System for implementing organic solid waste pyrolysis method and organic solid waste pyrolysis method

A technology of organic solid waste and pyrolysis, which is applied in special forms of dry distillation, petroleum industry, coke ovens, etc., can solve problems such as hidden safety hazards, increased operating costs, poor sealing effect, etc., to avoid extremely high operating costs and improve external performance. The effect of selling price and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

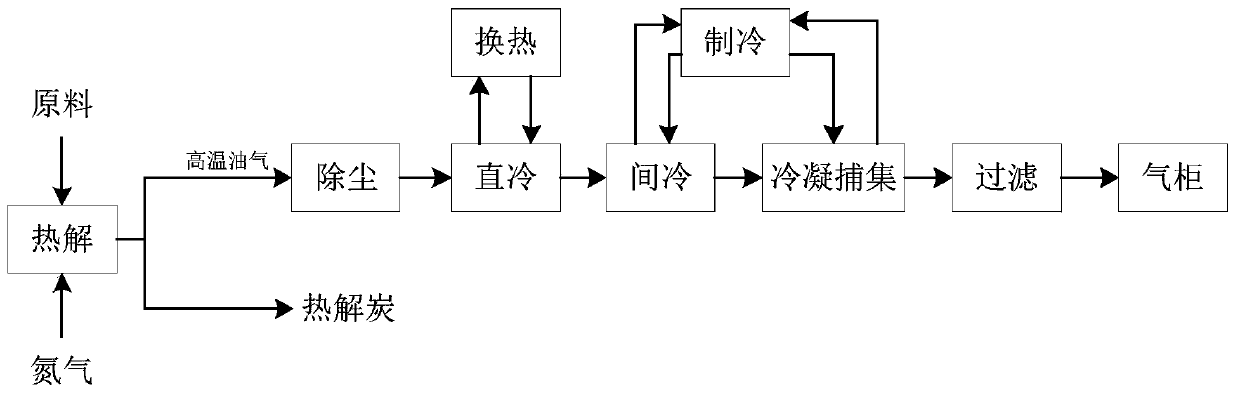

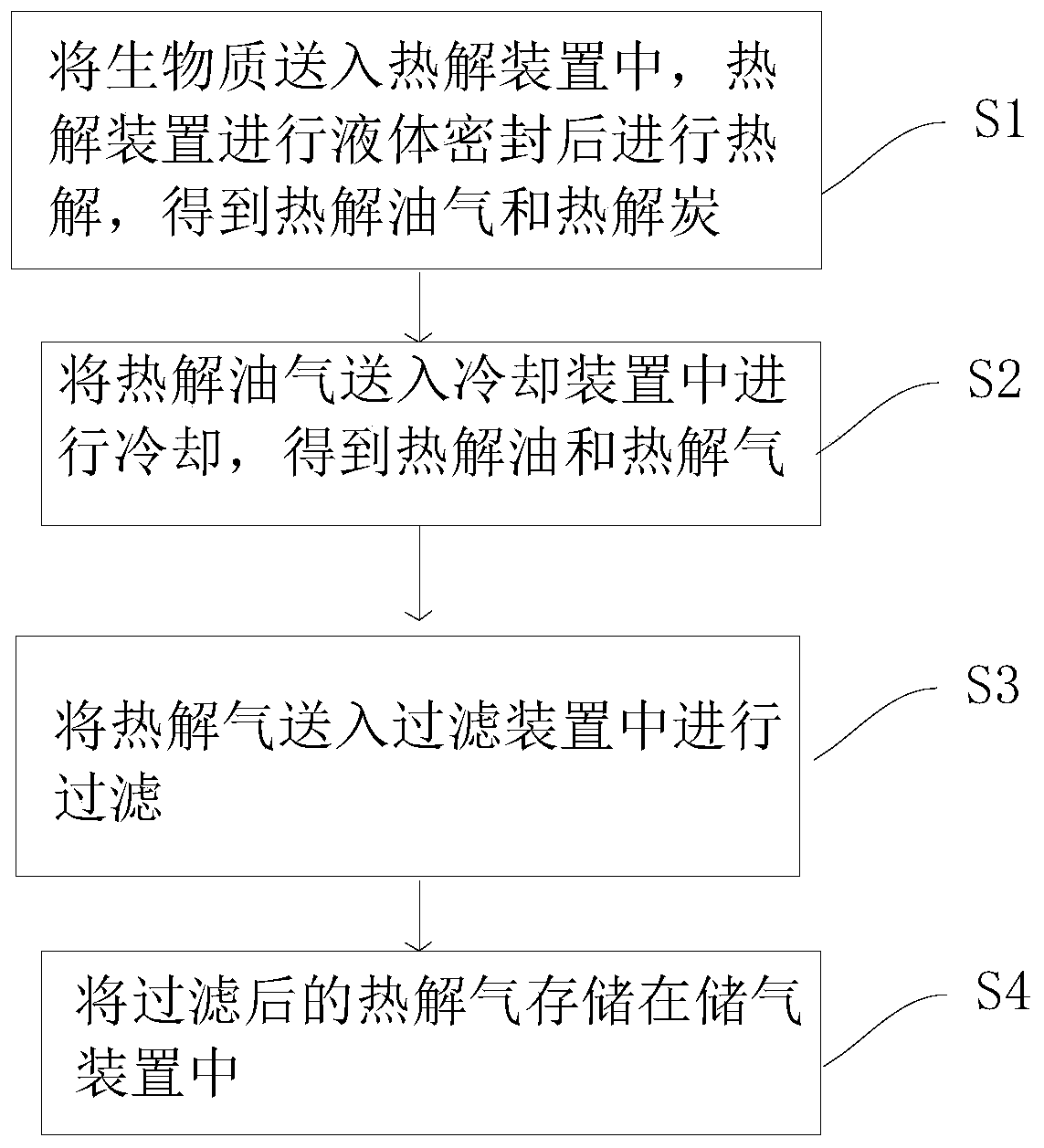

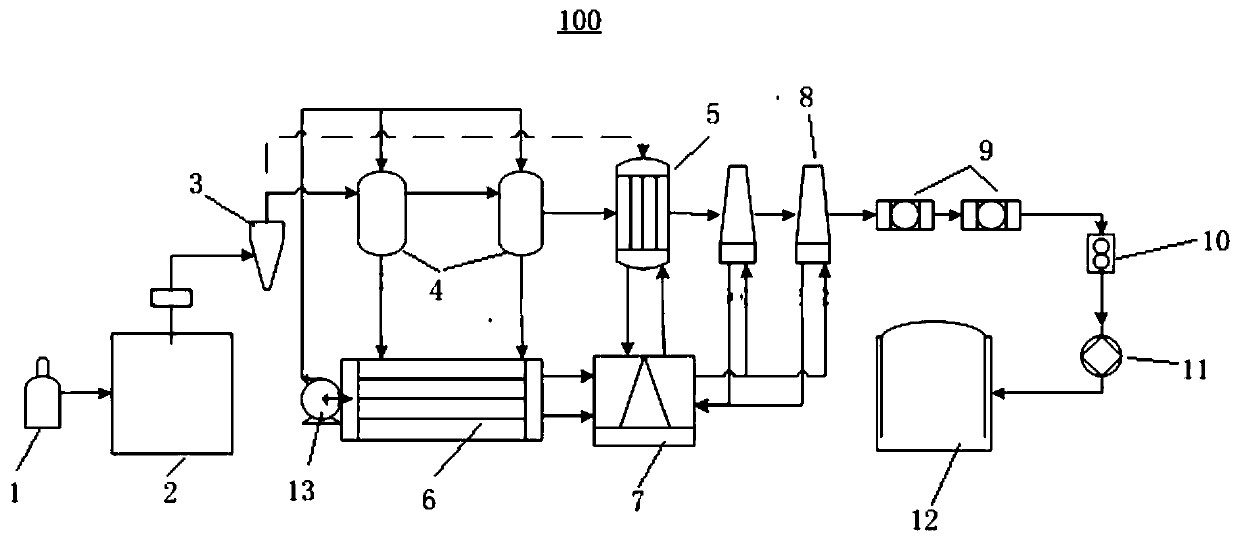

[0028] Refer below figure 1 and figure 2 A method for pyrolysis of organic solid waste according to an embodiment of the present invention is described.

[0029] Such as figure 1 As shown, the organic solid waste pyrolysis method according to the embodiment of the present invention may include the following steps: S1, sending the organic solid waste into the pyrolysis device 2, and the pyrolysis device 2 is liquid-sealed and then pyrolyzed to obtain pyrolysis oil gas and pyrolytic charcoal. The pyrolysis device 2 has no strict requirements on raw materials, and can handle raw materials of different shapes. The pyrolysis device 2 includes material frames 208, and different material frames 208 are selected for different raw materials. According to the characteristics of the material, when it is used to process granular materials with a particle size ≥ 1mm, the material frame 208 is a mesh material frame 208 with different apertures; when it is used to process powder materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com