Low clearance single track tunnel contact wire positioning device

A tunnel contact and line positioning technology, which is applied in overhead lines, power lines, transportation and packaging, etc., can solve the problems of bow-shaped wrist arm deformation and inability to meet the requirements of line use, so as to increase reliability, strong field adaptability, and guarantee The effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

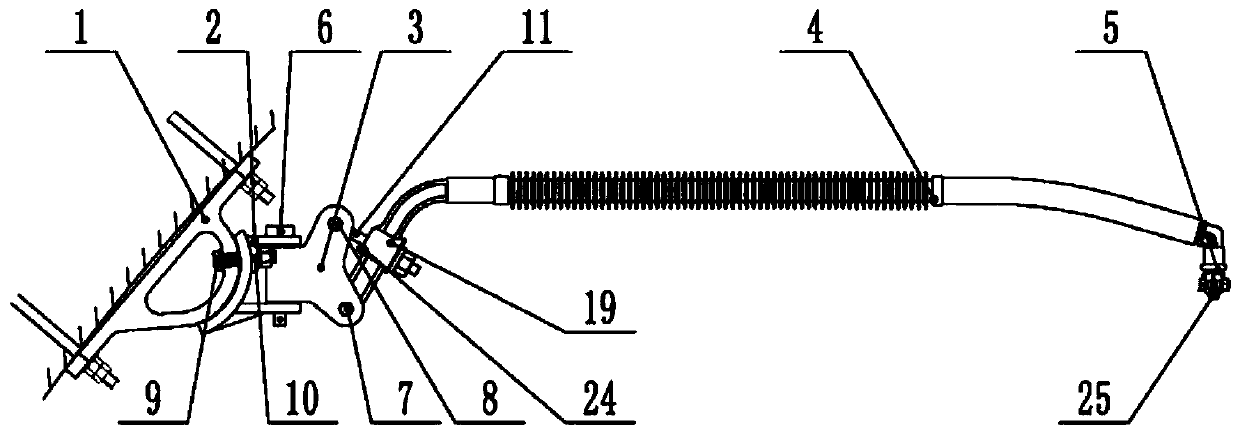

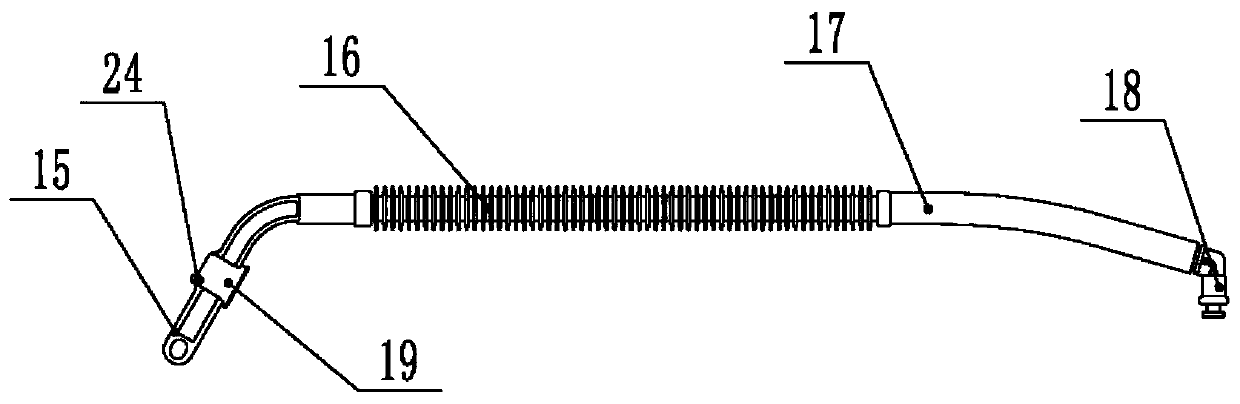

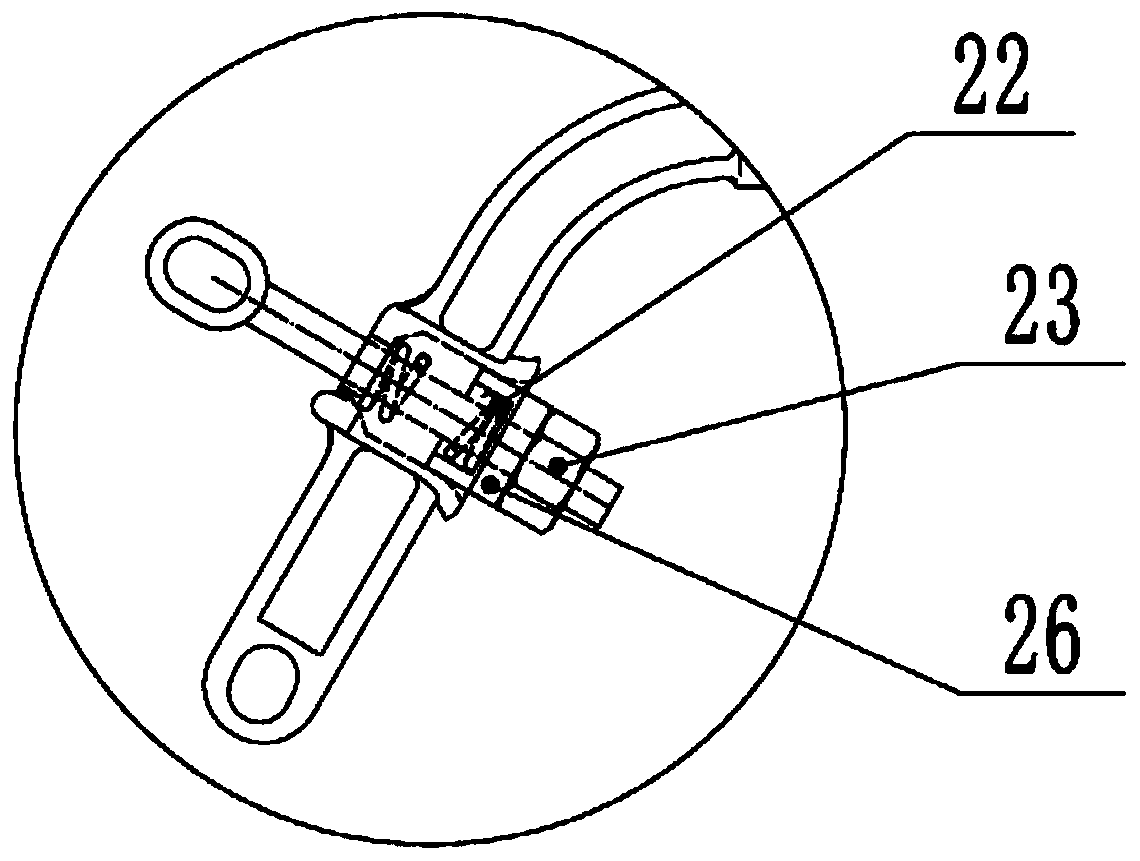

[0019] Attached below Figure 1-6 The present invention will be described in detail with specific embodiments.

[0020] A contact line positioning device for a low-headroom single-line tunnel, including an arcuate base 1, connecting ears 2, rotating ears 3, an elastic insulating limiter 4, and a positioning wire clamp 5; the arcuate base 1 is fixed in the tunnel by anchor bolts On the wall, and the front end of the bow-shaped base 1 is fixed with a connecting ear 2 through a bolt pair 9, and the front end of the connecting ear 2 is hinged with a rotating double ear 3 through a pin 6; the rear end of the elastic insulating limit locator 4 is a bending section , and the end of the bending section is hinged between the lower ears of the front end of the rotating double ear 3 through the bolt pin I7, the middle part of the bending section is equipped with an elastic pull rod 11, and the upper end of the elastic pull rod 11 is hinged at the front end of the rotating double ear 3 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com