Glass outer protective film for cold environments

A protective sticker and environmental technology, applied in the direction of film/flaky adhesives, surface pretreatment bonding methods, adhesives, etc., can solve problems such as glass breakage, glass stress deformation, glass bursting, etc., to reduce internal and external Temperature difference, reduce the effect of external stress increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

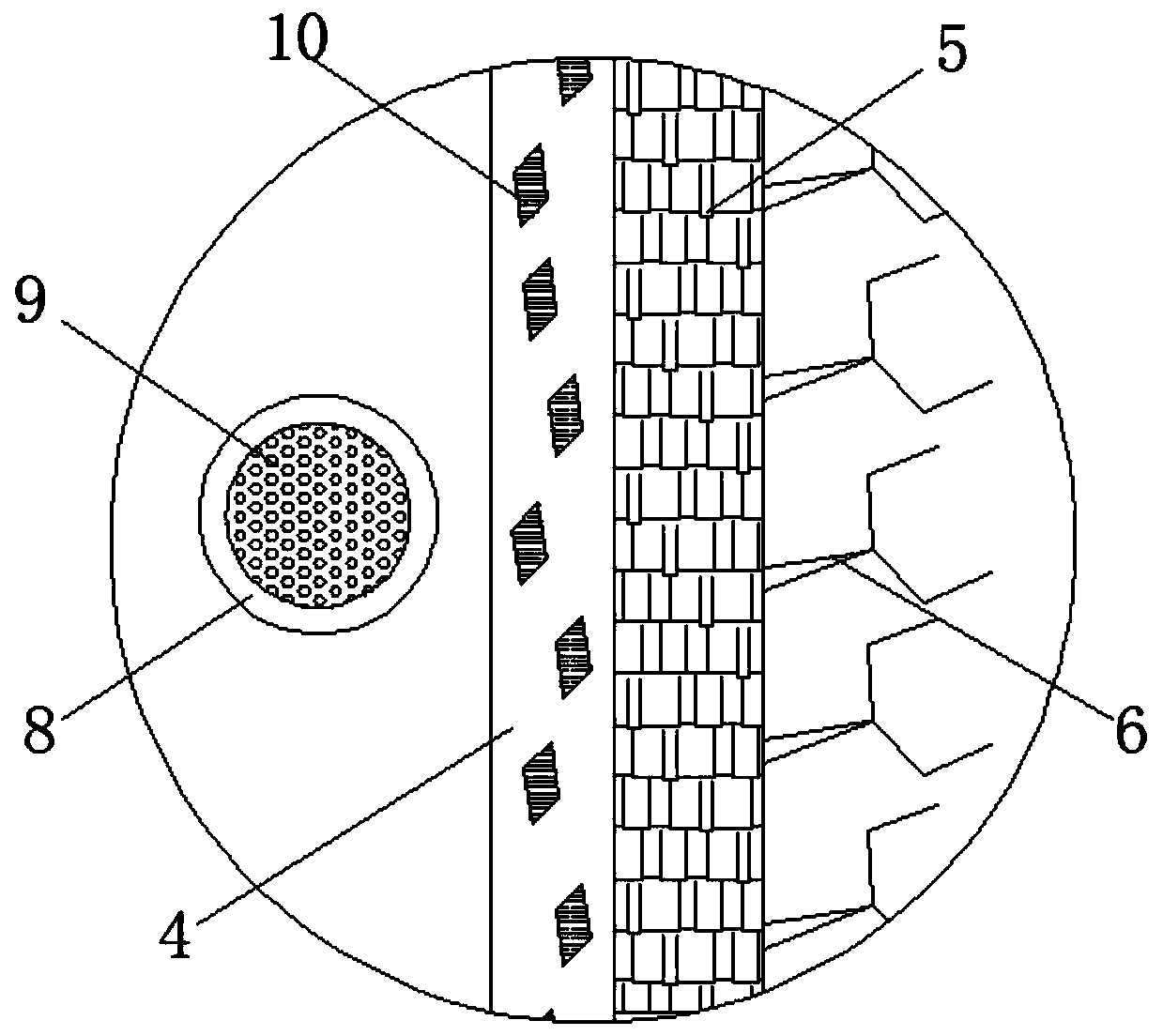

[0043] see Figure 1-3 , a glass outer layer protective film for cold environments, comprising a film adhesive layer 1, an elastic reset interlayer 3 is arranged on the right side of the film adhesive layer 1, and the film adhesive layer 1 and the elastic reset interlayer 3 are fixedly connected There is an inner layer shaped elastic film 2, and the film adhesive layer 1 is fixedly connected with the elastic reset interlayer 3 through the inner layer shaped elastic film 2, and the middle of the elastic reset interlayer 3 is fixedly connected with a flexible memory alloy belt 11, and the right end of the elastic reset interlayer 3 is fixedly connected There is a light-guiding soft polymer layer 4, the right end of the light-guiding soft polymer layer 4 is fixedly connected with a heat-insulating and uniform temperature film 5, the left side of the film adhesive layer 1 is provided with a glass substrate body 7, and the left end of the film adhesive layer 1 is connected to the T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com