Nano sponge carbon composite Cu2O and Cu flexible electrode material and preparation method thereof

A flexible electrode and nano-sponge technology, which is applied in hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, battery electrodes, etc., can solve the problem of the combination of active materials and current collectors affecting the stability of electrode functions and affecting the electrochemical performance of materials, etc. problem, achieve good interface integrity, eliminate adverse effects, and achieve high specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

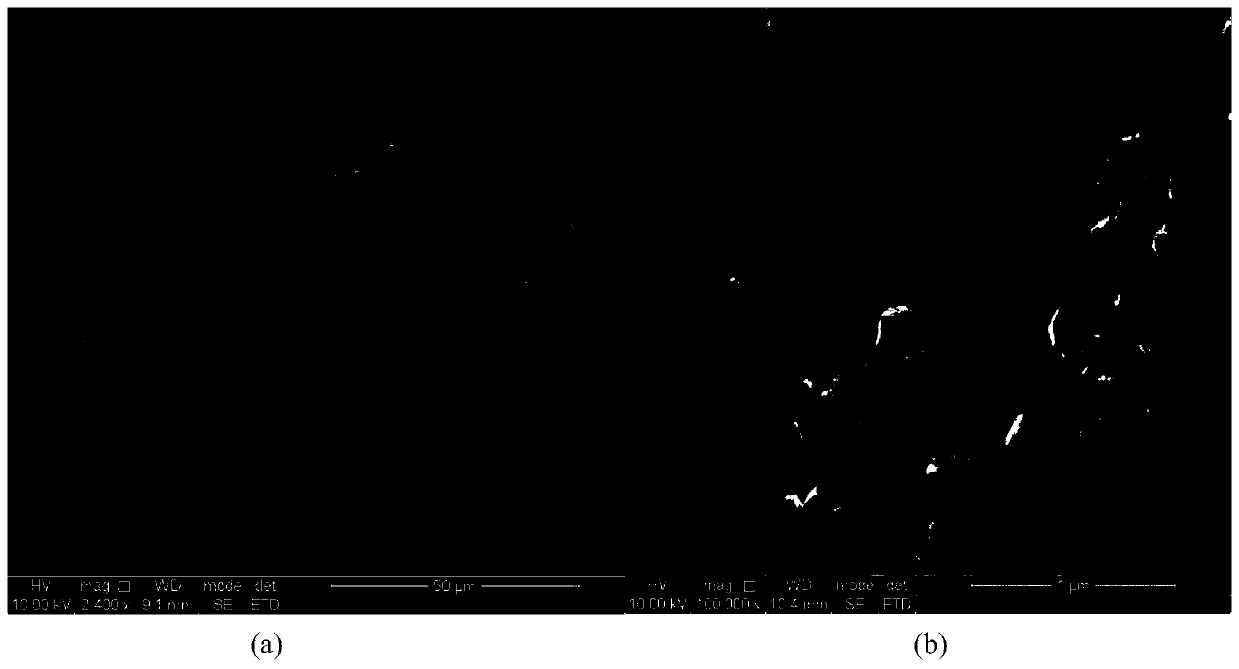

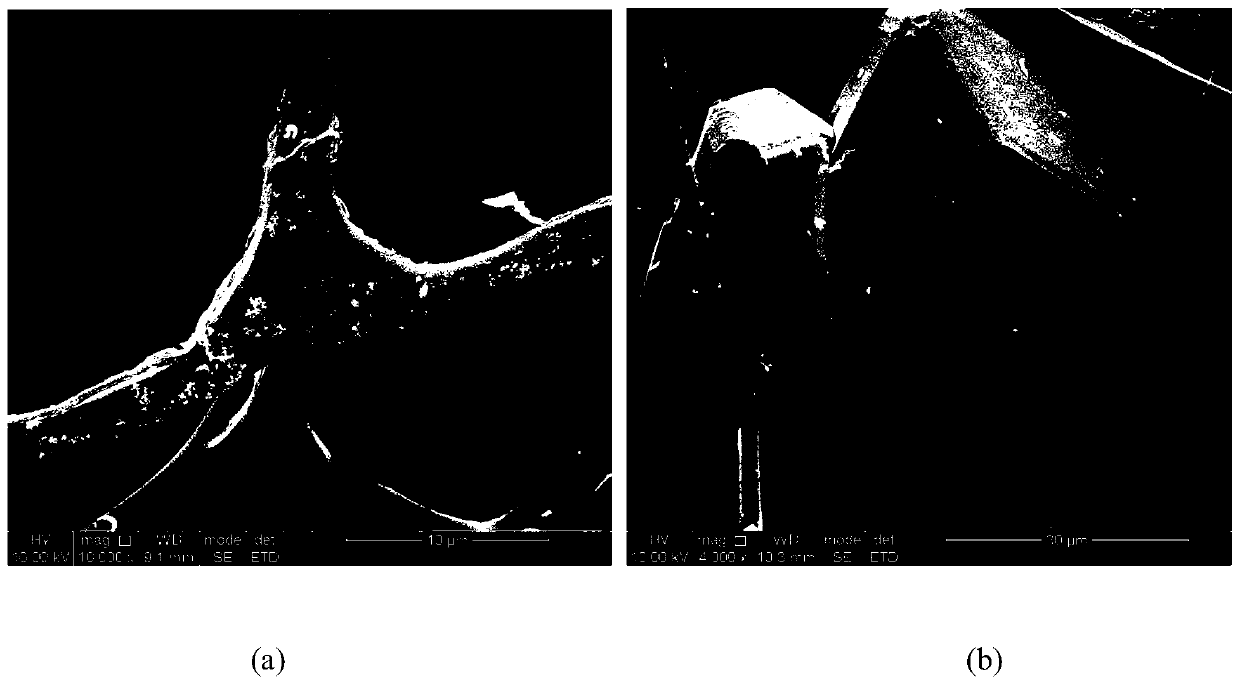

[0035] This embodiment improves a method for preparing a nano-sponge carbon composite CuO and Cu flexible electrode material, which specifically includes the following steps:

