A cesium iodide scintillator co-doped with indium and thallium and its application

A cesium iodide scintillator and cesium iodide technology, applied in chemical instruments and methods, vacuum evaporation plating, coating, etc., to achieve high stability, improved stability, and high scintillation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: preparation (Cs 0.9985 Tl 0.001 In 0.0005 ) I 1.001 film

[0023] 259.42CsI, 0.331g TlI and 0.248g InI 3 After fully mixing, put it into a molybdenum metal evaporation boat fixed on the electrode, heat the single crystal silicon wafer to 180°C by means of resistance heating, and adjust the pressure in the steam chamber to 10 -3 torr, with Evaporate at a certain evaporation rate. During evaporation, the substrate frame rotates to ensure the uniformity of the film. When the thickness of the film reaches 80 μm, stop the evaporation. After the temperature drops to 150°C, keep it warm for 30 minutes for annealing, cool naturally to room temperature, and grow the obtained film. The sample is colorless and transparent, and is firmly combined with the monocrystalline silicon wafer, which can also be replaced by an aluminum wafer or a ceramic wafer.

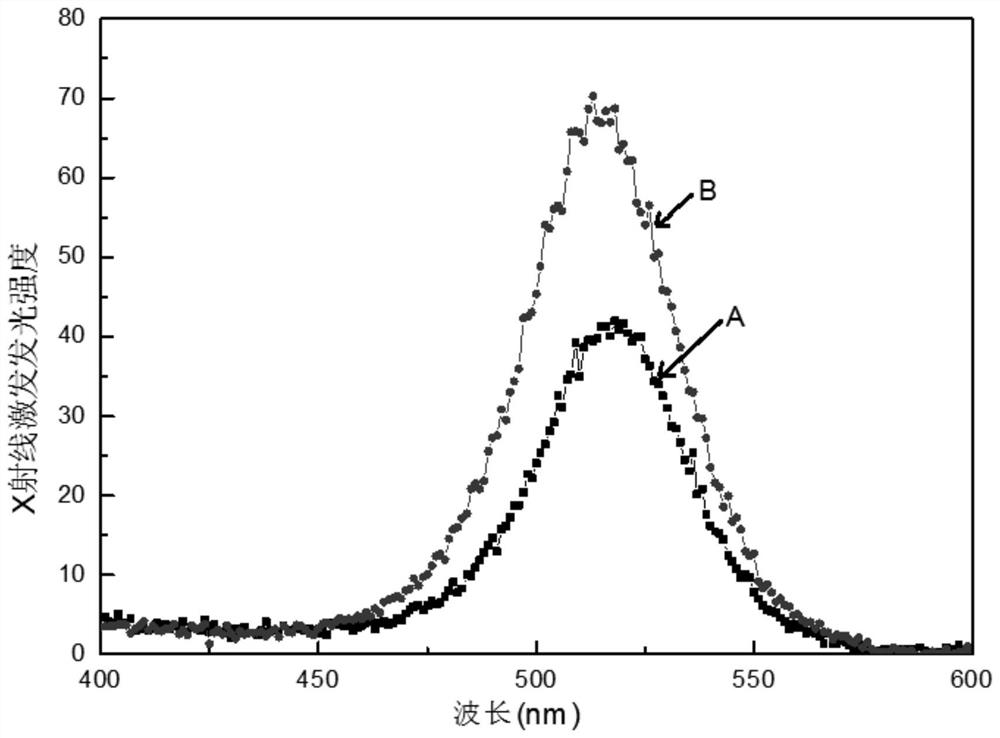

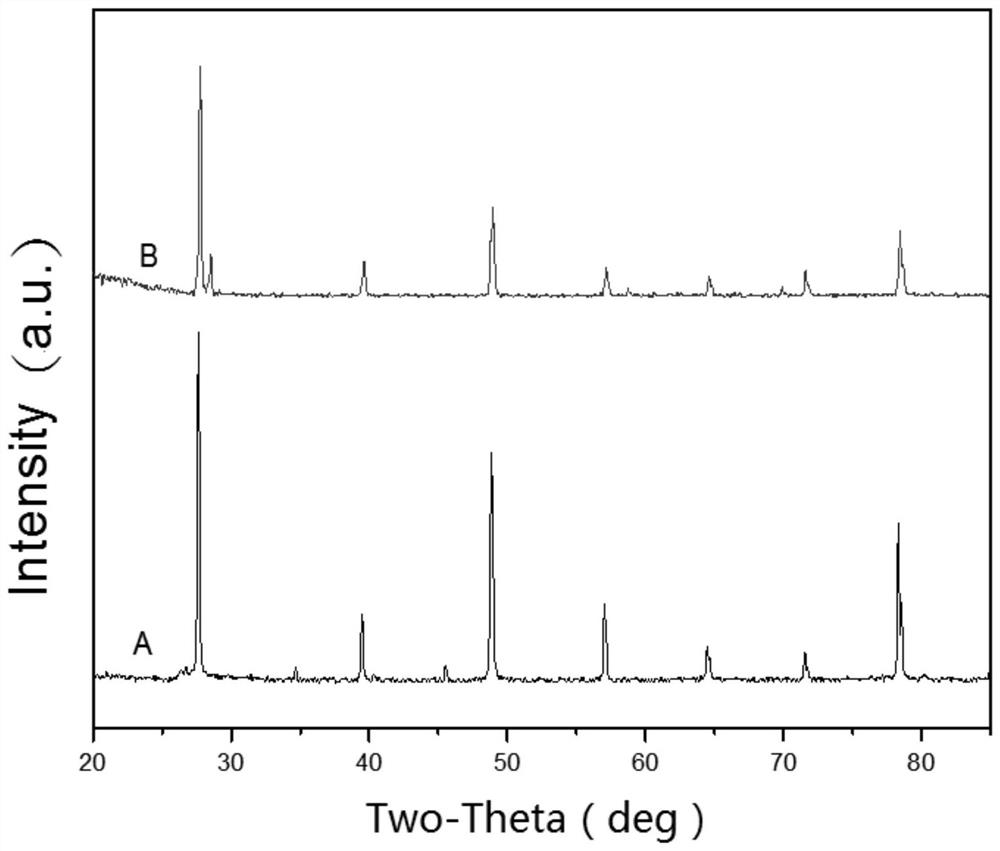

[0024] The film samples prepared in Comparative Example and Example 1 were respectively subjected to X-ray e...

Embodiment 2

[0027] Embodiment 2: preparation (Cs 0.998 Tl 0.001 In 0.001 ) I 1.002 film

