A Composite Interface Pre-tightened Connection High Performance Steel-UHPC Thin Plate Composite Structural System

A combined structure and high-performance technology, applied in bridge materials, buildings, bridge construction, etc., can solve problems such as complex construction process and inconvenient implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

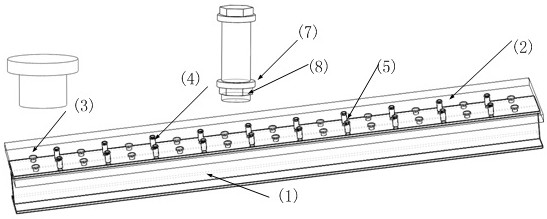

[0030] The invention is a composite interface pre-tightening connection high-performance steel-UHPC thin plate composite structure system and an interface connection technology adapted thereto. The structural system mainly includes the UHPC sheet 2 laid on the steel beam 1 and the large-diameter studs 3 and high-strength friction bolts 4 arranged on the steel beam 1. Finally, the large-diameter studs 3 are embedded in the UHPC sheet 2, The high-strength bolt 4 connects the UHPC thin plate 2 and the steel beam 1 as a whole through the nut 7 and the washer 8, and in the transverse direction of the interface, the connecting parts are symmetrically arranged about the longitudinal center line, and finally the steel beam 1 and the UHPC thin plate 2 pass through the interface. Composite shear connectors form a new composite structure system.

[0031] The numbers of studs 3 and high-strength bolts 4 are obtained by calculation. The studs 3 and bolts 4 are arranged at equal intervals a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com