Graphene and preparation method thereof as well as electrode material

An electrode material, graphene technology, applied in the directions of graphene, hybrid capacitor electrodes, nano-carbon, etc., can solve the problem of low nitrogen doping rate, achieve high doping amount, facilitate adsorption and mass transfer, and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Take 1g of o-phenanthroline hydrochloride, add 20g of deionized water and 20g of ethanol, mix it with a water bath at 60°C, and dissolve it with magnetic stirring; then add 15g of melamine, continue stirring for 4h, then transfer to a blast drying oven, and dry at 100°C 12h, grinding to obtain carbon and nitrogen-containing organic matter.

[0052] The organic matter obtained above was placed in a corundum boat, and carbonized in a tube furnace at 900° C. for 2 h under an argon atmosphere to obtain nitrogen-doped wrinkled graphene with a high specific surface area.

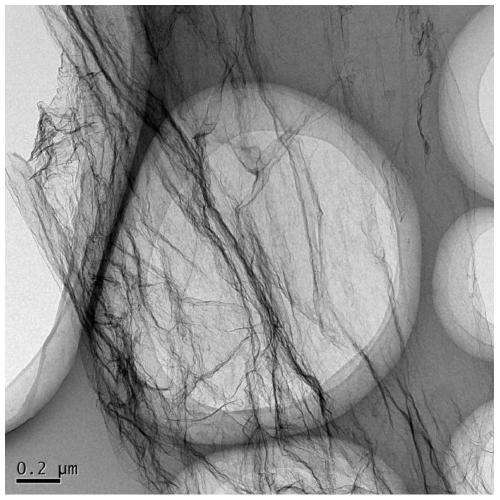

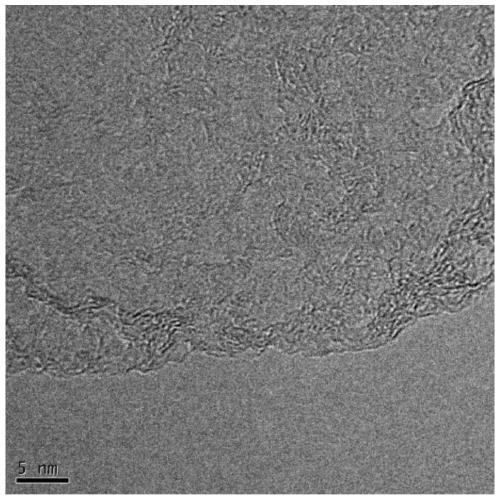

[0053] Graphene prepared by the embodiment of the present invention 1 is carried out transmission electron microscope detection, detection result is as follows figure 1 and figure 2 shown by figure 1 and figure 2 It can be seen that the graphene sheet prepared in Example 1 of the present invention is very thin, and the number of layers is less than 5 layers.

