Graphene high-performance stone-like paint and preparation method thereof

A graphene and high-performance technology, which is applied in the field of graphene high-performance real stone paint and its preparation, can solve the problems that affect the decorative effect and service life of real stone paint, poor water resistance, alkali resistance and aging resistance, and large porosity of the paint film. , to achieve the effects of inhibiting the growth of algae, excellent alkali resistance, and excellent stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

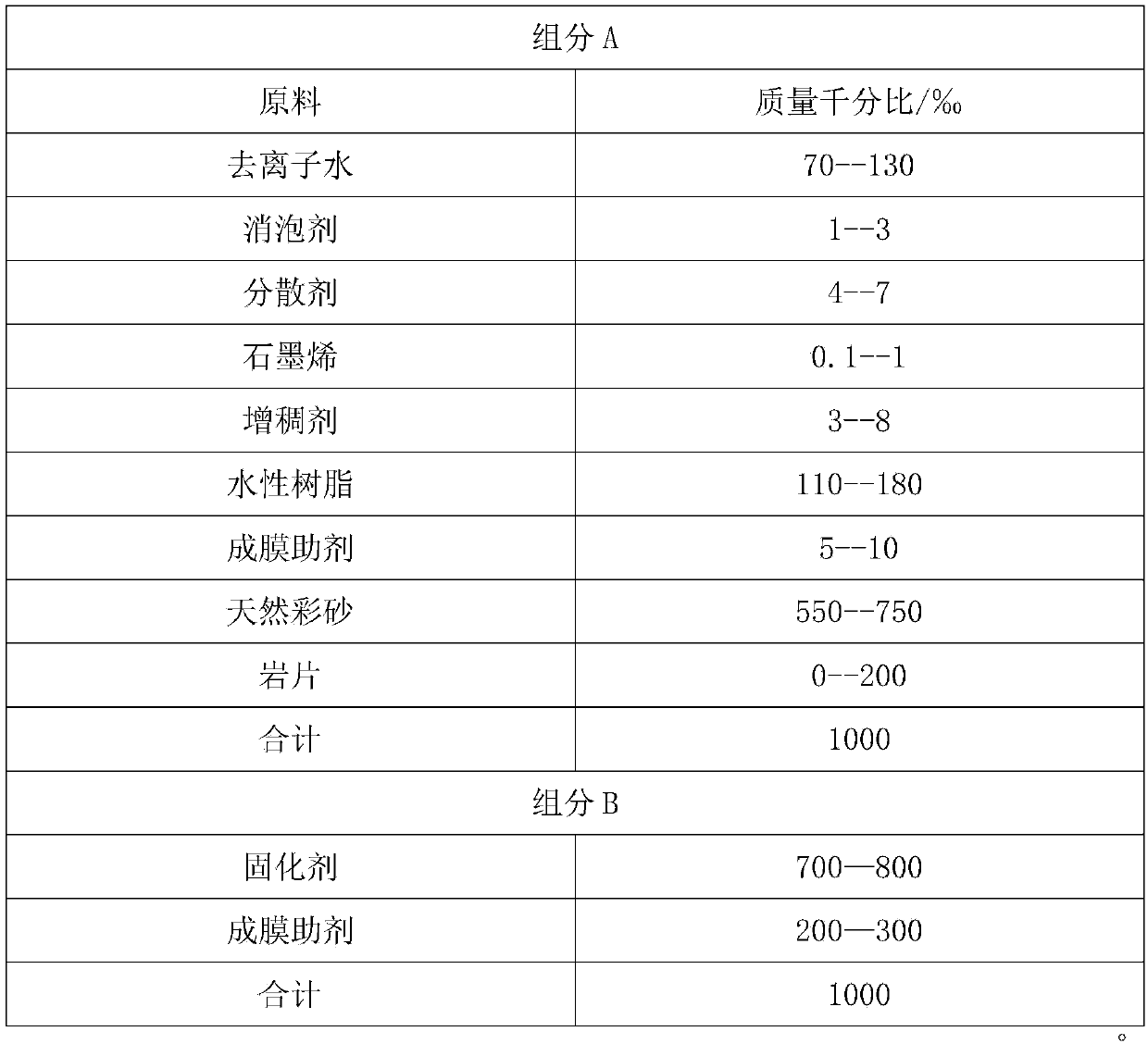

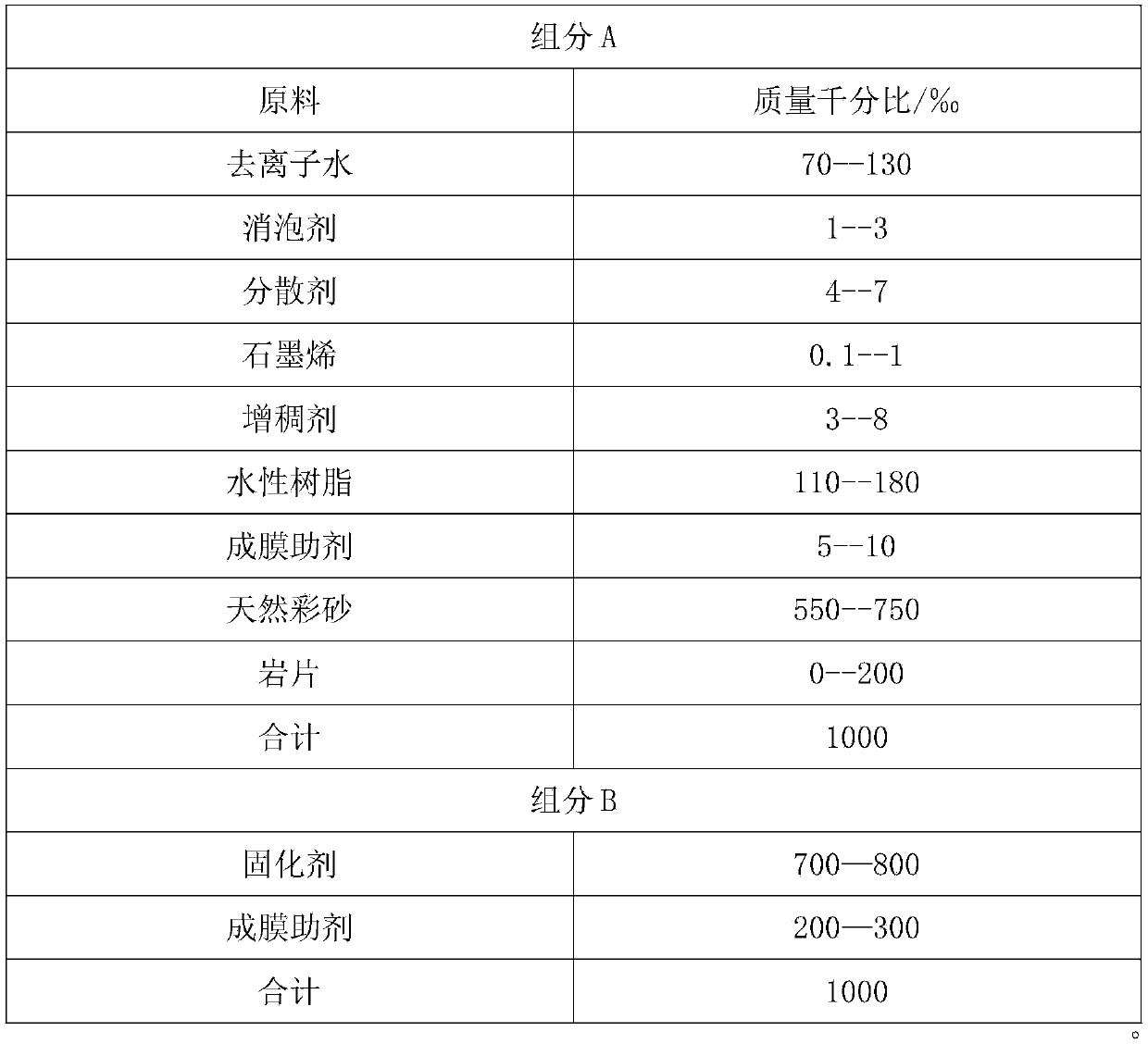

[0026] A kind of graphene high-performance genuine stone paint, is made up of component A and component B, and its mass percent per thousand is as follows:

[0027] ,

[0028] Its preparation method comprises the following steps:

[0029] (1) Add 70.0Kg of deionized water into the dispersing tank, add 3.0Kg of defoamer, 4.0Kg of dispersant, 5.0Kg of 2wt% graphene water-based slurry in turn under low-speed stirring, and the rotating speed is 1000--1500rpm, disperse The time is 20min; then reduce the speed, add 161.9Kg of water-based fluorocarbon resin, 5.0Kg of dodecyl alcohol ester film-forming aid and 6.0Kg of non-ionic associative polyurethane thickener, the speed is 600--800rpm, after stirring evenly Add 480.0Kg of 40--80 mesh chrysanthemum yellow natural colored sand, 80--120 mesh snowflake white 150Kg, and 80--120 mesh chrysanthemum yellow natural colored sand 120.0Kg into the dispersion tank at a speed of 400--600rpm. The time is 5--8min, and the A component is obtai...

