A manufacturing process of a P-band low-noise amplifier

A technology of low-noise amplifier and manufacturing process, applied in amplifiers, improved amplifiers to reduce noise impact, amplifiers with semiconductor devices/discharge tubes, etc., can solve the problem that the production and manufacturing process does not have mature technical solutions, affect technology promotion and application, etc. problems, to achieve the effect of scientific manufacturing process, high gain, and high product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

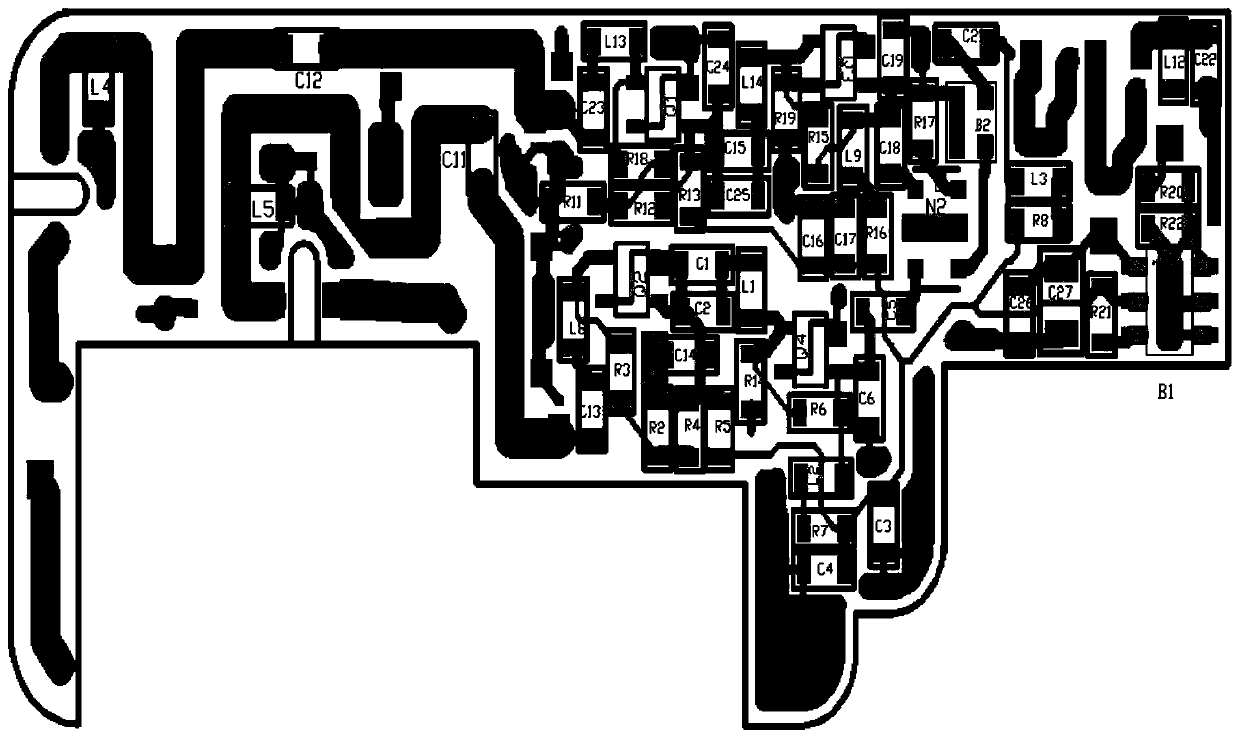

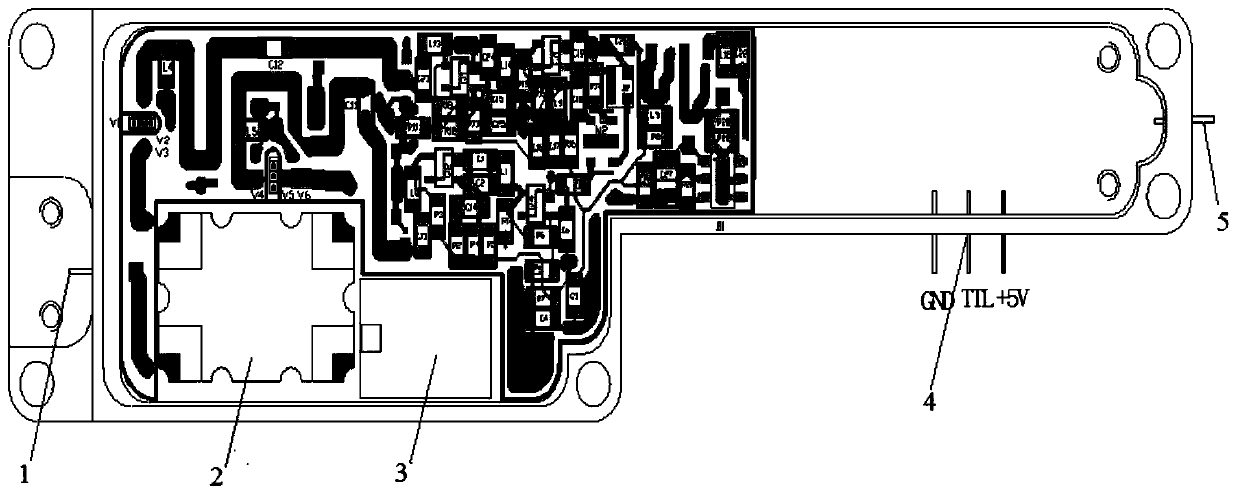

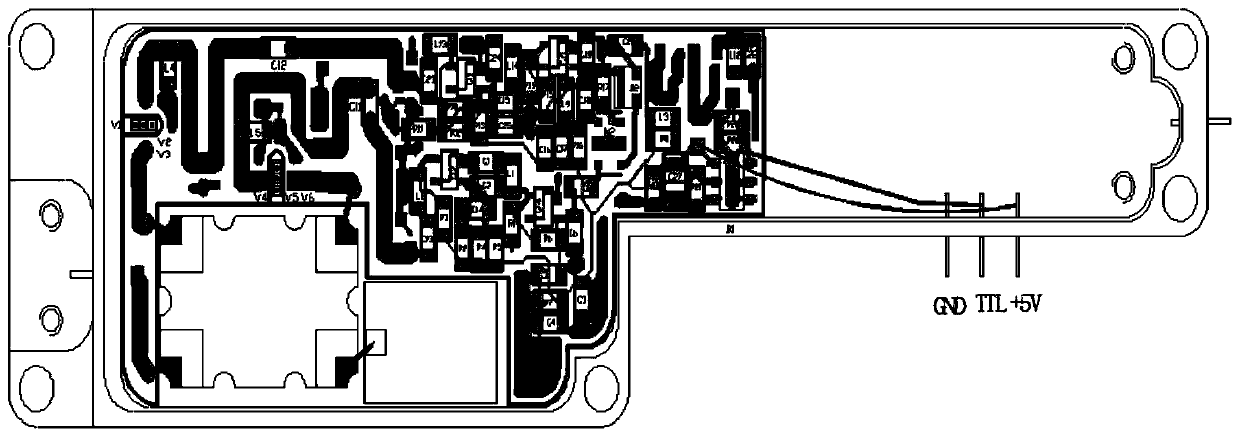

[0026] The specific implementation of the present invention will be further described in detail by describing the embodiments below with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

[0027] like figure 1 The structure of the present invention shown is a P-band low noise amplifier. The present invention is the manufacturing process of the P-band low-noise amplifier. In order to realize the invention purpose of the manufacturing process of P wave band low noise amplifier, the technical scheme that the present invention takes is:

[0028] like Figure 1 to Figure 6 As shown, the process of the manufacturing process mainly includes:

[0029] Step 1. Sinter the components onto the circuit board:

[0030] 1.1. Turn on the dispensing machine and adopt the continuous dispensing mode. The pressure of the dispensing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com