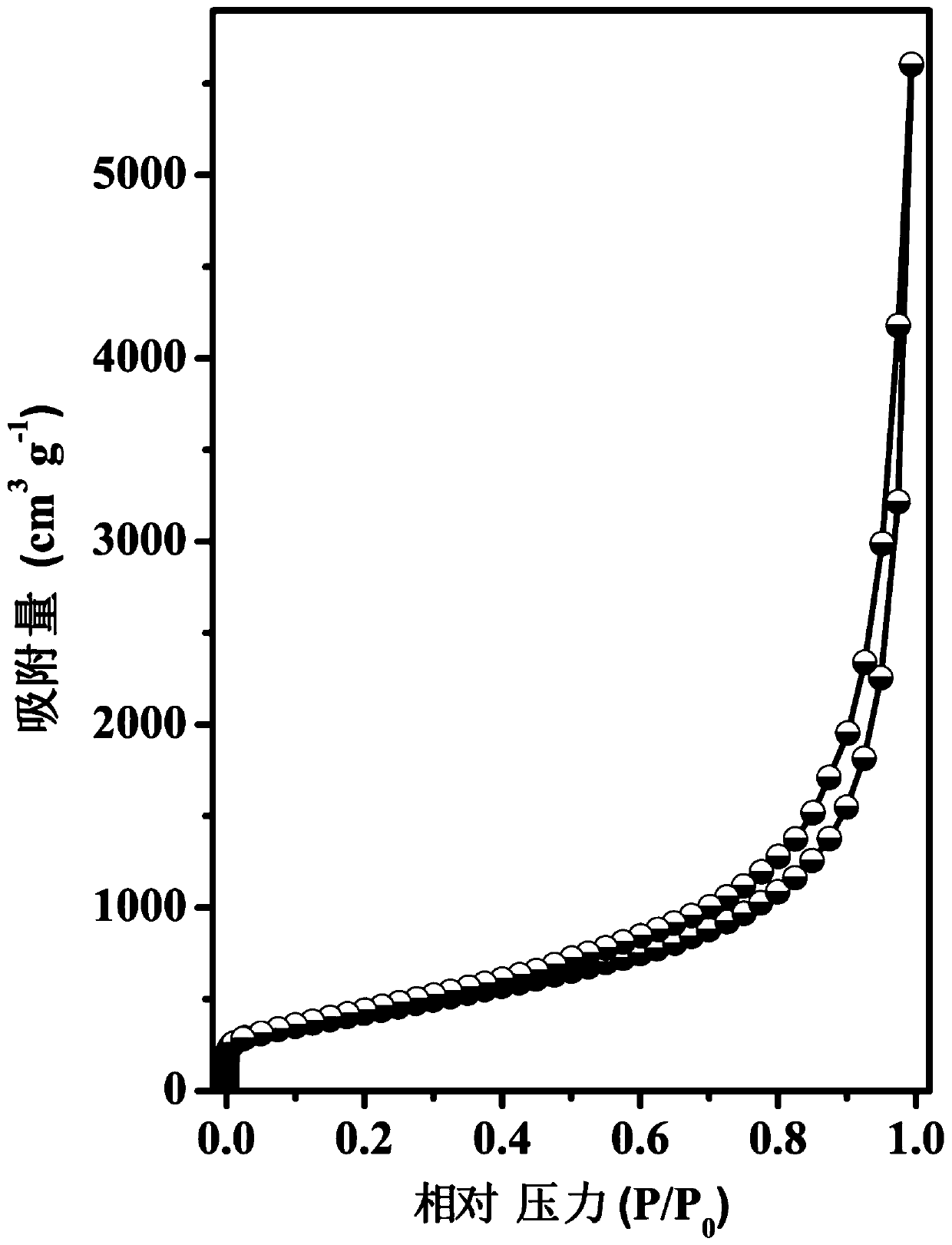

[0054] Adopt Micromeritics ASAP-2020M phy...

Embodiment 2

[0057] Mix 2g of 1,10-phenanthroline with 10g of melamine, and grind until uniform in an agate mortar to obtain carbon and nitrogen-containing organic matter.

[0058] The organic matter obtained above was placed in a corundum boat, and carbonized in a tube furnace at 1000° C. for 4 hours in a nitrogen atmosphere to obtain nitrogen-doped wrinkled graphene with a high specific surface area.

[0059] According to the detection method of embodiment 1, the graphene prepared by the embodiment of the present invention 2 is detected, and the detection result is that the graphene sheet prepared by the embodiment of the present invention 2 is very thin, and the number of layers is below 5 layers; The specific surface area of graphene is 1320m 2 g -1 , with a pore volume of 5.6 cm 3 g -1 ; The graphene prepared by Example 2 of the present invention contains three elements of C, N, and O, and the N content is 11.2 at%.

Embodiment 3

[0061] Take 1.5g of 5,6-dimethyl-1,10-phenanthroline and add it to 50g of methanol, and stir it magnetically in a water bath at 60°C; then add 10g of melamine and continue stirring until the solvent evaporates, then transfer to a blast drying oven , dried at 80°C for 12 hours, and ground to obtain organic matter containing carbon and nitrogen.

[0062] The organic matter prepared above was placed in a corundum boat, and carbonized in a tube furnace at 900°C for 2 hours under an argon atmosphere to obtain nitrogen-doped wrinkled graphene with a high specific surface area.

[0063] According to the detection method of embodiment 1, the graphene prepared by the embodiment of the present invention 3 is detected, and the detection result is that the graphene sheet prepared by the embodiment of the present invention 3 is very thin, and the number of layers is below 7 layers; The specific surface area of graphene is 1288m 2 g -1 , with a pore volume of 5.2 cm 3 g -1 ; The graph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com