Self-repairing antibacterial hydrogel based on borate bond

A technology of hydrogel and boric acid compound, applied in the field of materials, can solve problems such as environmental hazards, and achieve the effects of fast gel forming speed, mild gel forming conditions and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation of embodiment 1, PEG-Ugi

[0040] 1. Preparation of PEG-COOH

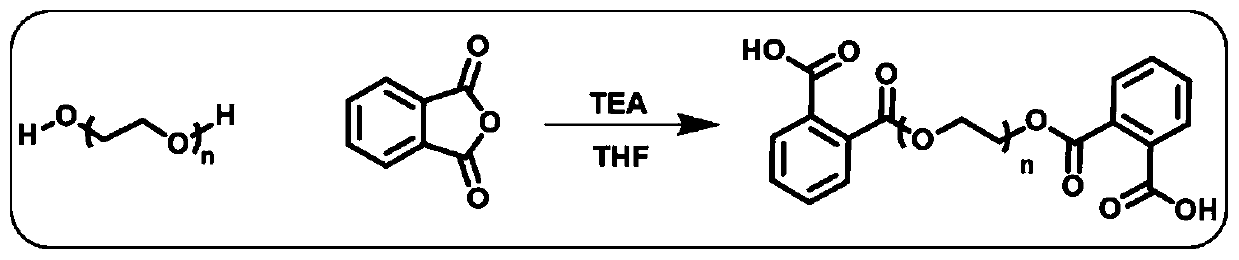

[0041] Synthetic route such as figure 1 shown.

[0042] The PEG3000 was dissolved in toluene and then the toluene was removed by rotary evaporation. This was repeated three times to remove the moisture in the PEG.

[0043] The above-mentioned anhydrous PEG was dissolved in ultra-dry tetrahydrofuran, and then two times the amount of phthalic anhydride and one equivalent of triethylamine were added. Connect a drying tube to the reaction bottle and react at room temperature for about 3 hours. The reaction solution was poured into diethyl ether to precipitate, and the white solid was collected by suction filtration. Dry the white solid in a vacuum desiccator until constant weight to obtain PEG-COOH.

[0044] 2. Preparation of PEG-Ugi

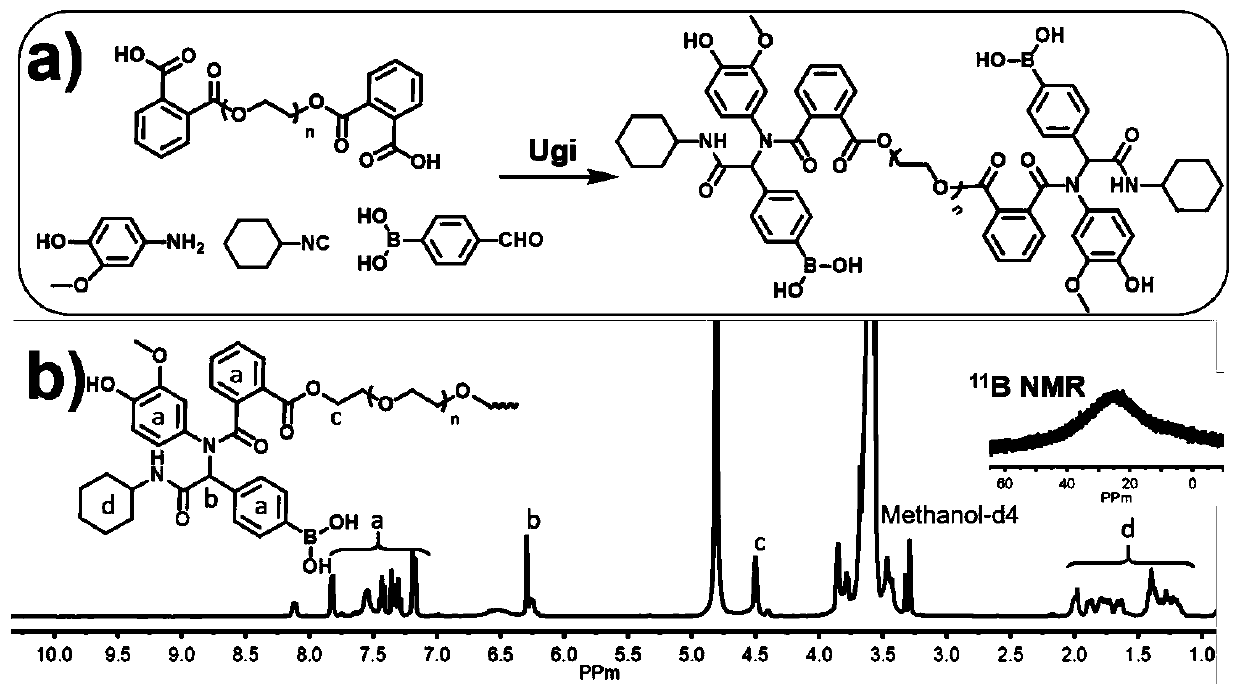

[0045] Synthetic roadmap as figure 2 a) as shown.

[0046] Dissolve PEG-COOH in methanol, then add 3 equivalents of 4-formylphenylboronic acid, 3 equivale...

Embodiment 2

[0048] Embodiment 2, the preparation of hydrogel

[0049] 1. Preparation of PVA solution

[0050] Heat the PBS solution (pH value is 7.4) to about 90° C., then add a certain amount of PVA powder, and stir overnight to obtain a PBS solution of PVA with a mass concentration of 8%.

[0051] 2. Preparation of PEG-Ugi solution

[0052] A certain amount of PEG-Ugi was added into the PBS solution, shaken to dissolve it completely, and a PBS solution of PEG-Ugi was obtained with a mass concentration of 8%.

[0053] 3. Preparation of hydrogel

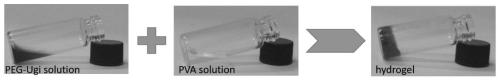

[0054] Take the PBS solution of PVA and the PBS solution of PEG-Ugi in the same volume, mix them quickly and violently for about 2-5 seconds, as image 3 shown. .

[0055] The concentration of PEG-Ugi in the PBS solution of PEG-Ugi was adjusted to 10% and 12% according to the above method to prepare hydrogels.

Embodiment 3

[0056] Embodiment 3, hydrogel property test

[0057] 1. Hydrogel strength test

[0058] Prepare a circular cake-shaped hydrogel sample (diameter ~ 20mm, room temperature ~ 25°C), put it on the lower plate test platform of the parallel plate after standing for about 1 hour, and trim its shape to match the test parallel plate. Data were collected under set conditions (shear modulus-frequency sweep test mode; strain 1%; frequency sweep range: 0.1 rad / s to 100 rad / s). The result is as Figure 4 As shown in a), as the solid content of PEG-Ugi increases, the gel strength of the hydrogel shows an increasing trend, indicating that the gel strength of the hydrogel is adjustable.

[0059] A small amount of hydrogel was taken, and its microstructure was observed by SEM after freeze-drying. Such as Figure 4 As shown in b), after the hydrogel loses water and collapses, pores can still be seen on the surface, indicating that the hydrogel has a network structure.

[0060] 2. Test of se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com