Surfactant, method for producing same, and solution containing same

A technology of surfactants and manufacturing methods, applied in the field of surfactants, can solve the problems of high cost of raw materials and energy, complicated reaction process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

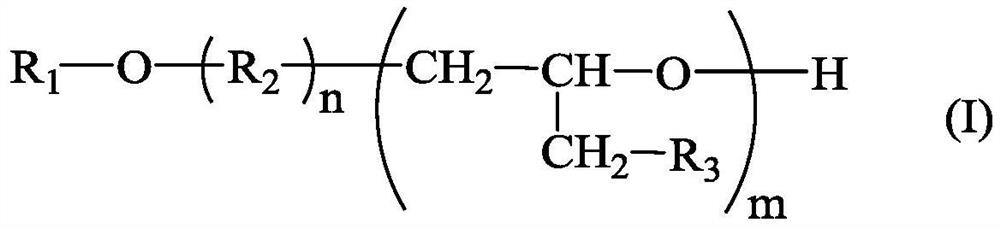

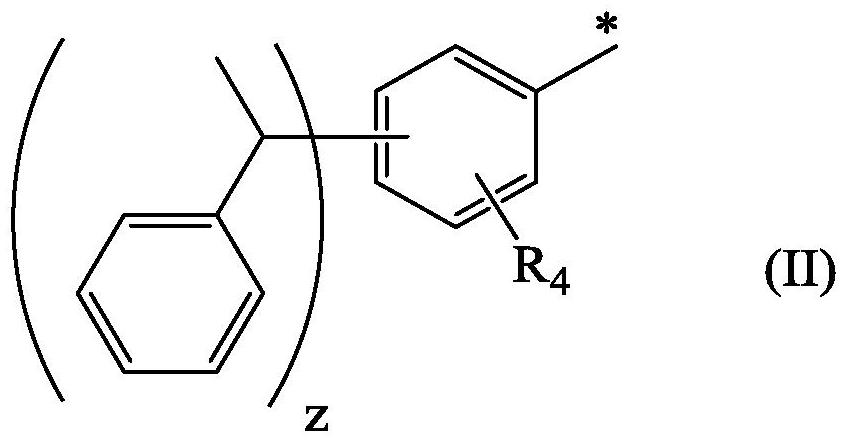

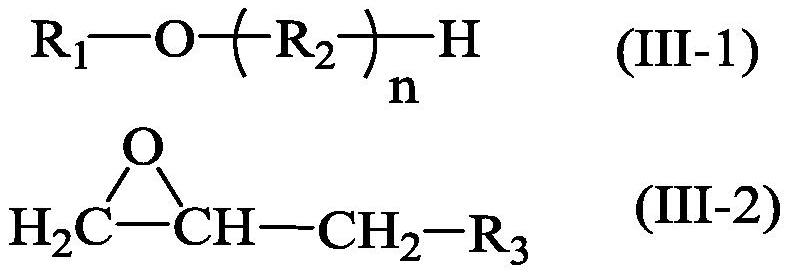

Method used

Image

Examples

Embodiment 1

[0068] First, 100 parts by weight of polyoxyethylene octyl phenyl ether and 2.6 parts by weight of potassium hydroxide were added to the reaction tank. Next, 29 parts by weight of butyl glycidyl ether was slowly dropped into the reaction tank. After the aforementioned mixture is uniformly mixed, the temperature of the reaction tank is set at 100° C. to 110° C. to perform a single-step reaction on the mixture. After the reaction is completed, the adsorbent and water are added, and the temperature of the reaction tank is heated to above 100°C for purification. After potassium hydroxide is removed, the product obtained is filtered to obtain the surfactant of Example 1 shown in the following formula (IV-1). The obtained surfactants were evaluated by the following evaluation methods of defoaming property, surface tension, wetting and penetrability and gelation evaluation, and the results of the evaluation items of defoaming property, surface tension and wetting and penetrating pro...

Embodiment 2

[0072] The preparation method of the surfactant of embodiment 2 to embodiment 6 is to use the same synthesis steps as the preparation method of the surfactant of embodiment 1, and the difference is that embodiment 2 to embodiment 6 is to change the kind of reactant and Usage amount, its formula and reaction condition are as shown in table 1. Wherein, the surfactants prepared in Example 2 to Example 6 have the structures shown in the following formulas (IV-2) to (IV-6) respectively. The obtained surfactants were evaluated by the following evaluation methods of defoaming property, surface tension and wettability, and the results are shown in Table 2-1. In addition, the surfactant prepared in Example 2 was further evaluated by the evaluation method of gelation evaluation, and the obtained results are shown in Table 2-2.

[0073]

[0074] In formula (IV-2), R 12 Represents an alkyl group with a carbon number of 9 to 11; n 2 represents 10; and m 2 represents 0.5.

[0075] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com