[0028] 259.30g CsI, 0.331g TlI and 0.496g InI 3 After mixing well and evenly, put it into a molybdenum metal evaporation boat fixed on the electrode, heat the glass sheet to 250°C by means of resistance heating, and adjust the pressure in the steam chamber to 10 - 5 torr, with Evaporate at a certain evaporation rate. During evaporation, the substrate holder rotates to ensure the uniformity of the film. When the thickness of the film reaches 600 μm, stop the evaporation. After the temperature drops to 350°C, keep it warm for 90 minutes and anneal, cool naturally to room temperature, and grow the obtained film. The sample is colorless and transparent, and is firmly combined with the glass sheet, which can also be replaced by an aluminum sheet or a ceramic sheet.

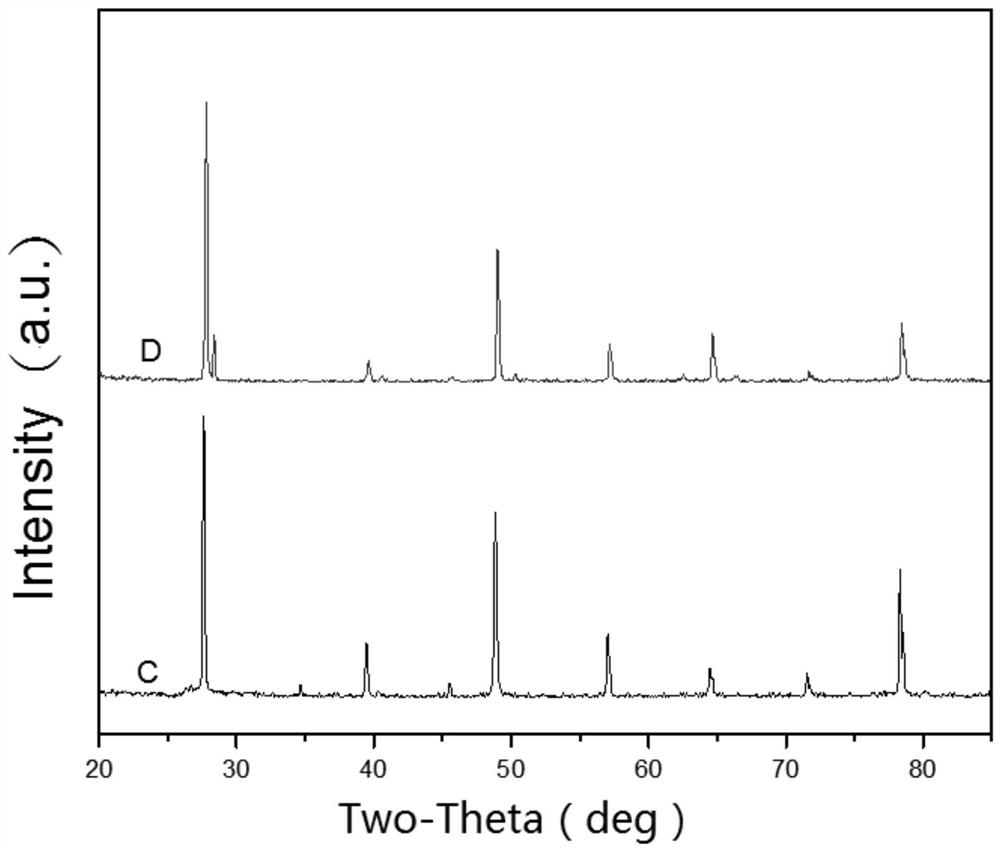

[0029] The detection results of this example are similar to those of Example 1. The analysis of the detection results shows that bot...

Embodiment 3

[0030] Embodiment 3: preparation (Cs 0.9975 Tl 0.001 In 0.0015 )(I 1.003 )film

[0031] 259.16g CsI, 0.331g TlI and 0.743g InI 3 After fully mixing, put it into a molybdenum metal evaporation boat fixed on the electrode, heat the quartz plate to 150°C by means of resistance heating, and the pressure in the hot steam chamber drops to 10 -4 torr, with Evaporate at a certain evaporation rate. During evaporation, the substrate holder rotates to ensure the uniformity of the film. When the thickness of the film reaches 30 μm, stop the evaporation. After the temperature drops to 100°C, keep it warm for 40 minutes for annealing, cool naturally to room temperature, and grow the obtained film. The sample is colorless and transparent, and is firmly combined with the quartz sheet, which can also be replaced by an aluminum sheet or a ceramic sheet.

[0032] The detection results of this example are similar to those of Example 1. The analysis of the detection results shows that both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com