High nickel positive electrode material with uniform coating layer and preparation method thereof

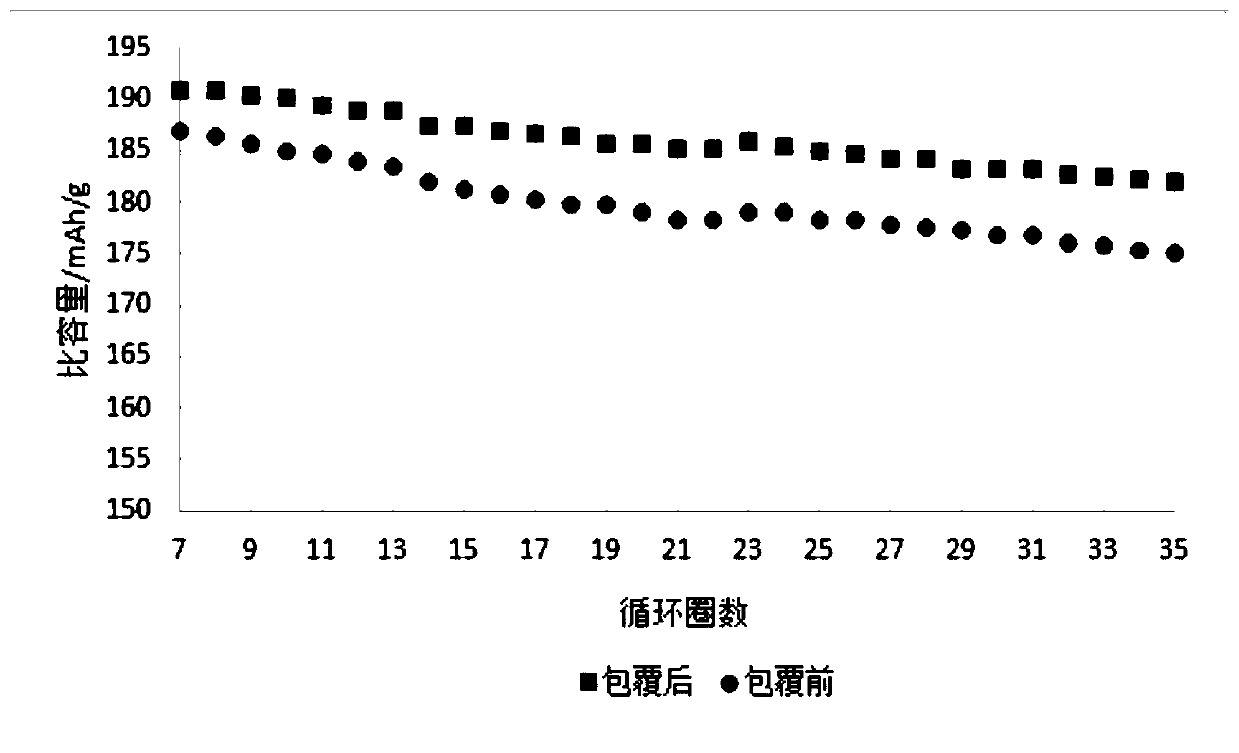

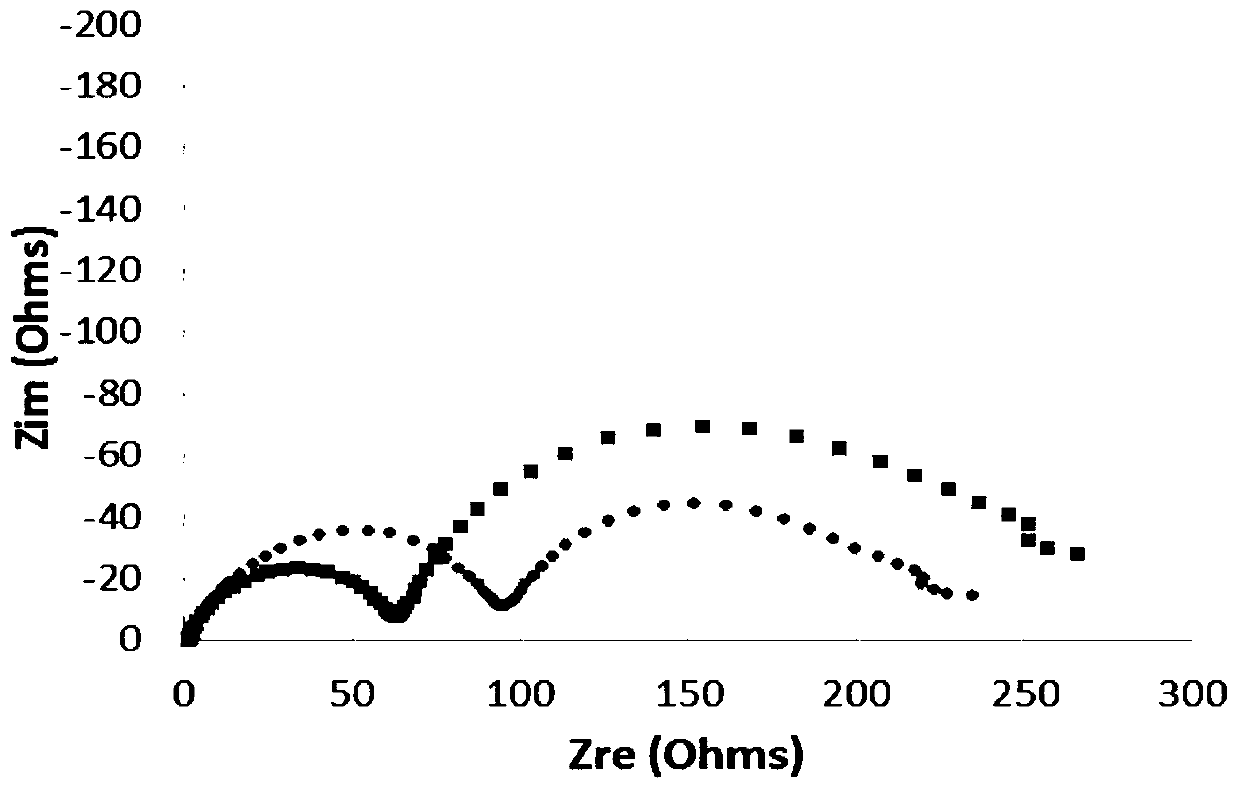

A technology of positive electrode material and coating layer, which is applied in the field of high nickel positive electrode material and its preparation, can solve the problems of low safety, poor cycle stability, complicated preparation process, etc., and achieve the reduction of production cost and time, safety and stability Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

