Tobacco additive and application thereof

A tobacco additive and tobacco technology, which is applied in the field of tobacco, can solve the problems of affecting the flavor of cigarettes and the loss of cigarette flavor, and achieve the effect of large-scale application and promotion, reducing miscellaneous gas and irritation, and improving oral comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

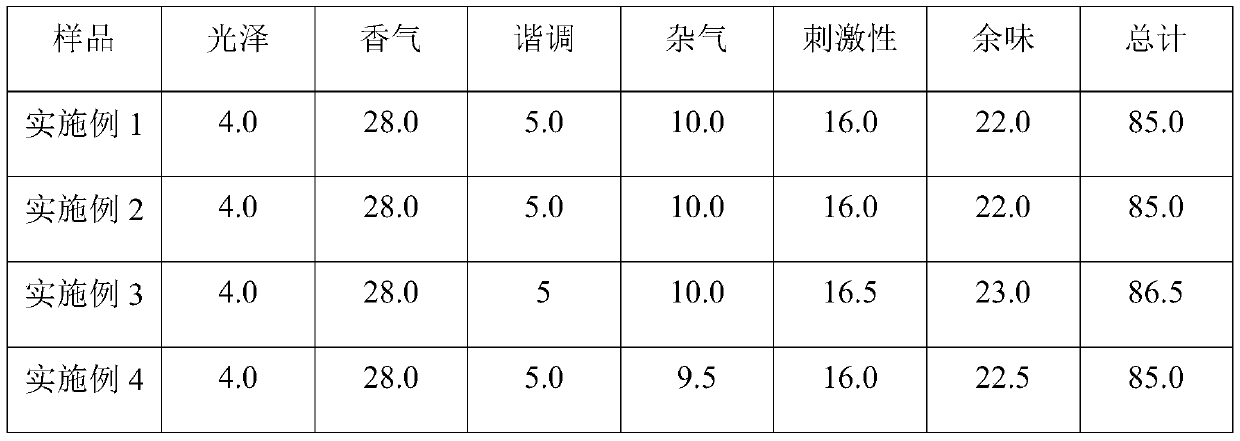

Examples

Embodiment 1

[0050] (1) Take 20g of squalene and place it in a completely dry container, then add 0.2g of organic acid and 0.5 part of tobacco flavoring agent, and add 50g of ethyl acetate while stirring until fully mixed to obtain a tobacco additive.

[0051] (2) Weigh 1g of the tobacco additive prepared in step (1), and then use a sprayer to evenly spray the tobacco additive on the surface of 100g shredded tobacco; then place the shredded tobacco at a temperature of 25±2°C and a relative humidity of 60±2 % in a constant temperature and humidity box for 4 hours, and finally roll the balanced shredded tobacco into cigarettes with a factory cigarette rolling machine.

[0052] Above-mentioned organic acid is the malic acid-ethanol solution that mass concentration is 5%;

[0053] The above-mentioned tobacco additive is an ethyl maltol-ethanol solution with a mass concentration of 0.5%.

Embodiment 2

[0055] (1) Weigh 25g of squalene and place it in a completely dry container, then add 0.3g of organic acid and 0.5 part of tobacco flavoring agent, and then add 57.5g of caprylic acid glycerides while stirring until completely mixed to obtain tobacco With additives.

[0056] (2) Weigh 1g of the tobacco additive prepared in step (1), and then use a sprayer to evenly spray the tobacco additive on the surface of 100g shredded tobacco; then place the shredded tobacco at a temperature of 25±2°C and a relative humidity of 60±2 % in a constant temperature and humidity box for 4 hours, and finally roll the balanced shredded tobacco into cigarettes with a factory cigarette rolling machine.

[0057] Above-mentioned organic acid is the malic acid-ethanol solution that mass concentration is 5%;

[0058] The above-mentioned tobacco additive is an ethyl maltol-ethanol solution with a mass concentration of 0.5%.

Embodiment 3

[0060] (1) Weigh 30g squalene and place it in a completely dry container, then add 0.5g organic acid and 1.0 part of tobacco flavoring agent, and add 68.5g caprylic acid glyceride while stirring until completely mixed evenly to obtain tobacco With additives.

[0061] (2) Weigh 1g of the tobacco additive prepared in step (1), and then use a sprayer to evenly spray the tobacco additive on the surface of 100g shredded tobacco; then place the shredded tobacco at a temperature of 25±2°C and a relative humidity of 60±2 % in a constant temperature and humidity box for 4 hours, and finally roll the balanced shredded tobacco into cigarettes with a factory cigarette rolling machine.

[0062] Above-mentioned organic acid is the malic acid-ethanol solution that mass concentration is 5%;

[0063] The above-mentioned tobacco additive is an ethyl maltol-ethanol solution with a mass concentration of 0.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com