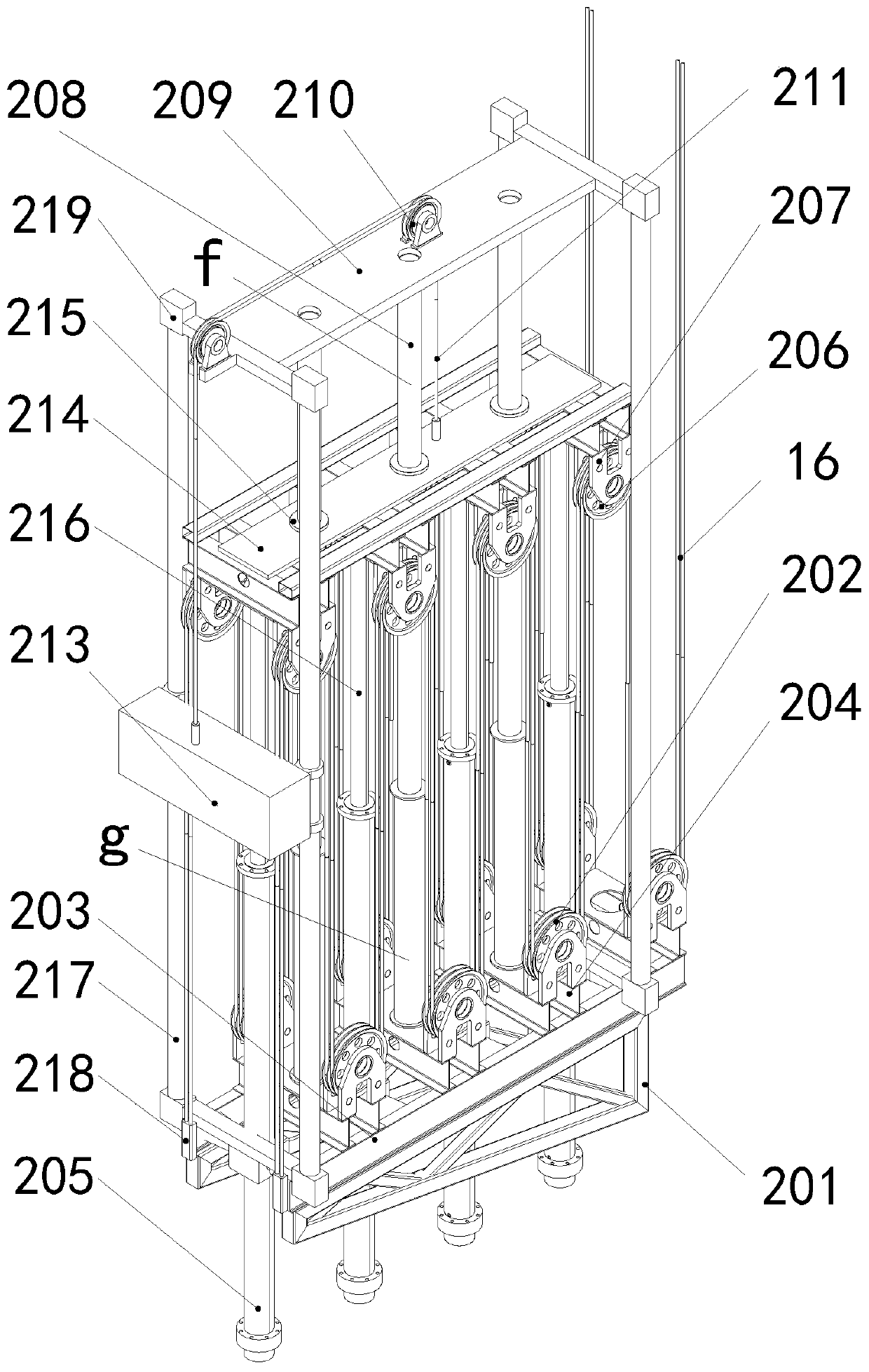

[0047] Such as Figure 1 to Figure 10 As shown, the fully hydraulic deep well drilling rig provided by the present invention includes a drilling tower, a main hydraulic lifting device 2, a hydraulic top drive drilling device 3, a continuous mud circulation device 4, a hydraulic automatic pipe arrangement machine 6, a hydraulic platform drilling tool transportation device 7, Comprehensive hydraulic station 8, drilling rig electrical control system, hydraulic iron driller 12 and reserve hydraulic energy 15, drilling tower, main hydraulic lifting device 2, hydraulic top drive drilling device 3, mud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com