High-temperature micro-pressure pressure sensor, and manufacturing method and measuring system thereof

A technology of pressure sensor and sensor chip, which is applied in the direction of fluid pressure measurement, measuring device, and fluid pressure measurement by changing the ohmic resistance, which can solve the problems of large repeatability error, low linearity, and poor sensitivity, and achieve piezoresistive effect Larger, improved linearity, increased sensitivity and linearity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

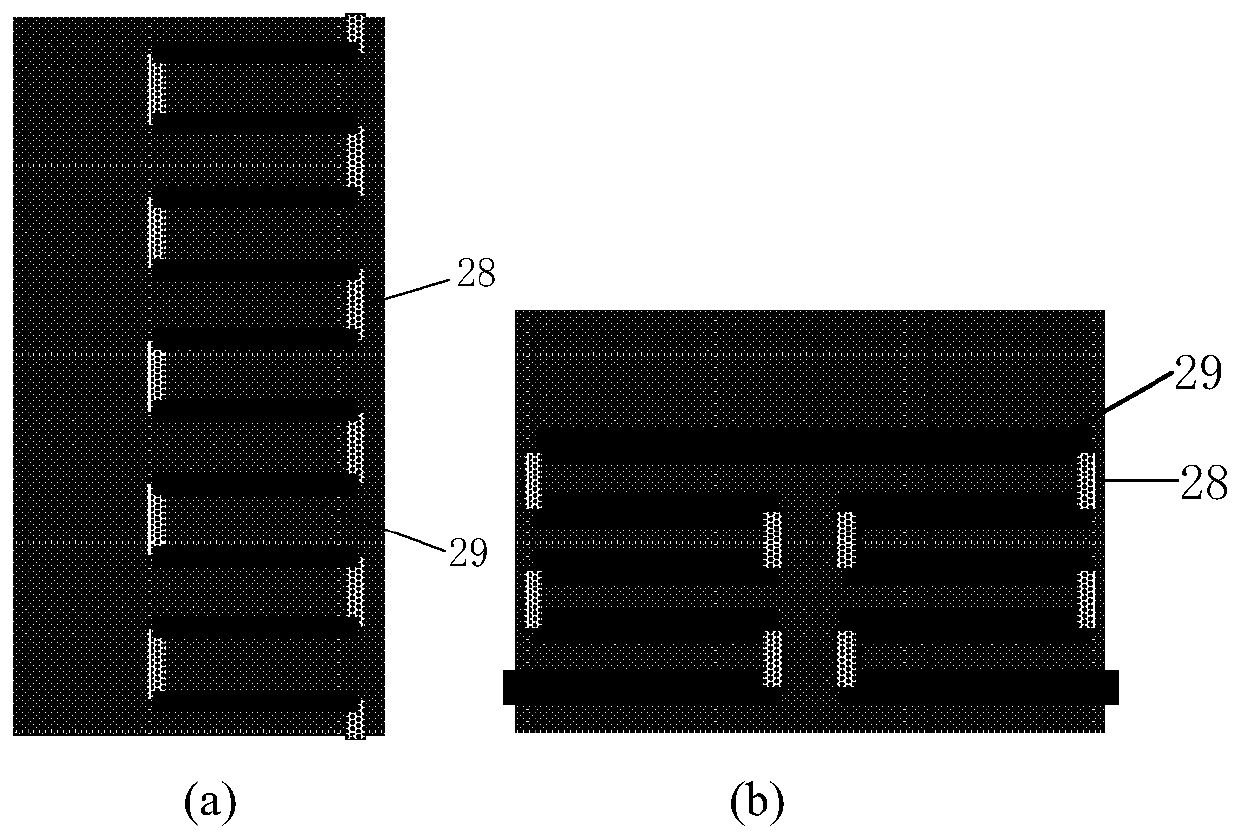

[0049] The technical solutions and beneficial effects of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0050] Such as figure 1 As shown, the present invention provides a high-temperature micro-pressure pressure sensor, including a sensor chip, a left compensation circuit 1, a right compensation circuit 2, a power supply electrode to the positive pole 3, a power supply electrode to the negative pole 4, and a signal detection lead-out electrode to the positive pole 5, The signal detection lead-out electrode pair negative electrode 6, the glass bottom support layer 7, the stainless steel bottom 8 and the plastic shell 9 are introduced respectively below.

[0051] The overall sensor chip is rectangular, including a silicon bottom layer 10 , a silicon dioxide insulating layer 11 , a silicon carbide top layer 12 , and an uppermost cavity sealing layer 13 stacked sequentially from bottom to top. The lower part of the silicon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com