Chemical equipment tail gas treatment device

A technology for tail gas treatment and chemical equipment, which is applied in the direction of combined devices, chemical instruments and methods, and separation of dispersed particles. It can solve problems such as inconvenience, complex structure, and short residence time of flue gas, so as to prevent packing compaction and increase processing paths. , the effect of prolonging the processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

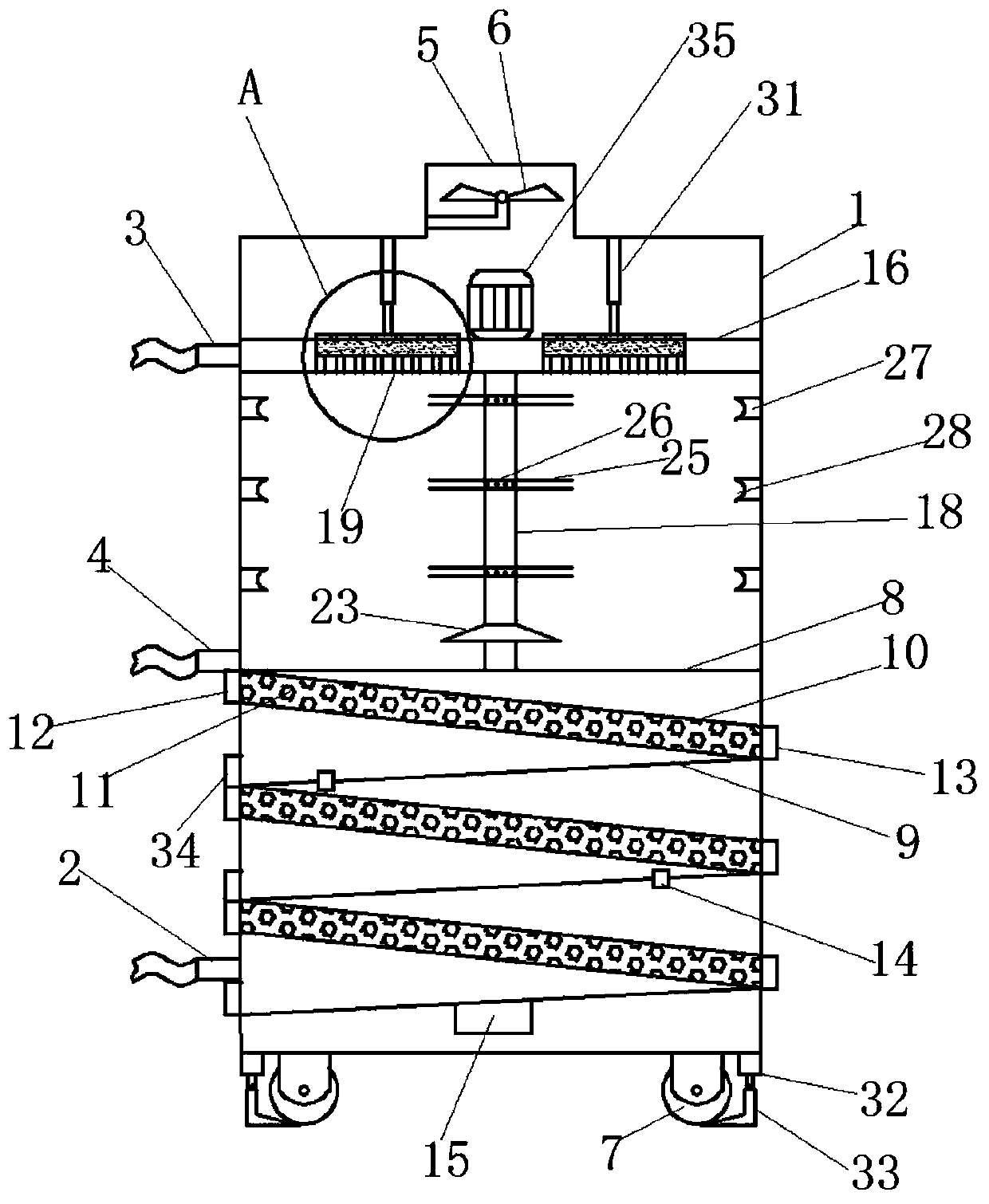

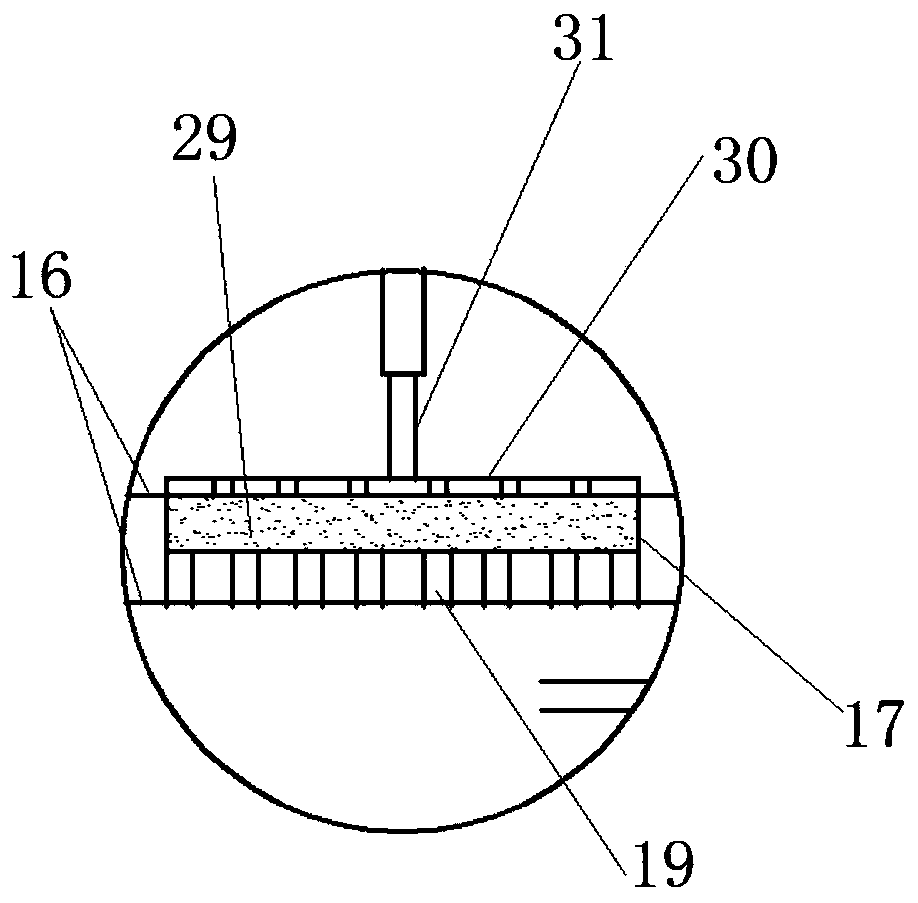

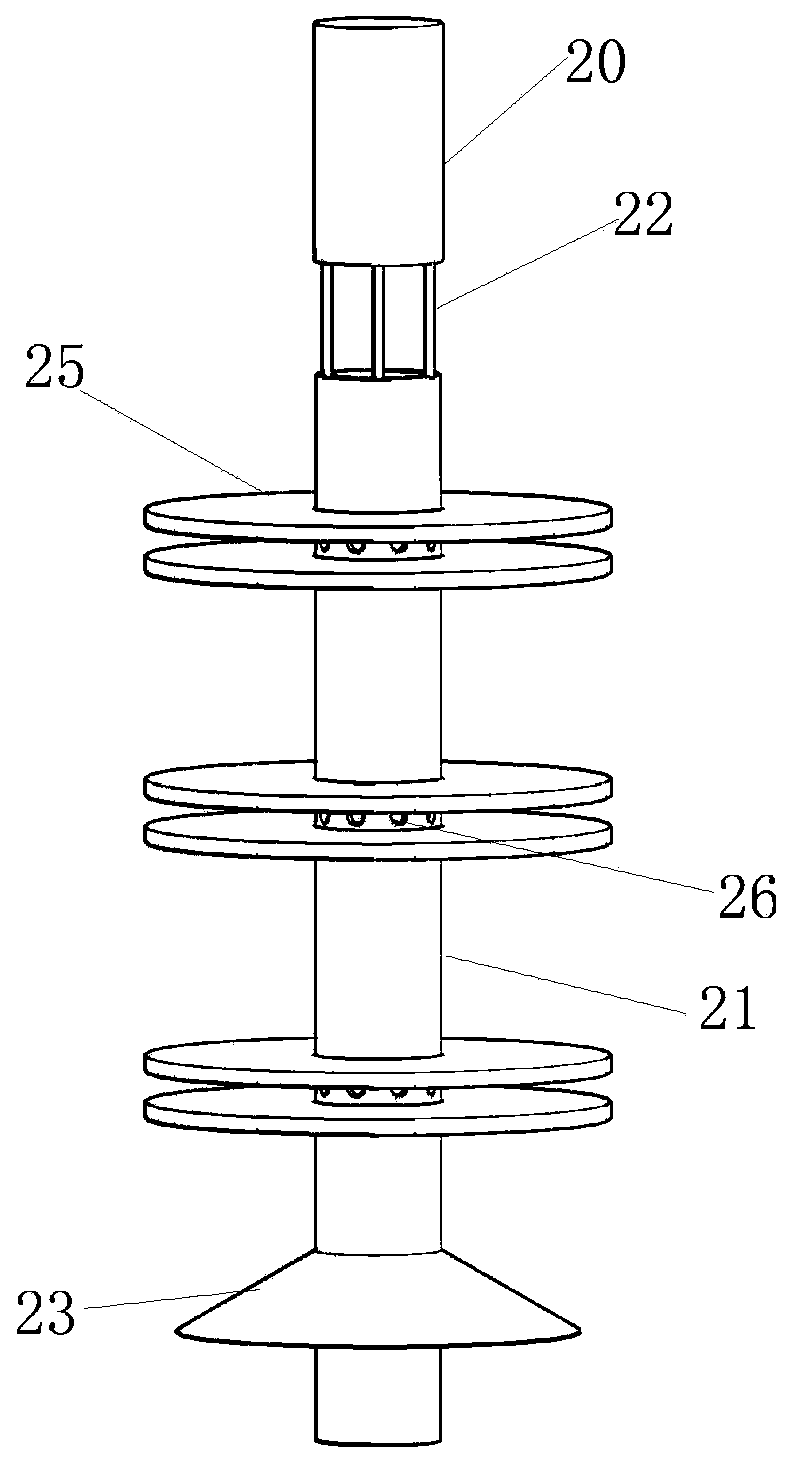

[0028] Such as Figure 1-5 In the shown embodiment, a chemical equipment tail gas treatment device includes a casing 1, a raw flue gas inlet pipe 2 arranged on the side of the casing 1, a water inlet pipe 3, a sewage pipe 4, and a clean smoke pipe arranged on the top of the casing 1. The gas exhaust outlet 5, the exhaust fan 6 arranged in the clean smoke exhaust outlet 5, and the walking wheel 7 arranged at the bottom of the housing 1, the middle end of the housing 1 is provided with a transverse partition 8, and the housing 1 A water delivery mechanism is fixed at the middle and upper end, and the horizontal partition 8 and the water delivery mechanism divide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com