Copolyester of furandicarboxylic acid and preparation method thereof

A technology of furandicarboxylic acid copolyester and dibasic acid, applied in the field of materials, can solve problems such as premature maturity, limited application scope, infant deformity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

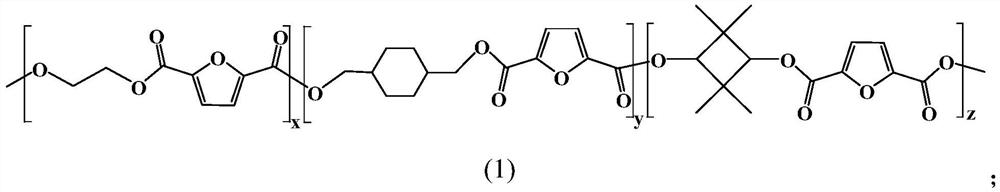

[0031] The preparation method of furandicarboxylic acid copolyester provided by the invention may further comprise the steps:

[0032] (1) Dibasic acid or its esterified product, dibasic alcohol and esterification reaction catalyst are mixed, carry out esterification reaction under inert atmosphere, obtain the first intermediate product; Wherein, described dibasic acid comprises furandicarboxylic acid, so The dihydric alcohols include ethylene glycol, 1,4-cyclohexanedimethanol and 2,2,4,4-tetramethyl-1,3-cyclobutanedimethanol;

[0033] (2) Under vacuum conditions, subjecting the first intermediate product to a precondensation reaction to obtain a second intermediate product;

[0034] (3) Under vacuum conditions, the second intermediate product is subjected to polycondensation reaction to obtain furandicarboxylic acid copolyester.

[0035] Specifically, the furandicarboxylic acid is 2,5-furandicarboxylic acid, and the 2,5-furandicarboxylate is dimethyl 2,5-furandicarboxylate. ...

Embodiment 1

[0058] Dimethyl 2,5-furandicarboxylate 46g, 1,4-cyclohexanedimethanol 12.6g, 2,2,4,4-tetramethyl-1,3-cyclobutanediol 28.8g and ethyl 7.0 g of diol was added to the polymerization reactor, and then 0.15% of anhydrous zinc acetate based on the molar amount of dimethyl 2,5-furandicarboxylate was added. Under an inert atmosphere, react at 180° C. for 4 hours to obtain the first intermediate product.

[0059] Add 0.2% antimony trioxide, 0.15% triphenyl phosphate and 0.1% antioxidant 1010 based on the molar weight of dimethyl 2,5-furandicarboxylate to the first intermediate product, at a vacuum degree of 500Pa ~3000Pa, 220°C pre-condensation for 0.5h to obtain the second intermediate product.

[0060] Then the second intermediate product was reacted at 240° C. for 3 hours under a vacuum of 200 Pa to obtain furandicarboxylic acid copolyester.

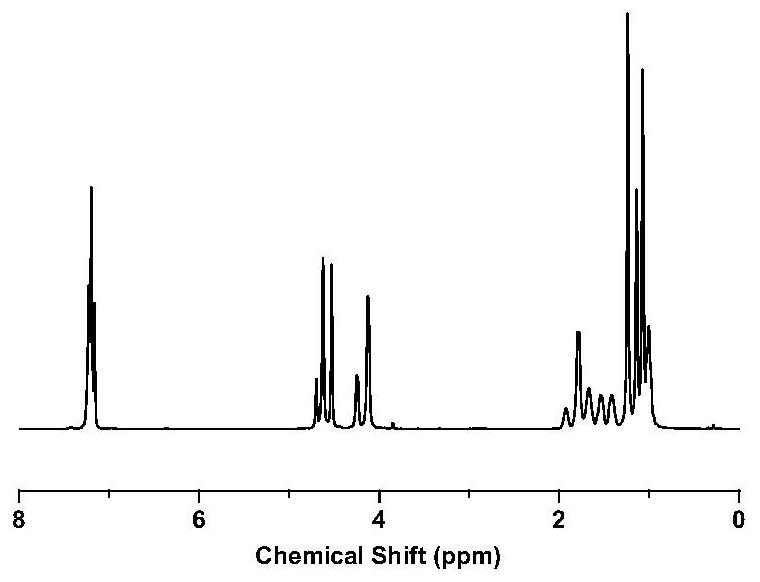

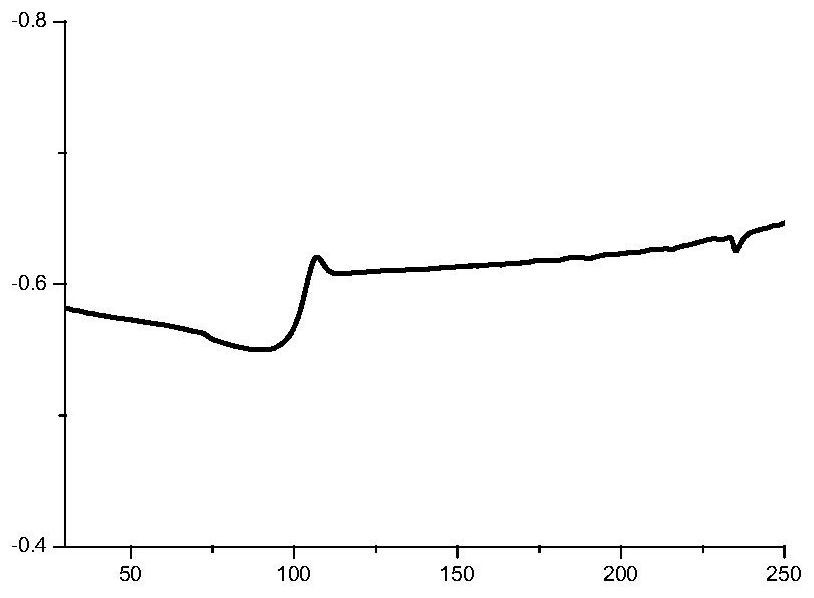

[0061] After testing, the relative number average molecular mass of the furandicarboxylic acid copolyester is 23000g / moL, the relative weig...

Embodiment 2

[0065] Dimethyl 2,5-furandicarboxylate 92.5g, 1,4-cyclohexanedimethanol 54.1g, 2,2,4,4-tetramethyl-1,3-cyclobutanediol 10.0g and 22.0 g of ethylene glycol was added to the polymerization reactor, and then 0.10% of anhydrous zinc acetate based on the molar amount of dimethyl 2,5-furandicarboxylate was added. Under an inert atmosphere, react at 160° C. for 2 h to obtain the first intermediate product.

[0066] Add 0.1% antimony trioxide, 0.25% triphenylphosphine and 0.5% antioxidant 168 based on the molar weight of dimethyl 2,5-furandicarboxylate to the first intermediate product, at a vacuum degree of 500Pa ~3000Pa, 230°C precondensation for 1.0h, to obtain the second intermediate product.

[0067] Then the second intermediate product was reacted at 250° C. for 4 hours under a vacuum of 200 Pa to obtain furandicarboxylic acid copolyester.

[0068] After testing, the relative number average molecular mass of the furandicarboxylic acid copolyester is 36000g / moL, the relative we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com