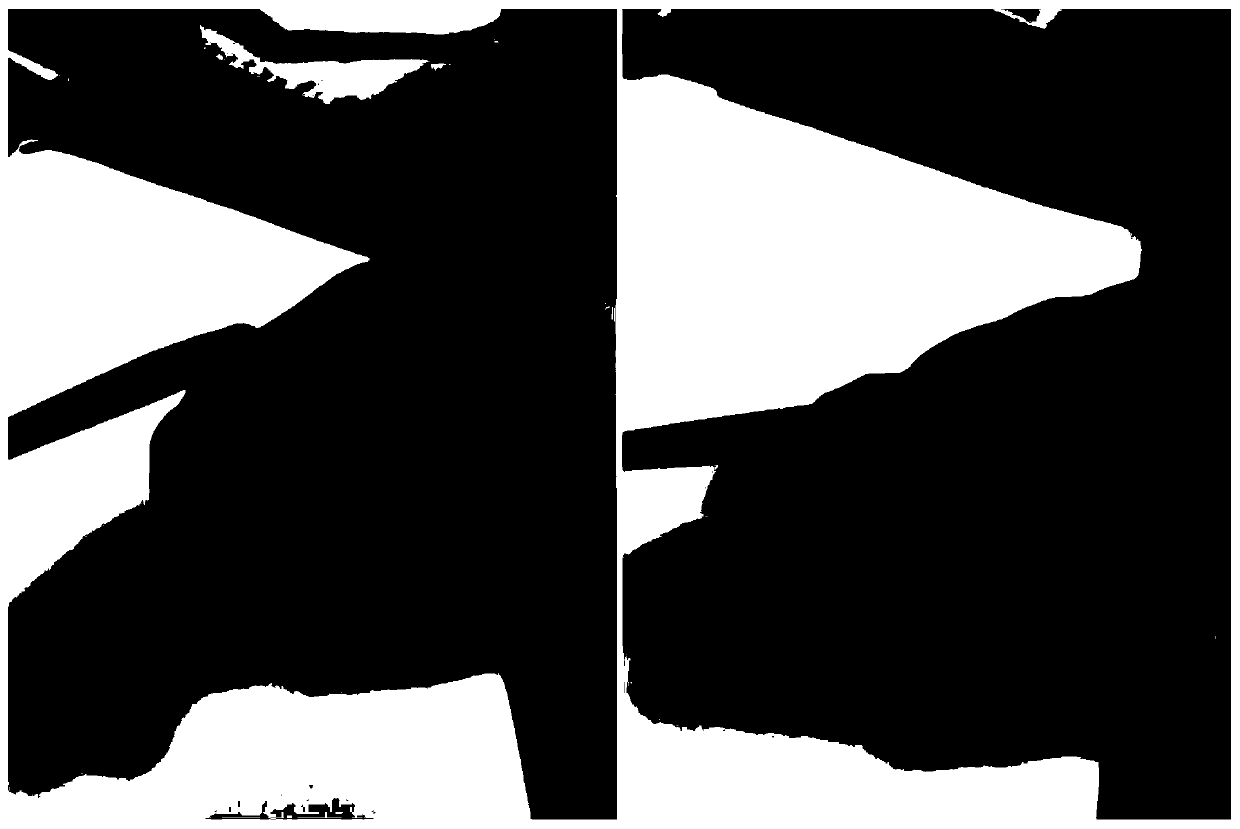

[0036] (1) A melamine nano-sponge whose size is 10×10×30 cm is carbonized at 500° C. for 3 hours under an argon atmosphere to obtain a flexible porous carbon material for subsequent use;

[0037] (2) Soak the flexible porous carbon material prepared in step (1) in a mixed acid solution formed by concentrated nitric acid and concentrated sulfuric acid at 80°C for 2 hours for surface hydroxylation treatment. In the mixed acid solution, concentrated nitric acid and concentrated The volume ratio of sulfuric acid is 3:1, and then the surface hydroxylated flexible porous carbon material is cleaned and dried for future use.

[0038] (3) Dissolve 3.0 g of copper acetate in 50 ml of deionized water, adjust the pH to 7, and sonicate in an ice bath for 30 minutes to obtain a copper precursor solution for later use...

Embodiment 2

[0042] The steps of this example are basically the same as those of Example 1, except that the hydrothermal reaction temperature in Step 5 is changed to 220° C., and the time is changed to 18 hours.

Embodiment 3

[0044] The steps of the present embodiment and embodiment 1 are basically the same, except that the copper source in step 3 is changed to copper chloride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com