650 MPa-grade low-alloy high-strength steel and production method thereof

A production method and low-alloy technology, applied in the field of metallurgical plate production, can solve the problems of unfavorable automobile plate production cost, high consumption of alloy elements, high cost, etc., achieve low annealing cooling speed requirements, low production difficulty, and reduce the probability of stamping problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below by specific embodiment 1~10, the present invention is described in further detail:

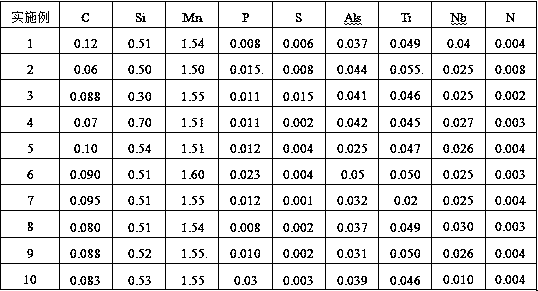

[0015] The chemical composition of the continuous casting slab used in the concrete embodiment 1~10 medium and low alloy high strength steel is as shown in table 1:

[0016] Table 1 Chemical composition (wt%)

[0017]

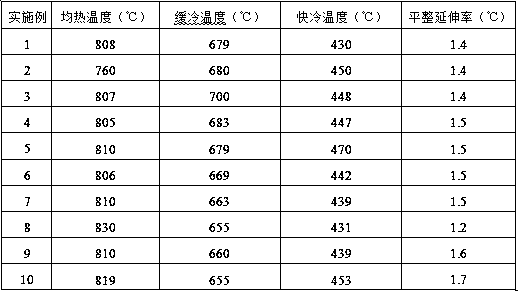

[0018] The control range of hot rolling process parameters is that the hot rolling heating temperature is 1200~1260°C, the finish rolling temperature is 876~904°C, and the coiling temperature is 613~650°C. Show:

[0019] Table 2 Hot rolling process parameters

[0020]

[0021] Using the hot rolling coiling temperature can ensure that carbon and nitride in Nb and Ti composite low-alloy high-strength steel can be precipitated with a large degree of supercooling, and ensure that the precipitates are distributed in a dispersed manner to ensure the yield and tensile strength of the finished product. the goal of;

[0022] In the cold rolling continuous annealin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com