Textile needle seat with adjustable spacing

A textile and spacing technology, applied in textiles and papermaking, deburring devices, fiber processing, etc., can solve the problems of large wear, easy to affect the adjustment and use of needle seats, and inconvenient cleaning, etc., to achieve small wear and improve self-cleaning effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

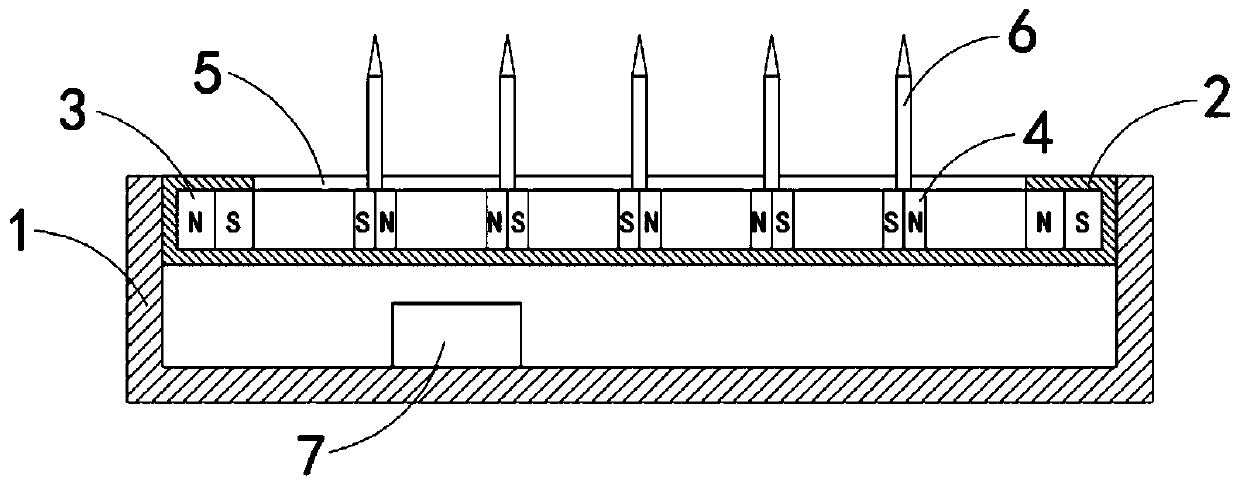

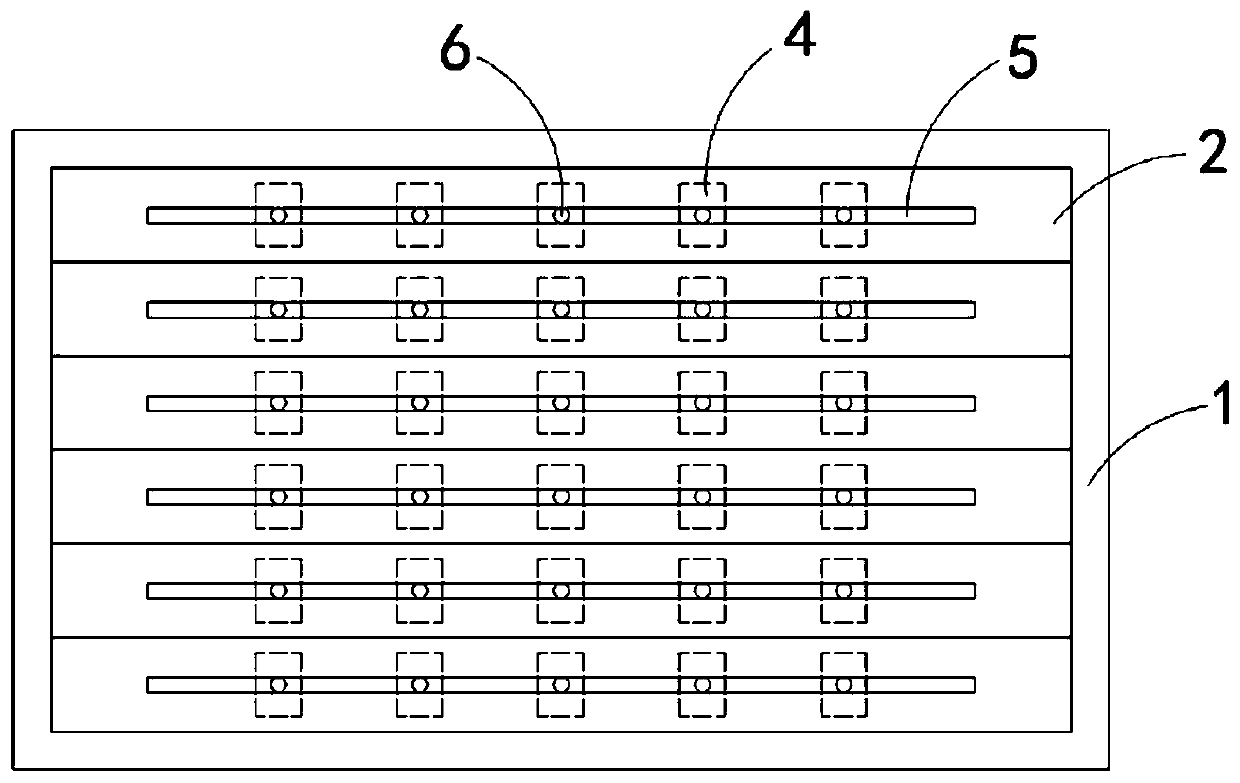

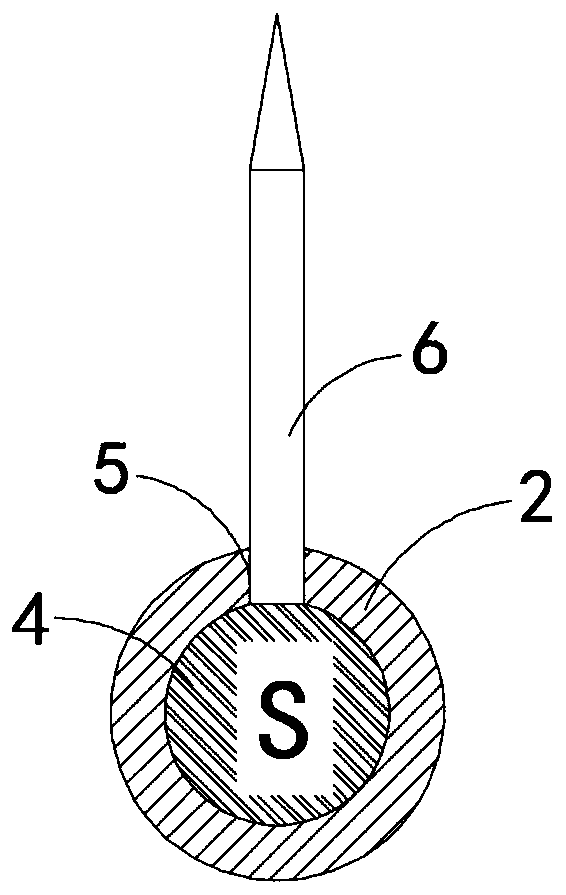

[0026] Such as Figure 1-3 As shown, a textile needle holder with adjustable spacing includes a placement slot 1. In the placement slot 1, a plurality of cylinders 2 arranged side by side and arranged horizontally are fixedly connected. The cylinder 2 is made of a magnetic shielding material to avoid phase differences. There is an influence between the two adjacent cylinders 2. Both ends of the cylinder 2 are fixedly connected with electromagnets 3, and a plurality of permanent magnetic sliders 4 are arranged between the two electromagnets 3. The magnetic induction line of the permanent magnetic slider 4 The direction is parallel to the axial direction of the barrel 2, and the magnetic poles between two adjacent permanent magnetic sliders 4 are opposite. The upper end of the barrel 2 is provided with a strip opening 5, and the upper end of the permanent magnetic slider 4 is fixedly connected with a needle bar 6 , The upper end of the needle bar 6 penetrates through the strip-sha...

Embodiment 2

[0029] Such as Figure 4-6 As shown, the difference between this embodiment and the first embodiment is: a second DC power supply 8 is fixedly installed in the placing slot 1, and the current direction of the second DC power supply 8 is opposite to that of the first DC power supply 7. The power supply 7 and the second DC power supply 8 are coupled with the electromagnet 3 through a pulse switch (such as Image 6 Shown).

