Europium-doped scandium oxide scintillator, preparation method and uses thereof

A scandium oxide and scintillator technology, applied in the field of low afterglow scintillation materials, can solve the problems of high afterglow, dynamic and high-resolution X-imaging applications, and achieve high scintillation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Preparation of Sc 1.98 Eu 0.02 o 3 Scintillation single crystal, in this embodiment x is 0, y is 0.01.

[0069] Sc with a commercially available purity of 4N 2 o 3 、Eu 2 o 3 Powder is the raw material. Accurately weigh a certain mass of Sc according to the stoichiometric ratio of the above elements 2 o 3 and Eu 2 o 3 Raw material, doped Eu 2 o 3 Mix evenly with the matrix raw material, put it into an oil-resistant rubber tube, and bake it in a high-temperature furnace at 1700°C for 3 hours after isostatic pressing at 200 MPa. It is an Xe lamp, the growth atmosphere is air, the crystal growth rate is 5mm / h, and the rod rotation speed is 5rpm. After the crystal growth is completed, the temperature is slowly lowered to room temperature, and the crystal is obtained. The obtained crystal is taken off, cut and processed, and polished on both sides. The sample diameter is about 4.5 mm and the thickness is about 2 mm.

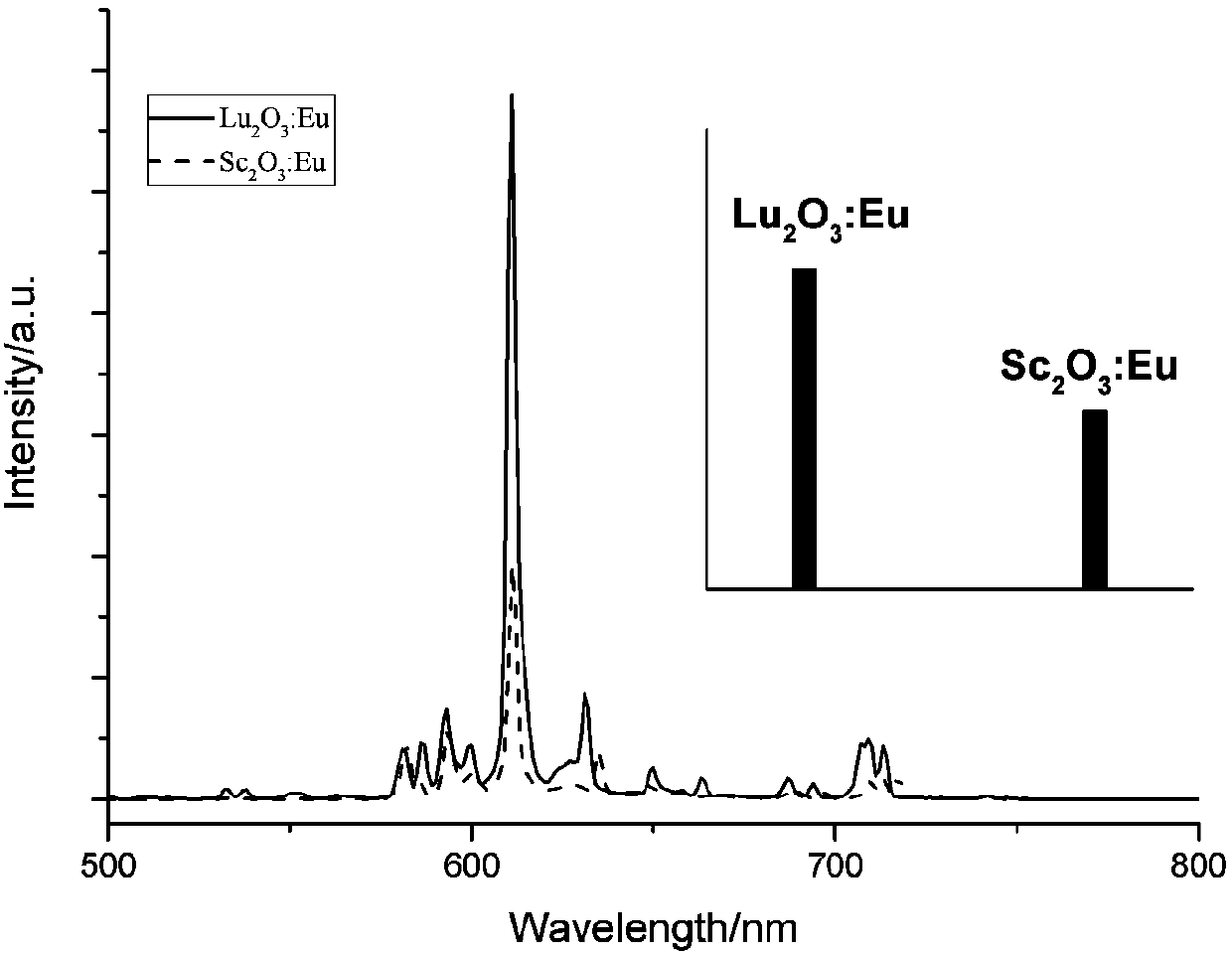

[0070] figure 1 Reflects the difference in...

Embodiment 2

[0073] Preparation of Sc 1.9 Eu 0.1 o 3 Blinking ceramic, x is 0 and y is 0.05.

[0074] Sc with a commercially available purity of 4N 2 o 3 、Eu 2 o 3 Nano as raw material. Accurately weigh a certain mass of Sc according to the above element ratio 2 o 3 and Eu 2 o 3 Raw material, using absolute ethanol as the ball milling medium. According to the mass ratio of ball mill: powder: anhydrous ethanol = 18:9:5, put it into a ball mill pot, and ball mill it on a high-speed planetary ball mill for 10 hours. The slurry obtained after ball milling was air-dried and placed in a thermostat at 50°C for 3 hours. The powder obtained by drying is passed through a 200-mesh sieve, put into a furnace, calcined at a low temperature of 1200°C, ball milled, dried, granulated, and sieved, and the obtained powder is molded under 200 MPa isostatic pressure. Put the sample into the atmosphere sintering furnace, the weak reducing atmosphere is 5% H 2 +95% Ar, sintered at 1600-1700°C for 4...

Embodiment 3

[0076] Preparation of Sc 1.84 Eu 0.16 o 3 Blinking film, x = 0, y = 0.08.

[0077] Accurately weigh Sc according to the above element ratio 2 o 3 and Eu 2 o 3 The raw materials are fully mixed, then molded under isostatic pressure of 200 MPa after mixing evenly, and sintered at a temperature of 1700° C. for 10 hours to make a polycrystalline ingot. Put the ingot into the vacuum chamber, and heat the substrate to 800°C with a vacuum of 10 -3 Pa, with Deposit at a speed of 1 / sec, and stop evaporation after the thickness of the film on the substrate reaches 200 μm; then perform annealing treatment at 600°C for 30 minutes, then cool down to room temperature, and take out the substrate after maintaining the original pressure for 3 hours . The grown film sample is colorless and transparent, and is firmly bonded to the substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com