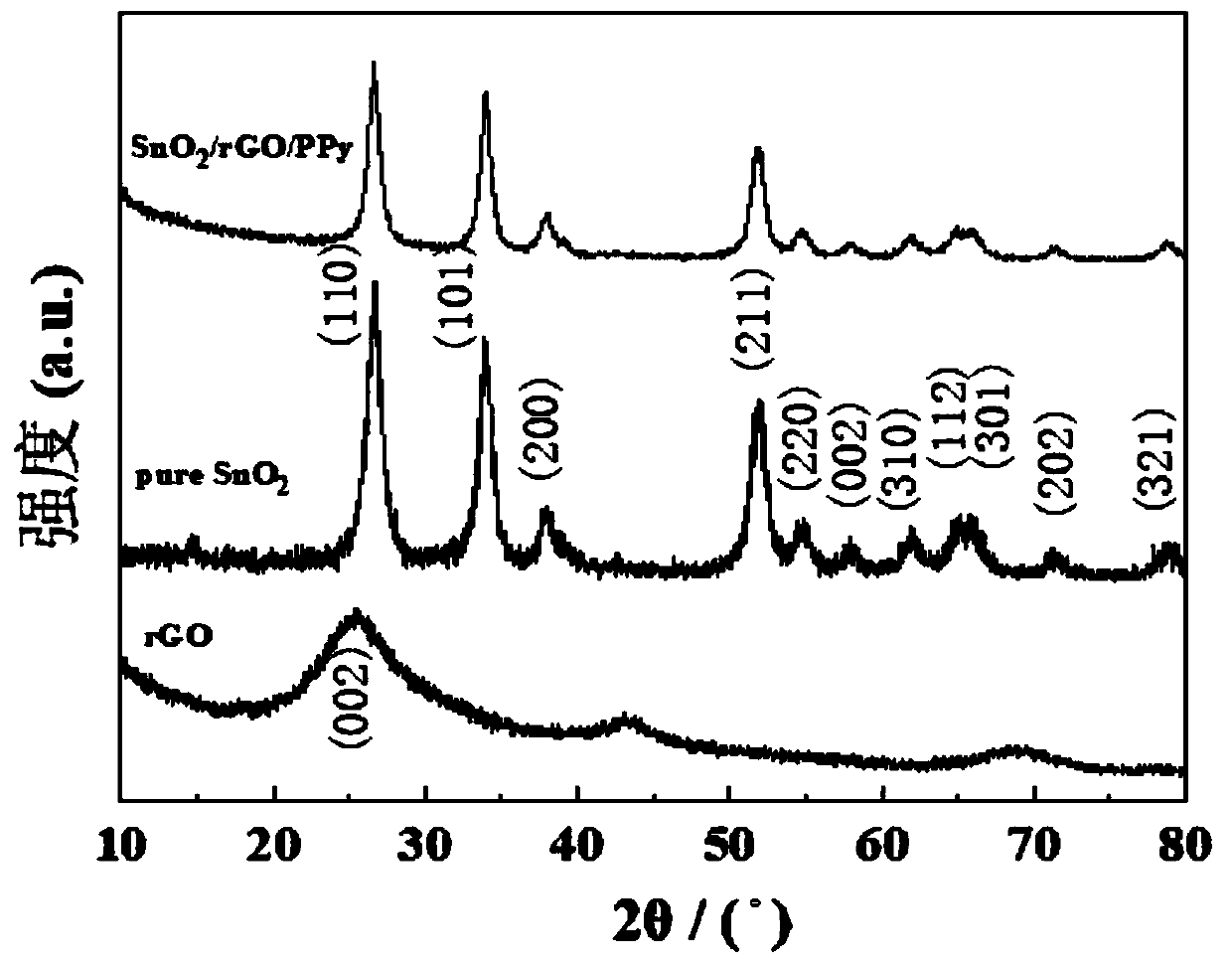

Preparation method of SnO2/graphene/PPy ternary composite material

A composite material and graphene technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of poor cycle performance and rate performance, complicated preparation methods, low efficiency, etc., achieve high capacity and simple synthesis process , Improve the effect of transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In the first step, the graphene material is synthesized by a redox method. In a 250mL three-neck flask equipped with a mechanical stirrer, add 150mL of concentrated sulfuric acid, and cool down to 0°C in an ice bath. To the above concentrated sulfuric acid, add 6.5g of graphite powder. Under stirring, in the three-necked flask, add 19.5g KMnO in batches 4 , the reaction temperature does not exceed 20°C. KMnO 4 After the addition was complete, stirring was continued for 40 min under an ice bath. Then, the reaction was continued at 35° C. for 2 h, and the above reaction solution was poured into 460 mL of distilled water, and stirred at 60° C. for 1 h. Then, the reaction solution was poured into a mixed solution of 1.4 L of water and 100 mL of hydrogen peroxide, and stirred for 24 h. Filter, wash three times with 5% hydrochloric acid solution, and dry at 70°C for 72 hours to obtain graphite oxide. Graphene is obtained by sintering graphite oxide at 800°C for 60s;

...

