Preparation of high-capacity molybdenum selenide-chlorella derived carbon less-layer compound battery cathode material

A composite material, battery negative electrode technology, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve the problems of poor conductivity of molybdenum selenide, poor long-term cycle stability, easy structure collapse, etc., to reduce water body The effect of pollution, improving electron conductivity, suppressing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Weigh 2 g of chlorella and 6 g of phosphomolybdic acid into 0.4 L of distilled water, stir rapidly for 12 hours, centrifuge once with water and dry in an oven at 60 °C;

[0031] 2) Grind the brown-green massive solid obtained in step 1) to powder, then weigh the brown-green solid powder and selenium powder with a mass ratio of 1:2 and place them in different corundum boats, and place them in Ar 95% / H 2 Calcined at 600°C for 2 hours in a 5% atmosphere tube furnace to collect a black solid sample, which is a few-layer molybdenum selenide-chlorella-derived carbon composite;

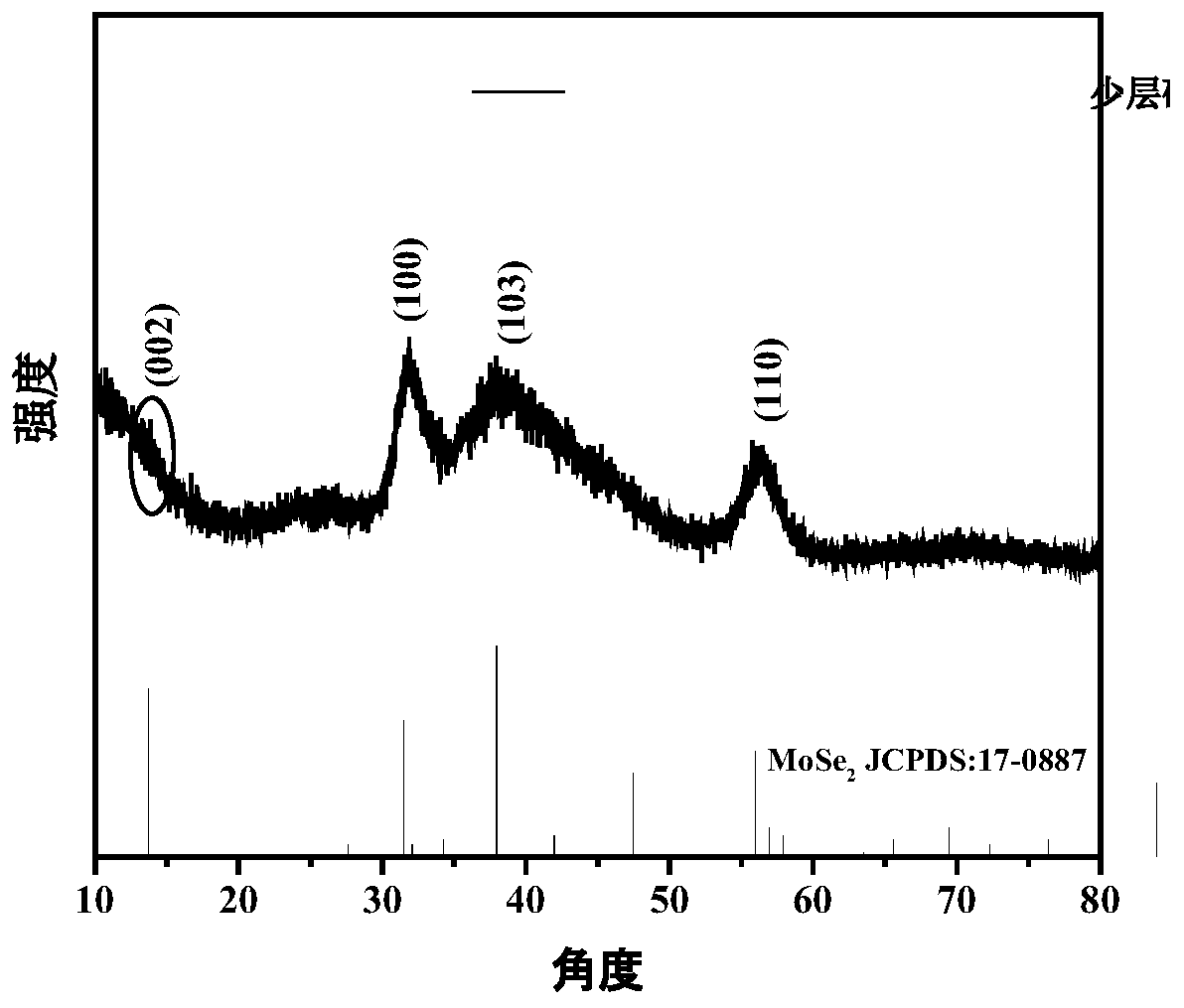

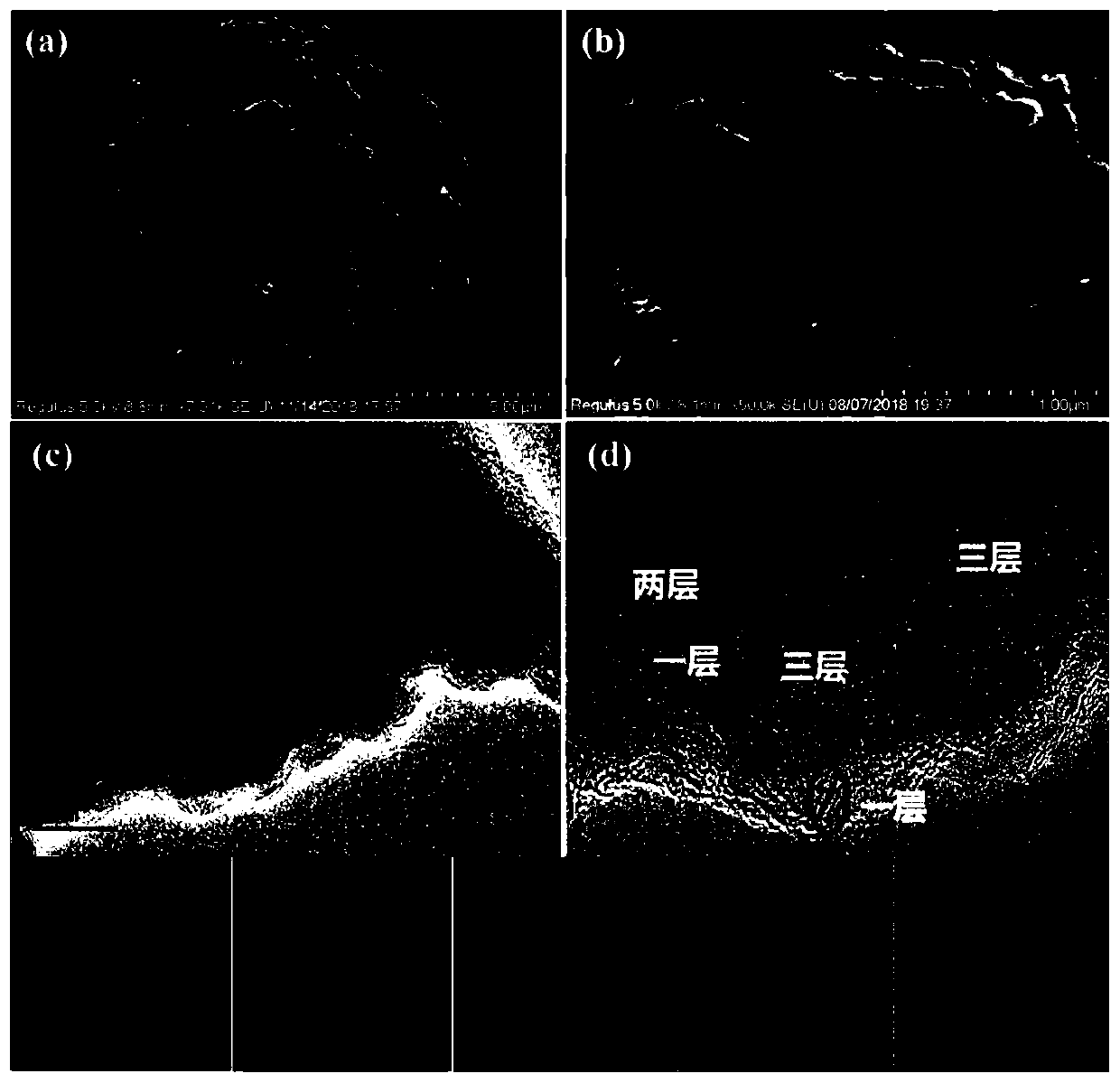

[0032] Obtained by XRD experiment figure 1 The XRD pattern of the few-layer molybdenum selenide-chlorella-derived carbon complex, by figure 1 It can be seen that the prepared material is molybdenum selenide, and its diffraction peak position matches the standard spectrum of molybdenum selenide (JCPDS, 17-0887). It can be seen from the figure that the diffraction peak is very broad, indicating th...

Embodiment 2

[0035] 1) Weigh 2 g of chlorella and 8 g of sodium molybdate into 0.6 L of distilled water, stir rapidly for 6 h, centrifuge once with water and dry in an oven at 80 °C;

[0036] 2) Grind the brown-green blocky solid obtained in step 1) to powder, then weigh the brown-green solid powder and selenium powder with a mass ratio of 1:3 and place them in different corundum boats, and place them in Ar 95% / H 2 Calcined at 500°C for 2 hours in a 5% atmosphere tube furnace to collect a black solid sample, which is a few-layer molybdenum selenide-chlorella-derived carbon composite;

