Preparation method and application of water-based lubricant using graphene quantum dots as additive

A graphene quantum dot, water lubricant technology, applied in the directions of additives, lubricating compositions, petroleum industry, etc., can solve the problems of poor lubricating performance, limited development, application limitations of water lubricants, etc., to achieve reliable quality, stable process, Easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

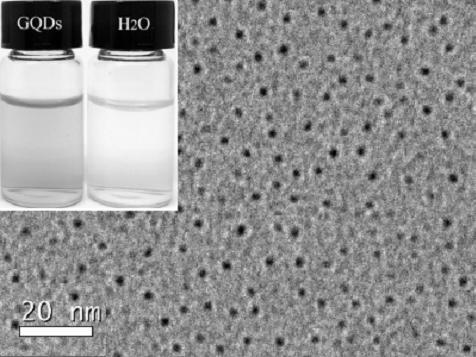

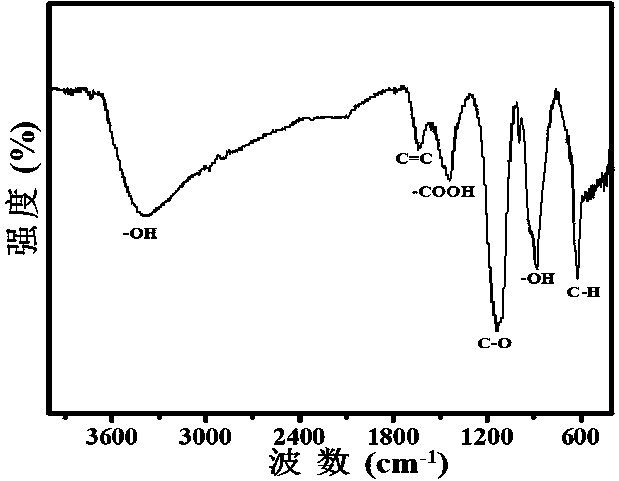

[0033] Example 1 Preparation of a water lubricant with graphene quantum dots as an additive. At room temperature, graphene quantum dots (GQDs) were added to ultrapure water to form an aqueous solution with a uniform and stable concentration of 0.5 mg / mL, namely Get water lubricant.

[0034] Among them: Graphene quantum dots are prepared according to the following method:

[0035] (1) After heating the graphite oxide powder at 300°C, disperse it in a sulfuric acid solution with a mass concentration of 96%. After sonicating at 20°C for 2h, add a 65% nitric acid solution with a mass concentration of nitric acid for 10h to obtain a mixed solution.

[0036] Among them: the mass-volume ratio of graphite oxide powder and sulfuric acid solution (mg / mL) is 1:0.2; the mass-volume ratio of graphite oxide powder and nitric acid solution (mg / mL) is 1:0.6.

[0037] ⑵ Add 6 times the volume of ultrapure water to the mixed solution, mix well, cool to room temperature, filter and wash with suction to ...

Embodiment 2

[0041] Example 2 Preparation of a water lubricant with graphene quantum dots as an additive. At room temperature, graphene quantum dots (GQDs) were added to ultrapure water to form an aqueous solution with a uniform and stable concentration of 4 mg / mL, namely Get water lubricant.

[0042] Among them: Graphene quantum dots are prepared according to the following method:

[0043] (1) After heating the graphite oxide powder at 300°C, disperse it in a sulfuric acid solution with a mass concentration of 96%. After 5 hours of ultrasonication at 25°C, add a 65% solution of nitric acid with a mass concentration of nitric acid and continue ultrasonication for 20 hours to obtain a mixed solution.

[0044] Among them: the mass-volume ratio of graphite oxide powder and sulfuric acid solution (mg / mL) is 1:0.25; the mass-volume ratio of graphite oxide powder and nitric acid solution (mg / mL) is 1:0.75.

[0045] ⑵ Add 8 times the volume of ultrapure water to the mixed solution, mix well, cool to room...

Embodiment 3

[0049] Example 3 Preparation of a water lubricant with graphene quantum dots as an additive. At room temperature, graphene quantum dots (GQDs) were added to ultrapure water to form an aqueous solution with a uniform and stable concentration of 8 mg / mL, namely Get water lubricant.

[0050] Among them: Graphene quantum dots are prepared according to the following method:

[0051] (1) After heating the graphite oxide powder at 300°C, disperse it in a sulfuric acid solution with a mass concentration of 96%. After sonicating at 30°C for 3.5 hours, add a 65% nitric acid solution with a mass concentration of nitric acid for 15 hours to obtain a mixed solution.

[0052] Among them: the mass-volume ratio (mg / mL) of graphite oxide powder and sulfuric acid solution is 1:0.3; the mass-volume ratio (mg / mL) of graphite oxide powder and nitric acid solution is 1:0.9.

[0053] (2) Add 10 times the volume of ultrapure water to the mixed solution, mix it and cool to room temperature, filter and wash wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com