[0030] In this embodiment, when the pulse switch is activated, the pulse switch quickly switches back and forth between the first DC power source 7 and the second DC power source 8, so that the magnetic poles of the electromagnet 3 located at both ends of the cylinder 2 are continuously changed, so that The multiple permanent magnetic sliders 4 are continuously separated and gathered together. During the high-frequency switching of the pulse switch, the distance between the adjacent needle bars 6 is continuously changed, causing broken wires or fibers attached be...

Embodiment 3

[0032] Such as Figure 7-8 As shown, the difference between this embodiment and the second embodiment is: an elastic sealing film 9 is fixedly connected between two adjacent permanent magnetic sliders 4, two adjacent permanent magnetic sliders 4, an elastic sealing film 9 and The side walls of the cylinder body 2 jointly form a closed space, the elastic sealing film 9 is provided with a one-way exhaust port 10, and the side wall of the cylinder body 2 is provided with a plurality of one-way air inlets 11, and the side wall of the groove 1 is placed There is a ventilation hole 12 communicating with the outside.

[0033] In this embodiment, when the pulse switch is turned on and the permanent magnet slider 4 moves continuously, the enclosed space becomes larger and smaller, so reciprocating, under the action of the one-way air inlet 11 and the one-way air outlet 10, it can play To the effect of inhalation and blowing, not only can the air below be sucked away, so that the first DC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com