Novel Ag-Ni electrical contact material and preparation method thereof

An electric contact material, ag-ni technology, applied in the direction of contacts, circuits, electric switches, etc., can solve the problems of material transfer service life, reduction, application restrictions, etc., to achieve improved life, excellent comprehensive performance, anti-welding good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Weigh 43 grams of silver nitrate and 3.41 grams of PVP to make 340ml solution, and prepare Na 2 CO 3 The aqueous solution of precipitating agent is dropped into the above solution to obtain Ag 2 CO 3 Precipitate the separated body and wash it several times, add deionized water, and sonicate for 30 minutes to make suspension A; weigh Ni powder (0.5-2μm)3, TiB 2 Powder ((0.5~2μm) 0.15g, add deionized water, ultrasonic 40min to make suspension B; pour suspension B into container A and stir (800 rpm) for 30min, dehydrate with alcohol, dry, grind. Finally Calcined at 350°C for 3h and ground to produce Ag-Ni-TiB 2 Composite powder. After initial pressing, initial firing, re-pressing, re-firing, second re-pressing, and second re-firing, the contact material sheet is made. After rolling and deformation, the density reaches more than 98%, the hardness is 110HV, and the arc erosion voltage is increased from 600V. to 800V.

Embodiment 2

[0059] Weigh 43 grams of silver nitrate and 3.41 grams of PVP to make a 340ml solution, add the precipitant solution dropwise into the above solution, wash it several times, add deionized water, and ultrasonically 20-40min to make a suspension A; weigh Ni powder (0.5~2μm)3g, TiB 2 Powder (0.5-2μm) 0.3g, add deionized water, ultrasonic 40min, make suspension B; pour B suspension into A container and stir (500 rpm) for 45min, alcohol dehydration, dry. Finally, it is calcined at 350°C for 3 hours and ground to obtain Ag-ZnO-TiB 2 Composite powder. After initial pressing, initial firing, re-pressing, re-firing, second re-pressing, second re-firing, and then rolling into contact materials of different thicknesses. The density reaches over 98%, the hardness is 120, and the arc erosion voltage can be increased to 1000V.

Embodiment 3

[0061] Take by weighing 43 grams of silver nitrate and 3.41 grams of PVP to make 340ml solution, add precipitant solution and drop into the above solution, wash repeatedly, add deionized water, ultrasonic 40min, make suspension A; take Ni powder (0.5 ~2 μm) 3 g, TiB 2 Powder (0.5~2μm) 0.4g, TiC powder (0.5~2μm) 0.1g, add deionized water, ultrasonic 40min, make suspension B; pour B suspension into A container and stir (600 rpm) for 40min , Alcohol dehydration, dry. Finally, it is calcined at 350°C for 3 hours and ground to obtain Ag-Ni-TiB 2 -TiC composite powder. After initial pressing, initial firing, re-pressing, re-firing, second re-pressing, second re-firing, and then rolling to obtain finished products. The hardness is 115HV, and the density reaches 98%.

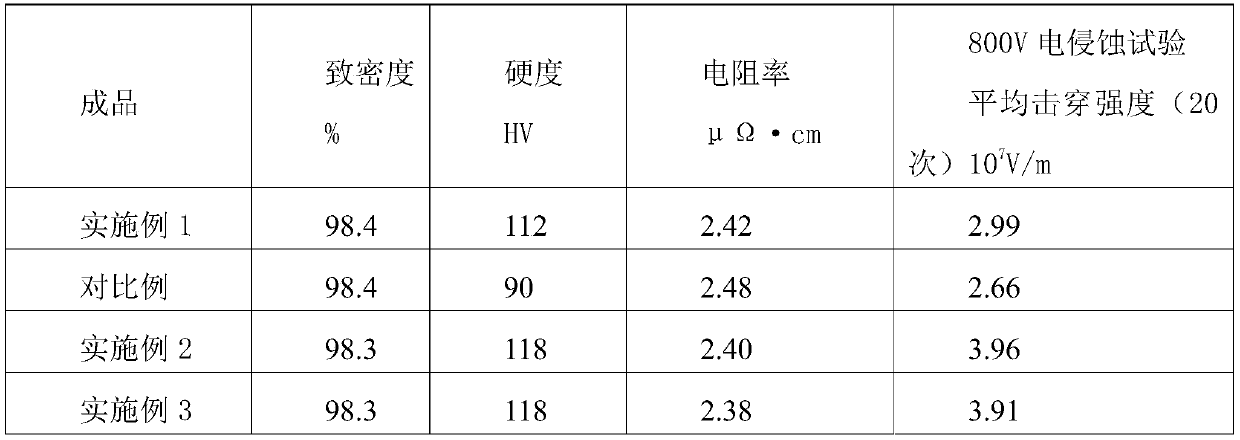

[0062] Attached Table 1 Performance Comparison of Embodiments

[0063]

[0064] Through the above simple preparation process, a new type of Ag-Ni-TiB with excellent performance can be prepared 2 +TiC electrical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com