Viscoelastic damper plate vulcanizing mold

A technology of flat plate vulcanization and damper, which is applied in the field of engineering structures, can solve the problems of hindering the popularization and application of viscoelastic dampers, inconvenient processing, high production cost, etc., and achieve the effects of facilitating popularization and application, simple structure and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

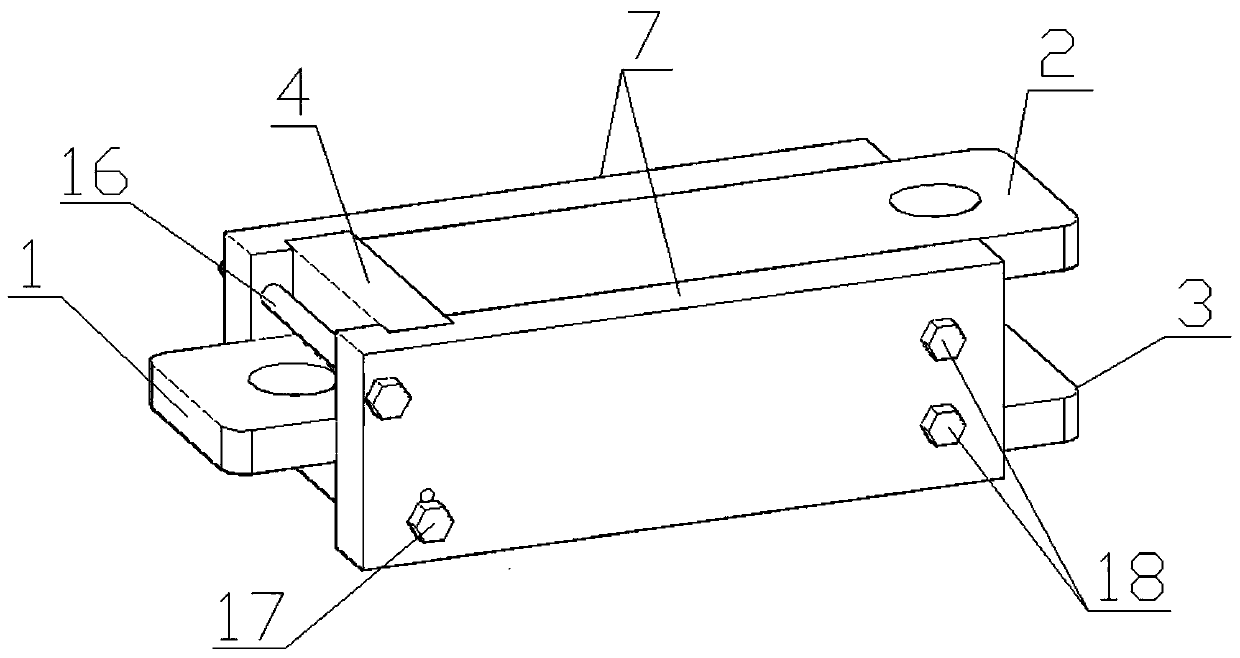

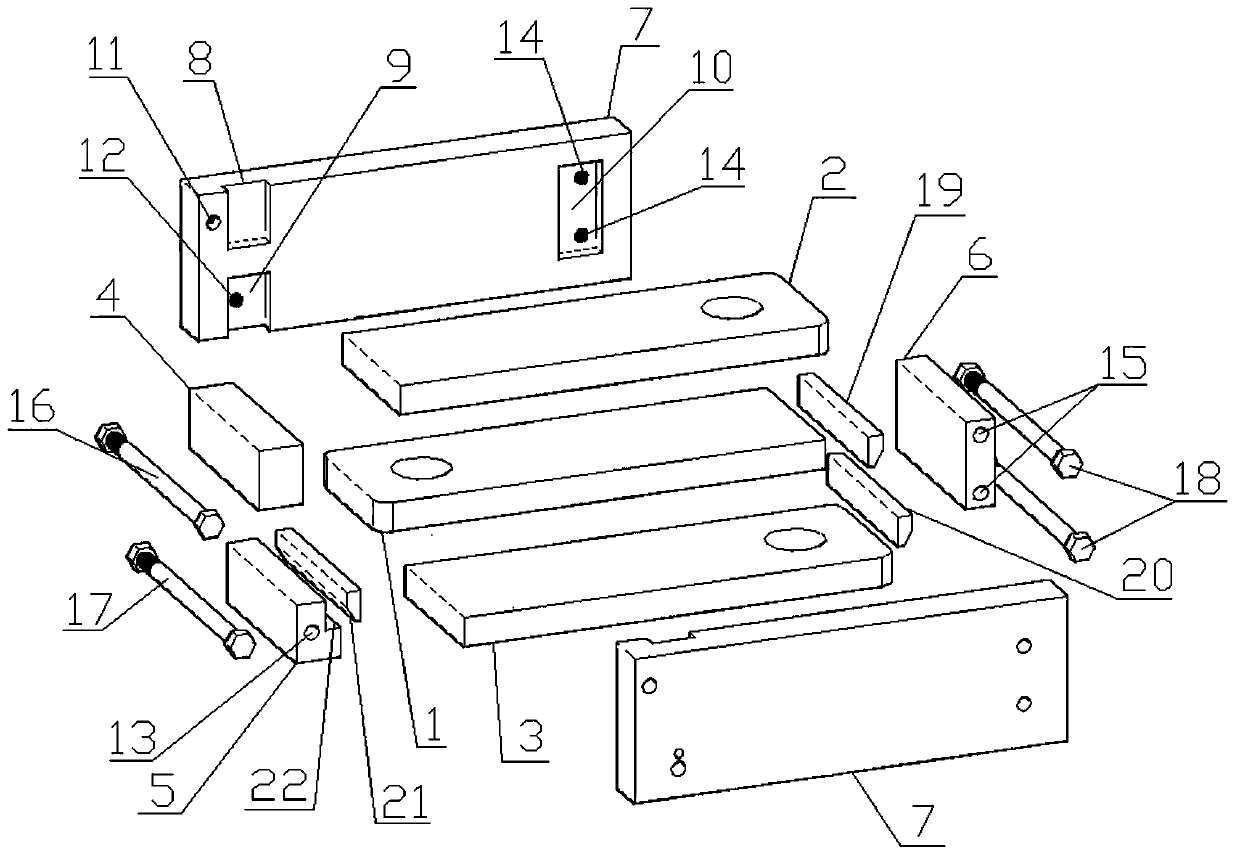

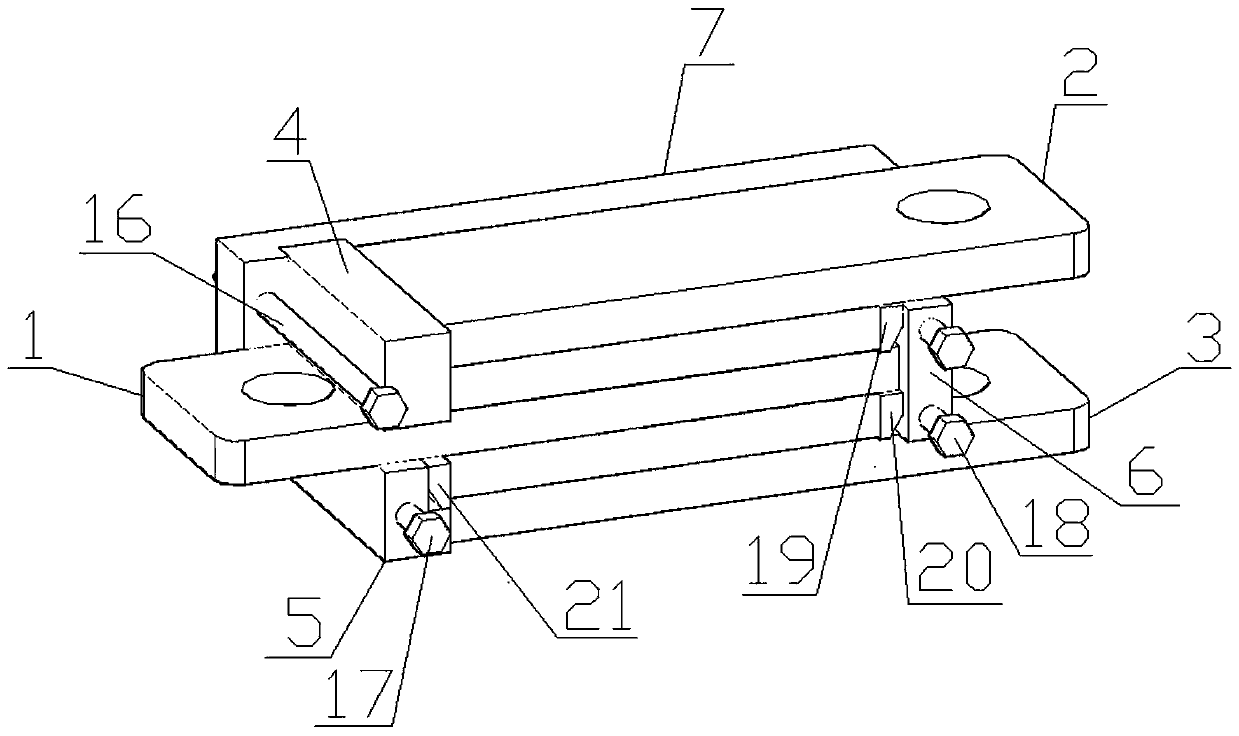

[0023] Such as Figure 1 to Figure 3 As shown, a viscoelastic damper plate vulcanization mold includes a middle formwork 1, an upper formwork 2, a lower formwork 3 and a special side form, which also serve as a damping steel plate, and also includes a left limiting plate A4, a left limiting plate B5, a right Limiting plate 6, locking bolt A16, locking bolt B17 and locking bolt C18, the upper template 2, the lower template 3 and the middle template 1 are all rectangular; Plate 7 composition;

[0024] Two side baffles 7 are provided with a pair of left limiting grooves A8 and a pair of left limiting grooves B9 at intervals on the upper and lower sides of the left part on the opposite side, and a pair of left limiting grooves B9 are provided on the middle part of the right part on the opposite side. Right limiting groove 10; two side baffles 7 are provided with a pair of thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com