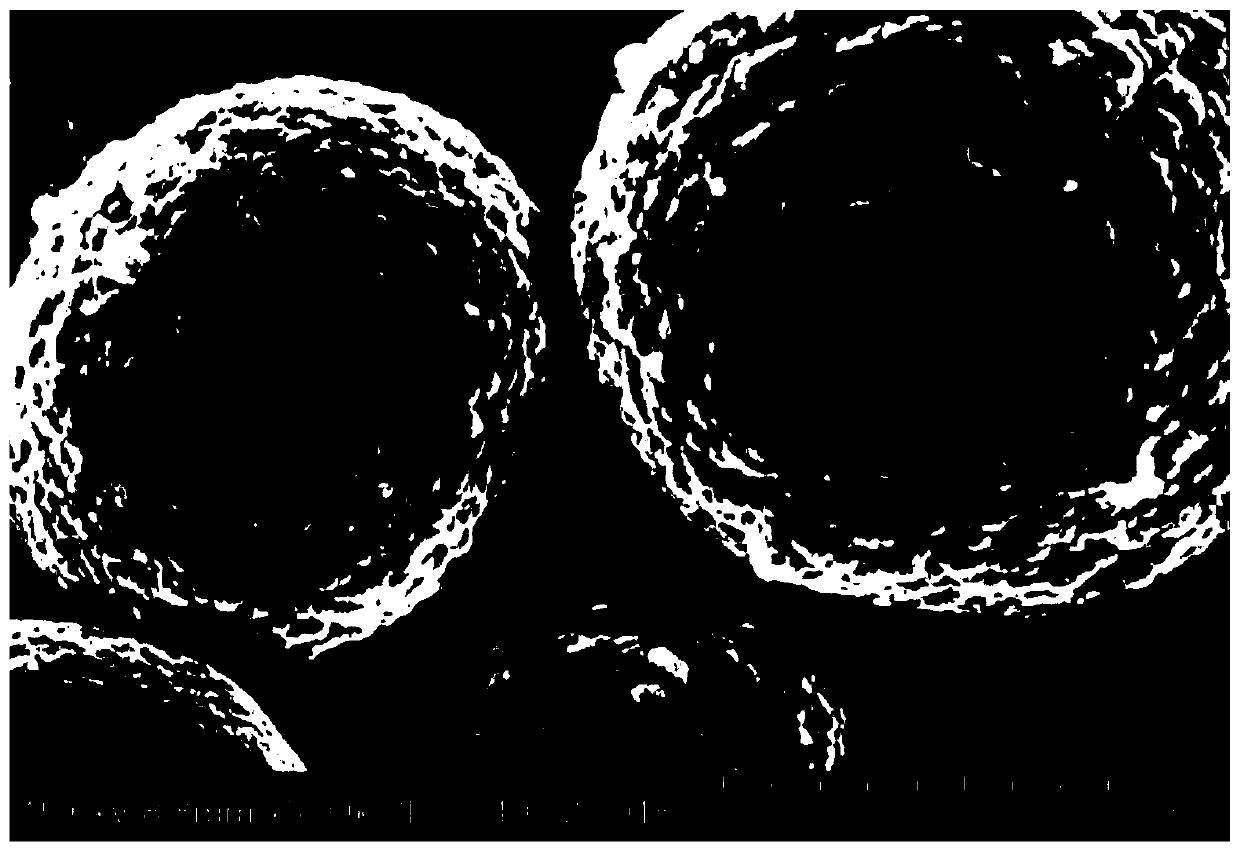

Embodiment 1

[0075] Add 200g of deionized water and high-nickel positive electrode active material LiNi into a 1L beaker 0.80 co 0.10 mn 0.10 o 2 200g, stirring speed 300r / min, to be stirred evenly. Add slowly (NH 4 ) 2 HPO 4 2.16g, after stirring evenly, slowly add Ba(NO 3 ) 2 6.27g The stirring speed remains unchanged, and the stirring is preferably continued for 15 minutes. Filter the obtained mixture, filter it with a vacuum water pump, wash it with 20 mL of absolute ethanol, drain it, and dry it in a blast oven at 65°C for 3 hours to obtain a dry material, which is placed in a sagger and heated in a preheated muffle furnace. Sintering reaction at 700°C for 10h under oxygen atmosphere (oxygen concentration ≥ 80%). Cool slowly, crush and sieve to obtain a high-nickel positive electrode material active material with a uniform coating layer.

Embodiment 2

[0077] Add 200g of deionized water and high-nickel positive electrode active material LiNi into a 1L beaker 0.90 co 0.05 mn 0.05 o 2 200g, stirring speed 300r / min, to be stirred evenly. Add slowly (NH 4 ) 2 HPO 4 2.16g, stir well and slowly add MgCl 2 ·6H 2 O4.88g The stirring speed is constant, and the stirring is preferably continued for 15 minutes. Filter the obtained mixture, filter it with a vacuum water pump, wash it with 20 mL of absolute ethanol, drain it, and dry it in a blast oven at 65°C for 3 hours to obtain a dry material, which is placed in a sagger and heated in a preheated muffle furnace. Sintering reaction at 700°C for 10h under oxygen atmosphere (oxygen concentration ≥ 80%). Cool slowly, crush and sieve to obtain a high-nickel cathode material active material LiNi with a uniform coating layer 0.90 co 0.05 mn 0.05 o 2 .

Embodiment 3

[0079] Add 200g of deionized water and high-nickel positive electrode active material LiNi into a 1L beaker 0.80 co 0.10 mn 0.10 o 2 200g, stirring speed 200r / min, to be stirred evenly. Add slowly (NH 4 ) 2 HPO 4 2.16g, after stirring evenly, slowly add Al(NO 3 ) 3 9H 2 O 6.00g The stirring speed remains unchanged, and the stirring is preferably continued for 15 minutes. Filter the obtained mixture, filter it with a vacuum water pump, wash it with 20 mL of absolute ethanol, drain it, and dry it in a blast oven at 65°C for 3 hours to obtain a dry material, which is placed in a sagger and heated in a preheated muffle furnace. Sintering reaction at 700°C for 10h under oxygen atmosphere (oxygen concentration ≥ 80%). Cool slowly, crush and sieve to obtain a high-nickel cathode material active material LiNi with a uniform coating layer 0.80 co 0.10 mn 0.10 o 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com