Embodiment 2

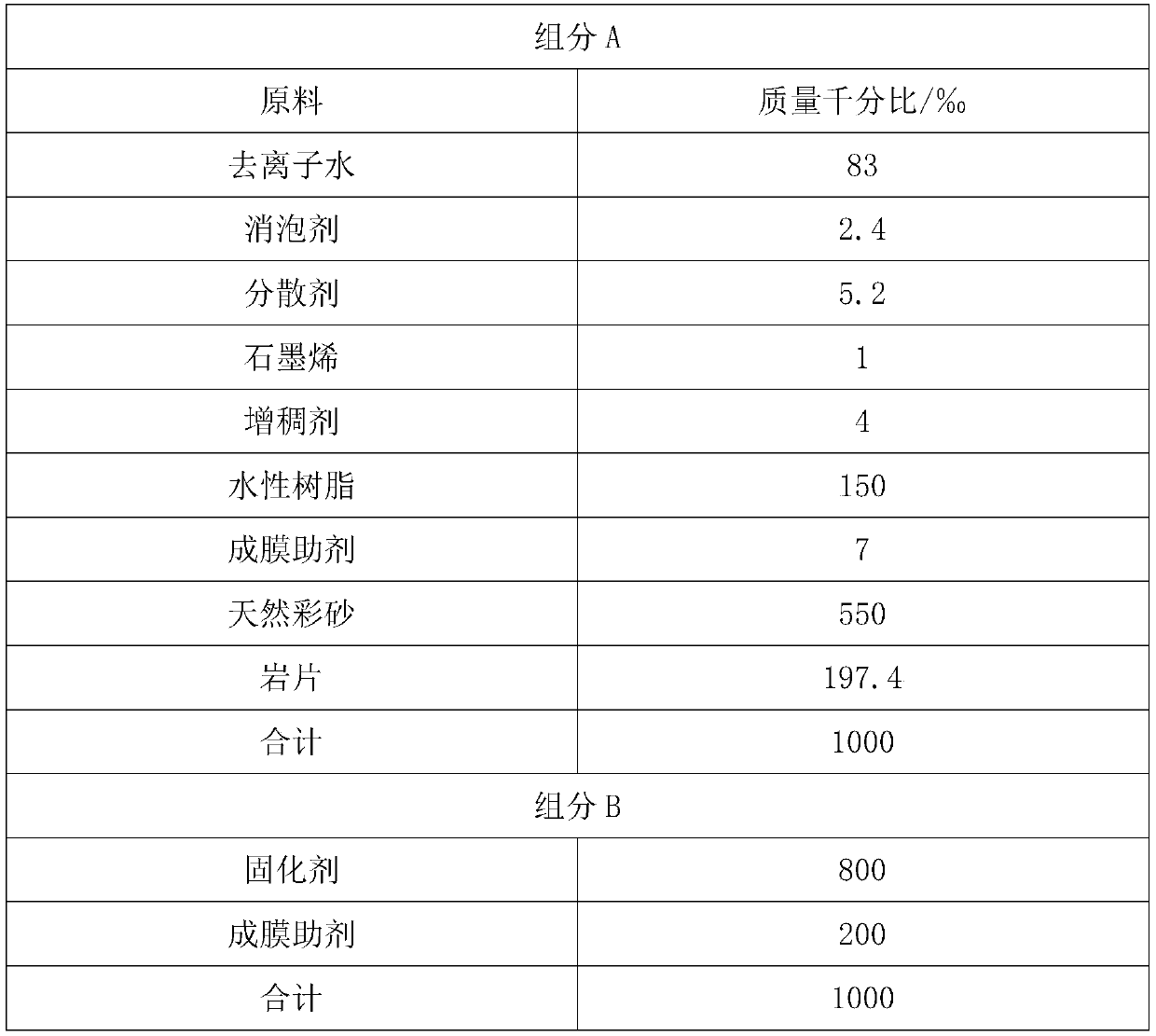

[0033] A kind of graphene high-performance genuine stone paint, is made up of component A and component B, and its mass percent per thousand is as follows:

[0034]

[0035] Its preparation method comprises the following steps:

[0036] (1) Add 83.0Kg of deionized water into the dispersing tank, and add 2.4Kg of defoamer, 5.2Kg of dispersant, and 1.0Kg of nano-mica powder composite graphene powder in turn under low-speed stirring, at a speed of 1000--1500rpm. The time is 20min; then reduce the speed, add 150.0Kg of water-based hydroxyacrylic acid dispersion, 7.0Kg of propylene glycol butyl ether, 0.4Kg of fumed silica thickener and 3.6Kg of polyamide wax thickener, the speed is 600--800rpm, stir After uniformity, 40--80 mesh snowflake white 320.0Kg, 80--120 mesh Chinese red natural colored sand 120.0Kg, 120-180 mesh Chinese red natural colored sand 110Kg, 1--3mm black gold natural rock slice 100.0Kg and 3 -- 97.4Kg of 5mm pure prairie green natural rock slices were added t...

Embodiment 3

[0040] A kind of graphene high-performance genuine stone paint, is made up of component A and component B, and its mass percent per thousand is as follows:

[0041] ,

[0042] Its preparation method comprises the following steps:

[0043](1) Add 108.0Kg of deionized water into the dispersing cylinder, add 1.9Kg of defoamer, 7.0Kg of dispersant, and 0.5Kg of pure graphene powder in sequence under low-speed stirring, with the speed of 1000--1500rpm and the dispersion time of 20min ; Reduce the speed, add water-based polyurethane / acrylic acid composite dispersion 130.0Kg, dipropylene glycol methyl ether acetate 9.0Kg, propylene glycol 1Kg and bentonite thickener 3.0Kg, the speed is 600--800rpm, after stirring evenly, mix 10--20 Baogong black natural colored sand 60.0Kg, 20--40 mesh tiger skin yellow natural colored sand 90.0Kg, 40--80 mesh white marble natural colored sand 400.0Kg, 80--120 mesh white marble natural colored sand 100.0Kg, 1--3mm Add 30.0Kg of black gold natural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com