Multi-function suction gun for leak detection with self-wrapping probe and adjustable inlet pressure

An inlet pressure and multi-functional technology, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problems of unreliable adjustment method, broken filament, and difficult coating , to avoid the risk of excess control, to avoid operational errors, and to achieve the effect of convenient and quick single-point leak detection test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings. These descriptions are only exemplary and are not intended to limit the protection scope of the present invention.

[0030] Compared with the leak detection suction gun in the prior art, the key improvement of the present invention lies in the improvement of the leak detection process and function brought about by the structural part of the self-covering probe, the structural part of the adjustable flow valve and the connection relationship between them. Variety.

[0031] 1. The structure of the self-covering probe

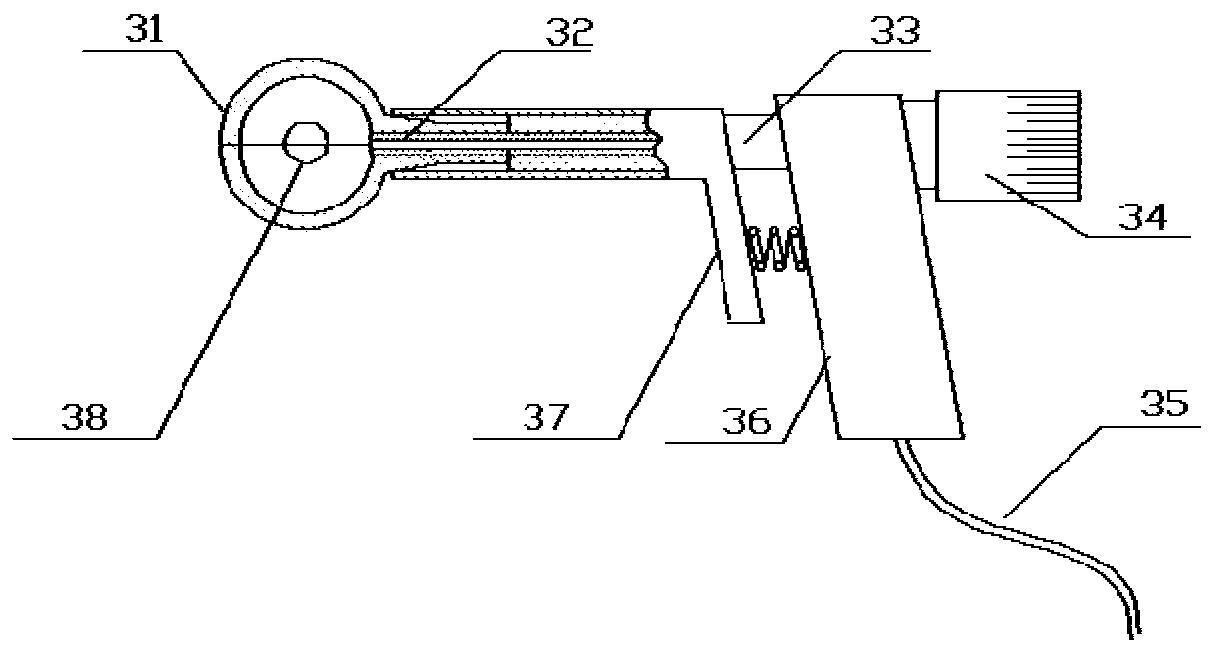

[0032] see image 3 , image 3 Shows a schematic structural diagram of a self-covering probe and a multifunctional leak detection sniffer with adjustable inlet pressure; wherein, the multifunctional leak detection sniffer with a self-covered probe and an adjustable inlet pressure includes a self-covered probe, 31 , Sniffer le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com