Laser repairing method of damaged roller

A technology of laser repairing and rolling, applied in laser welding equipment, coating, metal material coating process, etc., can solve the problem of low bonding strength, and achieve the effect of reducing cost, enhancing bonding strength and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

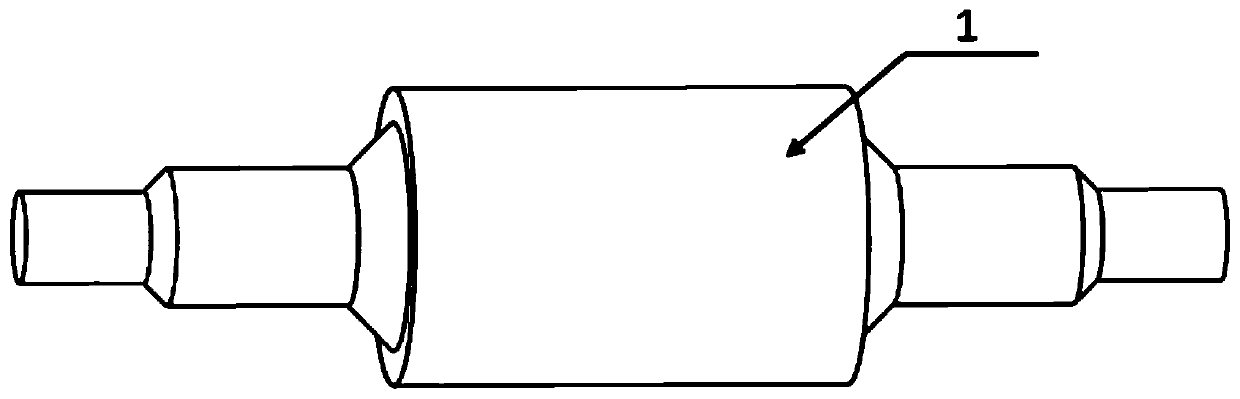

[0031] Such as figure 1 Shown is the roll to be repaired or to be remanufactured, and the specific process steps of the laser repair method for the roll to be repaired or to be remanufactured are as follows:

[0032] (1) Roll surface pretreatment: remove the wear and failure layer on the surface of roll 1, and then turn and grind to achieve the same shape as the finished roll body;

[0033] (2) Measure the size of the roll after pretreatment: roll 1 perimeter and width;

[0034] (3) choose a piece of 80CrN13W steel plate 2, its length and width are equal to the width and the circumference of roll 1 respectively, and the thickness of steel plate 2 is 2mm (such as figure 2 shown);

[0035] (4) Under the protection environment of transporting inert gas, use laser cladding to clad a layer of high hardness and wear-resistant mixed material with a thickness of 0.2 mm on the surface of the above-mentioned 80CrN13W steel plate 2 to form an alloy powder layer 3. The wear-resistant m...

Embodiment 2

[0040] The specific process steps of the laser repair method for the roll to be repaired or to be remanufactured are as follows:

[0041] (1) Roll surface pretreatment: remove the wear and failure layer on the surface of roll 1, and then turn and grind to achieve the same shape as the finished roll body;

[0042] (2) Measure the size of the roll after pretreatment: roll 1 perimeter and width;

[0043] (3) choose a piece of high chromium cast steel plate 2, its length and width are equal to the width and the circumference of roll 1 respectively, and the thickness of steel plate 2 is 4mm;

[0044] (4) Under the protection environment of transporting inert gas, use laser cladding to clad a layer of high hardness and wear-resistant mixed material with a thickness of 0.4 mm on the surface of the above-mentioned high-chromium cast steel plate 2 to form an alloy powder layer 3. The wear-resistant mixed material It is a 5:5 mixed powder of nickel-based alloy and tungsten carbide, whe...

Embodiment 3

[0049] The specific process steps of the laser repair method for the roll to be repaired or to be remanufactured are as follows:

[0050] (1) Roll surface pretreatment: remove the wear and failure layer on the surface of roll 1, and then turn and grind to achieve the same shape as the finished roll body;

[0051] (2) Measure the size of the roll after pretreatment: roll 1 perimeter and width;

[0052] (3) choose a piece of 8CrMoV steel plate 2, its length and width are equal to the width and the circumference of roll 1 respectively, and the thickness of steel plate 2 is 3mm;

[0053] (4) Under the protection environment of transporting inert gas, use laser cladding to clad a layer of high-hardness wear-resistant mixed material with a thickness of 0.1 mm on the surface of the above-mentioned high-chromium cast steel plate 2 to form an alloy powder layer 3. The wear-resistant mixed material It is a 5:5 mixed powder of nickel-based alloy and tungsten carbide, wherein the nickel-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com