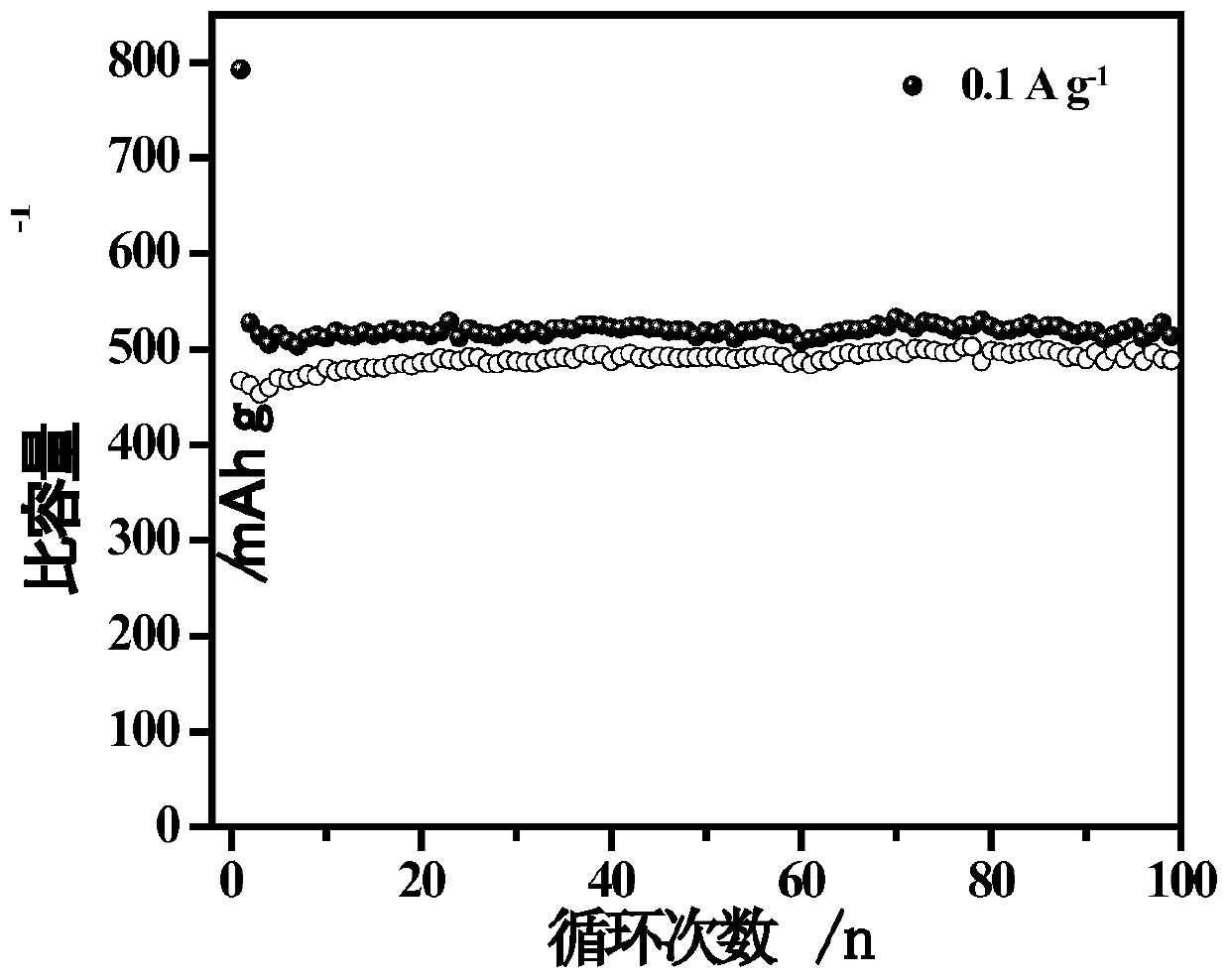

[0037] The few-layer molybdenum selenide-chlorella-derived carbon composite prepared in this example: conductive agent super P carbon: binder CMC is mixed and ground according to the mass percentage of 80 : 10 : 10, and then evenly coated on the copper foil for work Electrode, metal sodium sheet as counter electrode and reference electrode, 1 mol / L NaClO 4 / PC+EC Assembled coin cells for the electrolyte; a...

Embodiment 3

[0039] 1) Weigh 2 g of chlorella and 6 g of phosphomolybdic acid into 0.4 L of distilled water, stir rapidly for 12 hours, centrifuge once with water and dry in an oven at 70 °C;

[0040] 2) Grind the brown-green blocky solid obtained in step 1) to powder, then weigh the brown-green solid powder and selenium powder with a mass ratio of 1:2 and place them in different corundum boats, and place them in Ar 95% / H 2 Calcined in a 5% atmosphere tube furnace at 700°C for 3 hours, collected a black solid sample, which was a few-layer molybdenum selenide-chlorella-derived carbon composite;

[0041] The few-layer molybdenum selenide-chlorella-derived carbon composite prepared in this example: conductive agent super P carbon: binder CMC is mixed and ground according to the mass percentage of 80 : 10 : 10, and then evenly coated on the copper foil for work Electrode, metal sodium sheet as counter electrode and reference electrode, 1 mol / L NaClO 4 / PC+EC Assembled coin cells for the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com