Color candle clay with fragrance and production thereof

A candle and color technology, applied in the field of colored candle clay and its preparation, can solve the problems of high raw material cost, no color, smoke, etc., achieve the effect of reducing cost, improving grade and sales price, and reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] Take by weighing the raw materials (weight percent) according to the following proportions:

[0030] 1. Lotus scented white candle clay recipe

[0031] Refined Paraffin: 78%

[0032] Palmitic acid: 5%

[0033] Vaseline: 8%

[0034] Microcrystalline Wax: 8%

[0035] Lotus essence (candle essence): 1%

[0036] 2. Rose Scented Light Red Candle Clay Recipe

[0037] Refined Paraffin: 77%

[0038] Palmitic acid: 5.5%

[0039] Vaseline: 8%

[0040] Microcrystalline Wax: 8%

[0041] Rose essence (candle essence): 1.4%

[0042] Rose Red (Candle Dye): 0.1%

[0043] Other colors and fragrances of the present invention can be adjusted according to needs. Items in the formula can be adjusted by increasing or decreasing the ratio according to the actual use of the product.

[0044] The production method is as follows:

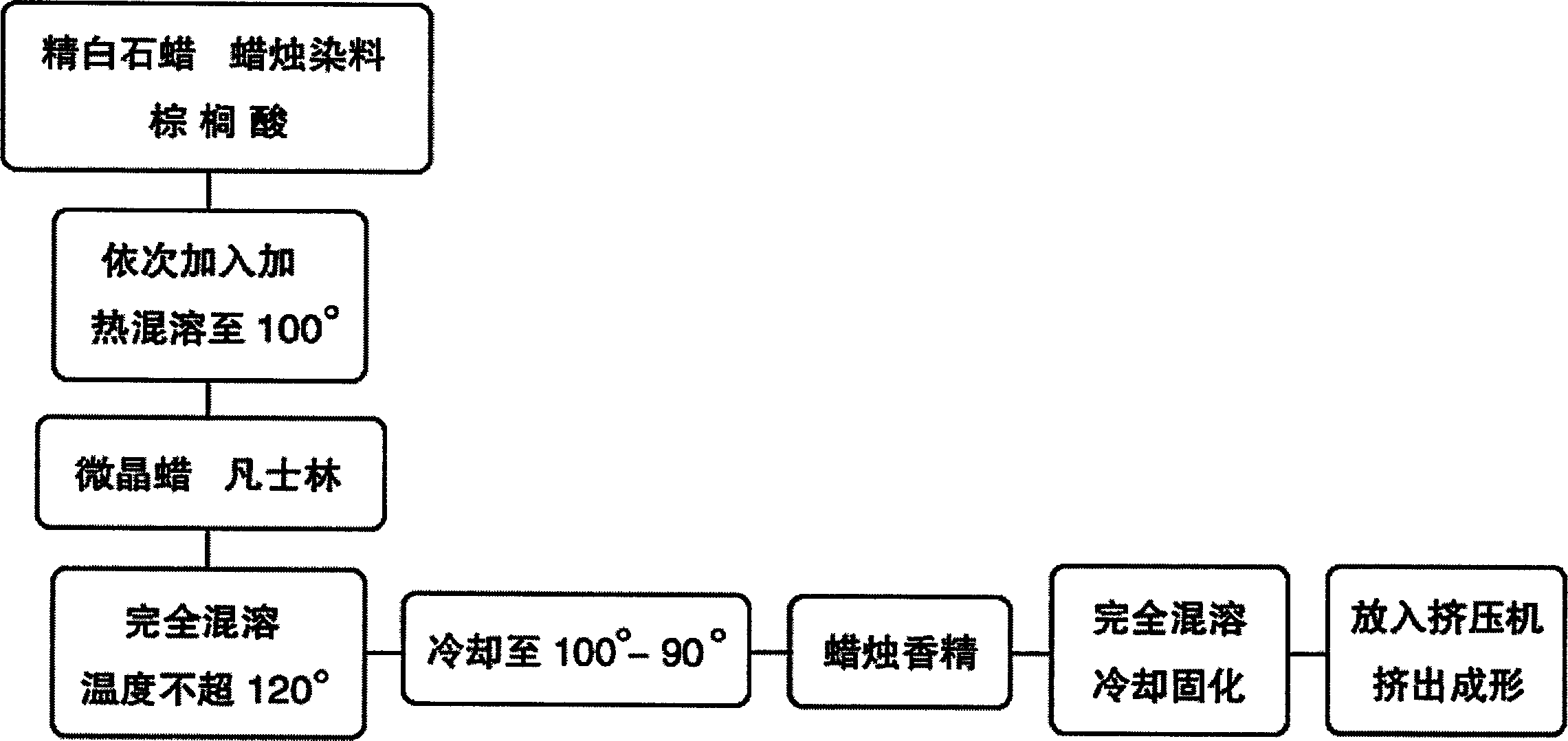

[0045] refer to figure 1 , Put the refined paraffin wax, candle dye, and palmitic acid into the pot and heat in turn, and when they are stirred and melt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com