Catalyst carrier, supported catalyst, preparation methods and applications of catalyst carrier and supported catalyst, and method for preparing hydrogen by methane steam reforming

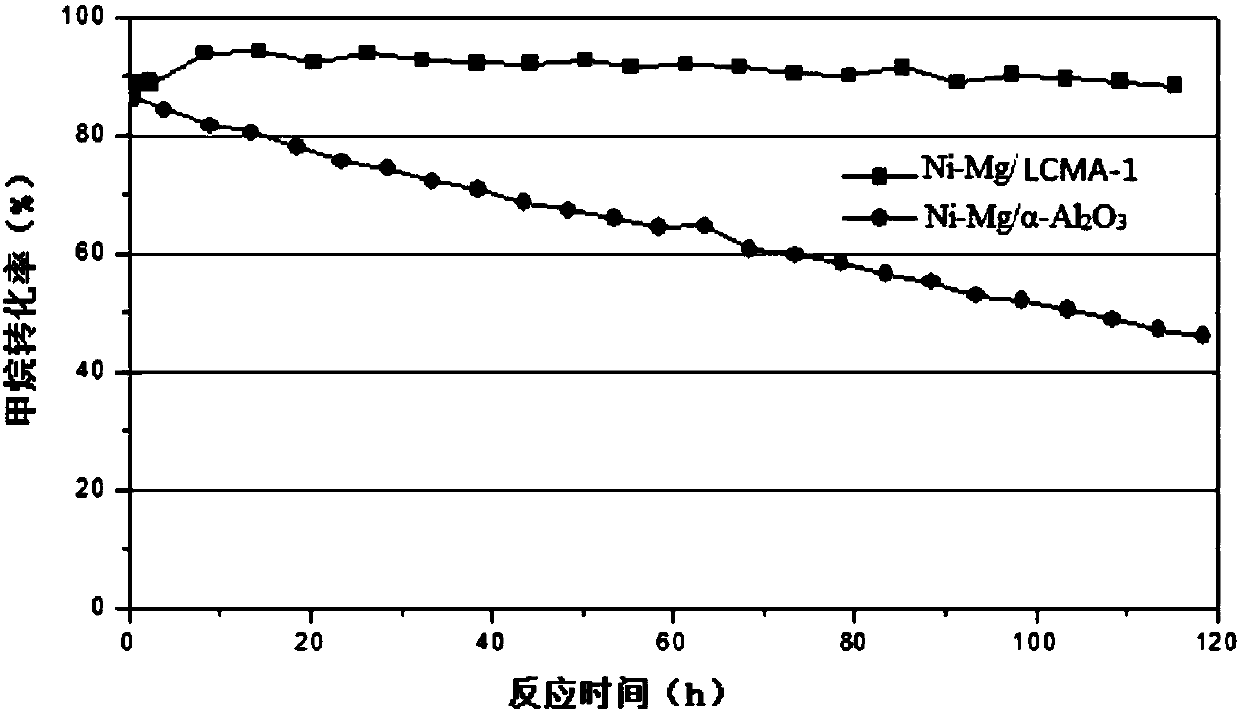

A supported catalyst and catalyst carrier technology, which is applied in the direction of catalyst activation/preparation, catalyst carrier, chemical instruments and methods, etc., can solve the problem of poor carbon deposition resistance of the catalyst, achieve high catalyst activity, inhibit the formation of carbon deposition, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0033] According to a preferred embodiment of the present invention, in the La modified alumina, La 2 o 3 The content is 0.1-6% by weight, preferably 0.5-3% by weight, more preferably 1.5-2.5% by weight.

[0034] The carrier that satisfies the aforementioned requirements of the present invention can realize the object of the present invention, and the present invention has no special requirements for its preparation method. For the present invention, the carrier described in the present invention is preferably prepared according to the following steps: the aluminum oxide containing La modified, CaCO 3 The mixture of , MgO, binder and pore-forming agent is ball-milled, then shaped and fired.

[0035] In the present invention, La-modified alumina, CaCO 3 , MgO, a binder and a pore-forming agent are ball-milled together, and then calcined to obtain a carrier with pores larger than 100 nm, and the pore volume of the pores larger than 100 nm accounts for 75-95% of the total pore...

Embodiment 1

[0097] (1) Preparation of La-modified alumina

[0098] 11.4g of La(NO 3 ) 2 9H 2 O was dissolved in 210mL of deionized water and stirred to dissolve, and 300g of pseudoboehmite was impregnated with it as the impregnating solution. After standing for 2 hours, the water was evaporated to dryness, and then calcined at 1200°C for 2 hours to obtain La-Al 2 o 3 -1. Among them, the content of La is 2% by weight, and the specific surface area is 71.4m 2 / g, the pore volume is 0.212cm 3 / g.

[0099] (2) Preparation of catalyst carrier

[0100] Weigh 130g of La-Al 2 o 3 -1, 30g of MgO, 18g of CaCO 3 , 1.05g magnesium stearate, 0.4g charcoal powder and 6mL carboxymethyl cellulose were mixed and ball milled for 20 hours to 100 mesh-150 mesh. Put the compressed pellet (diameter 1cm, thickness 3mm) into a muffle furnace and bake at 1200°C for 5 hours at a high temperature to obtain a catalyst carrier. The obtained support is denoted as LAMC-1, wherein the content of La modified ...

Embodiment 2

[0115] (1) Preparation of La-modified alumina

[0116] 8.4g of La(NO 3 ) 2 9H 2 O was dissolved in 210mL of deionized water and stirred to dissolve, and 300g of pseudo-boehmite was impregnated with it as the impregnating solution. After standing for 2 hours, the water was evaporated to dryness, and then calcined at 1300°C for 1 hour to obtain La-Al 2 o 3 -2. Among them, the content of La is 1.5% by weight, and the specific surface area is 64.5m 2 / g, the pore volume is 0.203cm 3 / g.

[0117] (2) Preparation of catalyst carrier

[0118] Weigh 120g of La-Al 2 o 3 -2, 28g of MgO, 22g of CaCO 3 , 1.05g magnesium stearate, 0.4g charcoal powder and 6mL carboxymethyl cellulose were mixed and ball-milled for 30 hours to below 100 mesh-150 mesh, and then poured into a mold for tableting after mixing and ball-milling evenly. The tablet molding pressure was 15MPa, and then Then put the compressed pellet (diameter 1cm, thickness 3mm) into a muffle furnace and bake at 1300°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com