FeNi-S@N-RGO nanosheet supercapacitor electrode material and preparation method thereof

A technology for supercapacitors and electrode materials, applied in the fields of electrochemistry and nanomaterials, can solve the problems of uncontrollable conductivity, difficulty in compounding, hindering the application of graphene, etc., to improve physical and chemical properties, good dispersion, and improve electrochemical performance. effect of nature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

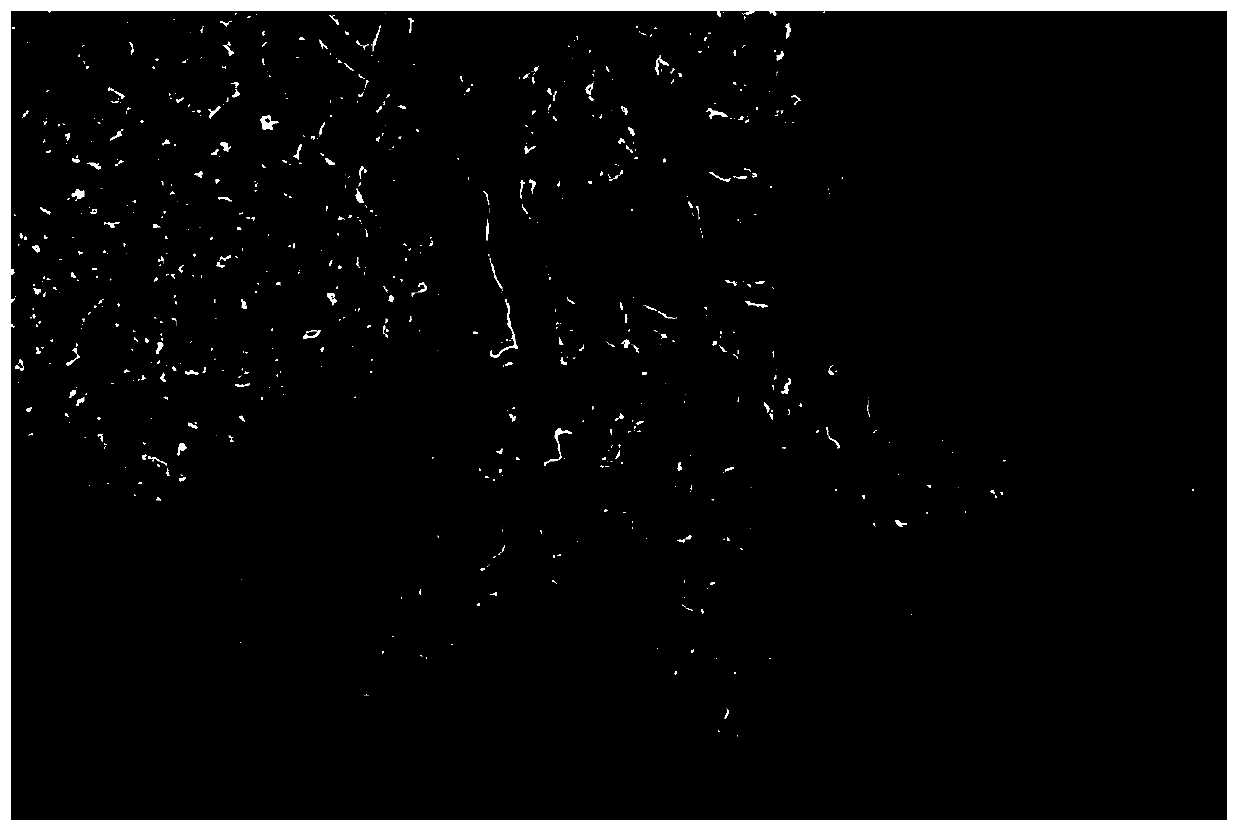

Image

Examples

Embodiment 1

[0032] A preparation method of FeNi-S@N-RGO nanosheet supercapacitor electrode material, comprising the following steps: First, 0.29ml of 1M NiCl 2 ·6H 2 O, 2.9ml of 1M Fe(NO 3 ) 3 9H 2 O, 11.2ml of 0.5M CH 4 N 2 O, 4ml of 0.1M C 6 h 5 Na 3 o 7 (The molar ratio is 1:20:5:2) in a 250ml beaker, and inject 160ml of deionized water. After it was completely dissolved, it was transferred to a 200ml polytetrafluoroethylene-lined stainless steel autoclave for the first step of hydrothermal reaction. The hydrothermal reaction temperature was 150°C and the hydrothermal reaction time was 24h. The obtained FeNi LDH samples were centrifuged, washed three times with water, and dried. Weigh 80mg of FeNiLDH sample, dissolve it in 40ml of ethanol, add 0.1125g of thioacetamide, mix evenly and transfer it to a 200ml polytetrafluoroethylene-lined stainless steel autoclave for the second hydrothermal reaction. The hydrothermal reaction temperature is 120°C; the hydrothermal reaction tim...

Embodiment 2

[0036] A FeNi-S@N-RGO nanosheet supercapacitor electrode material and a preparation method thereof, comprising the following steps: First, 0.29ml of 1M NiCl 2 ·6H 2 O, 2.9ml of 1M Fe(NO 3 ) 3 9H 2 O, 11.2ml of 0.5M CH 4 N 2 O, 4ml of 0.1MC 6 h 5 Na 3 o 7(The molar ratio is 1:20:5:2) in a 250ml beaker, and inject 160ml of deionized water. After it was completely dissolved, it was transferred to a 200ml polytetrafluoroethylene-lined stainless steel autoclave for the first step of hydrothermal reaction. The hydrothermal reaction temperature was 150°C and the hydrothermal reaction time was 24h. The obtained FeNi LDH samples were centrifuged, washed three times with water, and dried. Weigh 80mg of FeNiLDH sample, dissolve it in 40ml of ethanol, add 0.1125g of thioacetamide, mix evenly and transfer it to a 200ml polytetrafluoroethylene-lined stainless steel autoclave for the second hydrothermal reaction. The hydrothermal reaction temperature is 120°C, the reaction time is...

Embodiment 3

[0040] A FeNi-S@N-RGO nanosheet supercapacitor electrode material and a preparation method thereof, comprising the following steps: First, 0.29ml of 1M NiCl 2 ·6H 2 O, 2.9ml of 1M Fe(NO 3 ) 3 9H 2 O, 11.2ml of 0.5M CH 4 N 2 O, 4ml of 0.1M C 6 h 5 Na 3 o 7 (The molar ratio is 1:20:5:2) in a 250ml beaker, and inject 160ml of deionized water. After it was completely dissolved, it was transferred to a 200ml polytetrafluoroethylene-lined stainless steel autoclave for the first step of hydrothermal reaction. The hydrothermal reaction temperature was 150°C and the hydrothermal reaction time was 24h. The obtained FeNi LDH samples were centrifuged, washed three times with water, and dried. Weigh 80mg of FeNiLDH sample, dissolve it in 40ml of ethanol, add 0.1125g of thioacetamide, mix evenly and transfer it to a 200ml polytetrafluoroethylene-lined stainless steel autoclave for the second hydrothermal reaction. The hydrothermal reaction temperature is 120°C, the reaction time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com