Embodiment 2

[0022] The 1st step, the step of synthesizing graphene material with redox method is identical with the 1st step in embodiment 1;

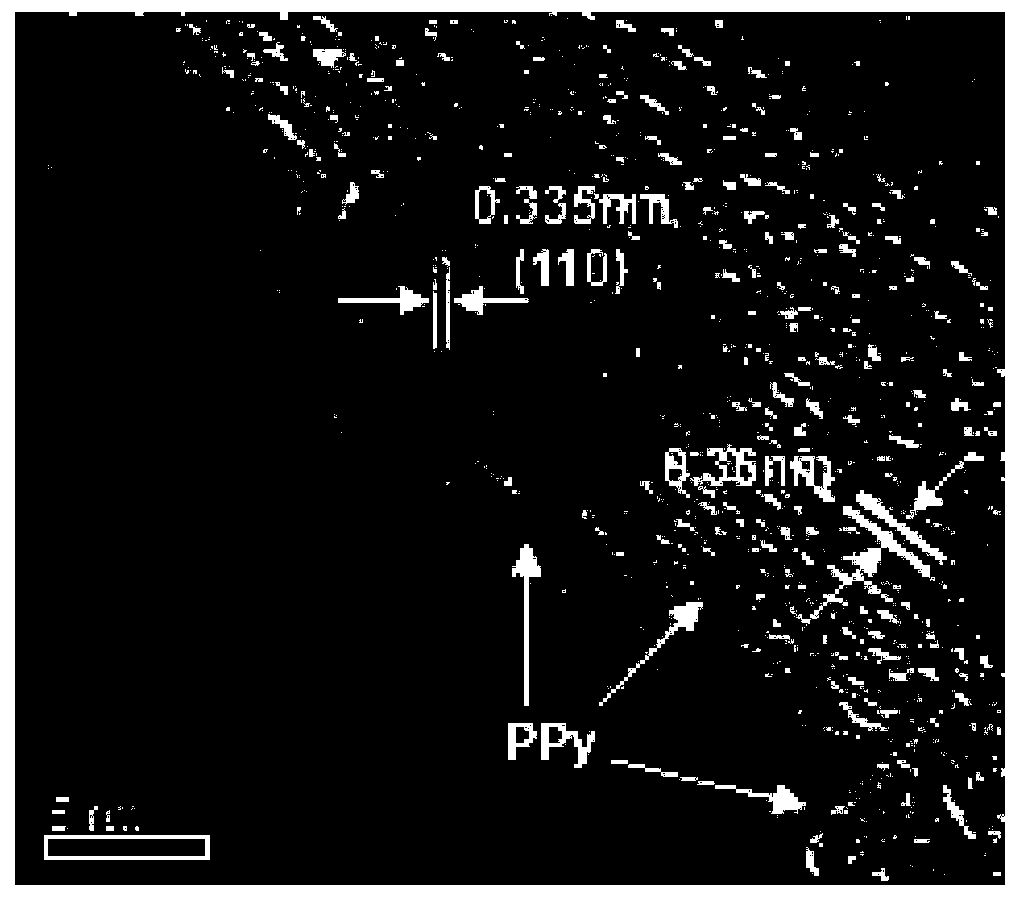

[0023] Step 2: Synthesis of hollow SnO by hydrothermal method 2 Material. Prepare 15mmol·L -1 Na 2 SnO 3 ·3H 2 O deionized water / dehydrated ethanol solution (volume ratio 5:3), add urea to make its concentration reach 0.1mol L -1 , the solution was transferred to a polytetrafluoroethylene-lined stainless steel hydrothermal kettle, heated in an electric thermostatic drying oven at 160°C for 30 hours, and cooled naturally. °C drying, and then heat treatment at 500 °C in a tube furnace for 1 h, the obtained SnO 2 hollow microspheres;

[0024] Step 3: Synthesis of novel SnO by in situ polymerization 2 / graphene / PPy ternary composites. 0.1g hollow SnO 2 The microspheres were mixed into 40 mL deionized aqueous solution containing 4 mg sodium lauryl sulfate and 0.025 g graphene, sonicated for 30 min, and then magnetically stirred for 3 h. Afte...

Embodiment 3

[0026] The 1st step, the step of synthesizing graphene material with redox method is identical with the 1st step in embodiment 1;

[0027] Step 2: Synthesis of hollow SnO by hydrothermal method 2Material. Prepare 10mmol·L -1 Na 2 SnO 3 ·3H 2 O deionized water / dehydrated ethanol solution (volume ratio 5:3), add urea to make its concentration 0.1mol L -1 , the solution was transferred to a polytetrafluoroethylene-lined stainless steel hydrothermal kettle, heated in an electric thermostatic drying oven at 200°C for 24 hours, and cooled naturally. °C drying, and then heat treatment at 500 °C in a tube furnace for 1 h, the obtained SnO 2 hollow microspheres;

[0028] Step 3: Synthesis of novel SnO by in situ polymerization 2 / graphene / PPy ternary composites. 0.1g hollow SnO 2 The microspheres were mixed into 40 mL deionized aqueous solution containing 4 mg sodium dodecylsulfonate and 0.01 g graphene, sonicated for 30 min, and then magnetically stirred for 3 h. Afterwards...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com