Chitin polyester fiber

A polyester fiber and chitin technology, applied in the fiber field, can solve the problems of many rabbits, affecting the unwinding performance of the winding drum, and the loss of chitin on the fiber surface, achieving long-lasting antibacterial and bacteriostatic properties, preventing broken heads and wool, the effect of improving the winding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

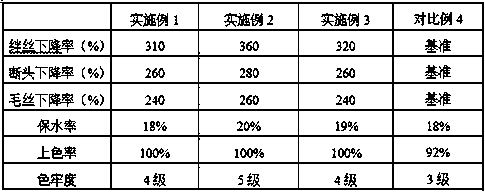

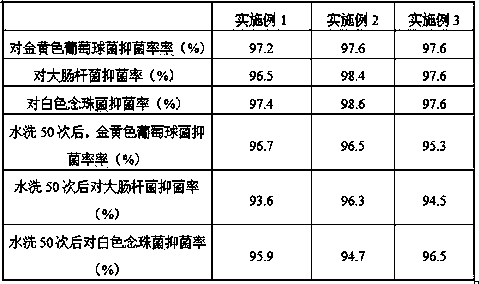

Embodiment 1

[0034] Embodiment 1 A kind of chitin polyester fiber, its raw material comprises polyester chip, chitosan, modifier, regulator; The mass ratio of described polyester chip, chitosan, modifier, regulator is 75 :3:5.5:1.5;

[0035] The polyester chips mentioned above: water content ≤0.2%, acetaldehyde content ≤1%, acid value max.35Meq / kg, intrinsic viscosity 0.865±0.015dl / g, purchased from Suzhou Lijuncheng Plastics Import & Export Co., Ltd. , item number: LJC-CB-608S; said chitosan: deacetylation degree ≥ 95%, moisture content ≤ 80.5%, viscosity ≤ 50mpa.s;

[0036] Described modifying agent is made up of triethyl citrate, talcum powder, potassium methyl silicate, guar gum; Preferably, in described modifying agent, triethyl citrate, talcum powder, methyl silicate The preferred ratio of potassium to guar gum is 17:1:4:2.

[0037] Described conditioning agent is made up of sodium acetate, sodium alginate, isopropanol;

[0038] The preferred mass ratio of sodium acetate, sodium a...

Embodiment 2

[0049] Embodiment 2 A kind of chitin polyester fiber, its raw material comprises polyester chip, chitosan, modifier, regulator; The mass ratio of described polyester chip, chitosan, modifier, regulator is 75 :3:5.5:1.5;

[0050] The polyester chips mentioned above: water content ≤0.2%, acetaldehyde content ≤1%, acid value max.35Meq / kg, intrinsic viscosity 0.865±0.015dl / g, purchased from Suzhou Lijuncheng Plastics Import & Export Co., Ltd. , item number: LJC-CB-608S; said chitosan: deacetylation degree ≥ 95%, moisture content ≤ 80.5%, viscosity ≤ 50mpa.s;

[0051] Described modifying agent is made up of triethyl citrate, talcum powder, potassium methyl silicate, guar gum; In described modifying agent, triethyl citrate, talcum powder, potassium methyl silicate, guar gum The preferred ratio of Er gum is 18:2:3:3.

[0052] Described conditioning agent is made up of sodium acetate, sodium alginate, isopropanol;

[0053] The preferred mass ratio of sodium acetate, sodium alginate...

Embodiment 3

[0064] Embodiment 3 A kind of chitin polyester fiber, its raw material comprises polyester chip, chitosan, modifier, regulator; The mass ratio of described polyester chip, chitosan, modifier, regulator is 85 :5:4:2.3;

[0065] The polyester chips mentioned above: water content ≤0.2%, acetaldehyde content ≤1%, acid value max.35Meq / kg, intrinsic viscosity 0.865±0.015dl / g, purchased from Suzhou Lijuncheng Plastics Import & Export Co., Ltd. , item number: LJC-CB-608S; said chitosan: deacetylation degree ≥ 95%, moisture content ≤ 80.5%, viscosity ≤ 50mpa.s;

[0066] Described modifying agent is made up of triethyl citrate, talcum powder, potassium methyl silicate, guar gum; In described modifying agent, triethyl citrate, talcum powder, potassium methyl silicate, guar gum The preferred ratio of Er gum is 20:1:4:3.

[0067] Described conditioning agent is made up of sodium acetate, sodium alginate, isopropanol;

[0068] The preferred mass ratio of sodium acetate, sodium alginate a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com