Preparation process of quick-change nozzle combined structure and machining mold thereof

A technology of combined structure and preparation process, which is applied in the field of water-packing ports, can solve problems such as unstable fixation, and achieve the effects of increasing resistance to molten steel scour, preventing leakage and preventing molten steel from seeping out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

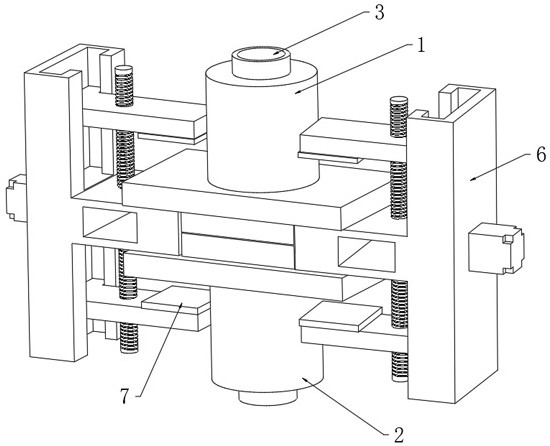

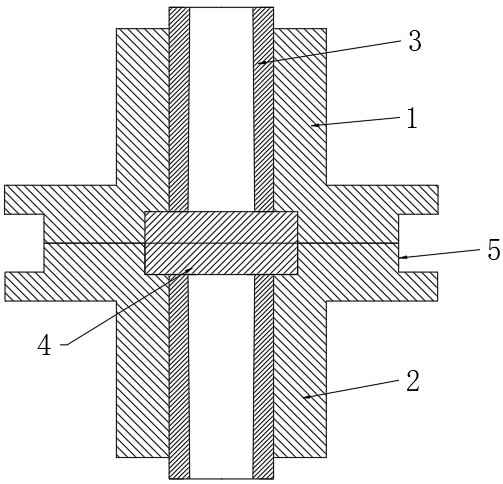

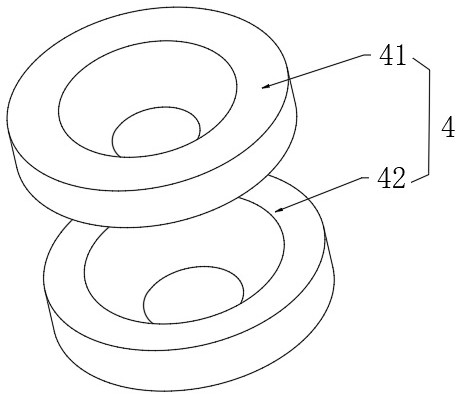

[0047] Such as Figure 1-Figure 5 As shown, a quick-change nozzle combination structure includes an upper nozzle 1 and a fixing device 6 .

[0048] The raw materials for the preparation of the upper nozzle and the lower nozzle include carbon-bonded light porous oxides, and the raw materials for carbon-bonded light porous oxides include aluminum oxide hollow spheres, calcium hexaaluminate and graphite. The raw materials for the preparation of the upper nozzle and the lower nozzle also include acidic substances, metal powder and additives. The acidic substance includes silicon dioxide or borax; the metal powder includes aluminum powder or magnesium powder, and the admixture includes bentonite, polyvinyl alcohol and methyl silicone oil.

[0049] Wherein, a lower nozzle 2 is provided below the upper nozzle 1, and a water guide pipe 3 is arranged inside the upper nozzle 1 and the lower nozzle 2, and the water guide pipe 3 is made of a high-temperature-resistant material for divert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com