A sound-absorbing and environmentally friendly recycled asphalt concrete and its preparation process

A technology for recycling asphalt and concrete, applied in ceramic products, other household appliances, sustainable waste treatment, etc., can solve the problems of inability to effectively reduce urban noise, poor stability, etc., achieve good sound absorption and noise reduction effect, improve stability, Guaranteed effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

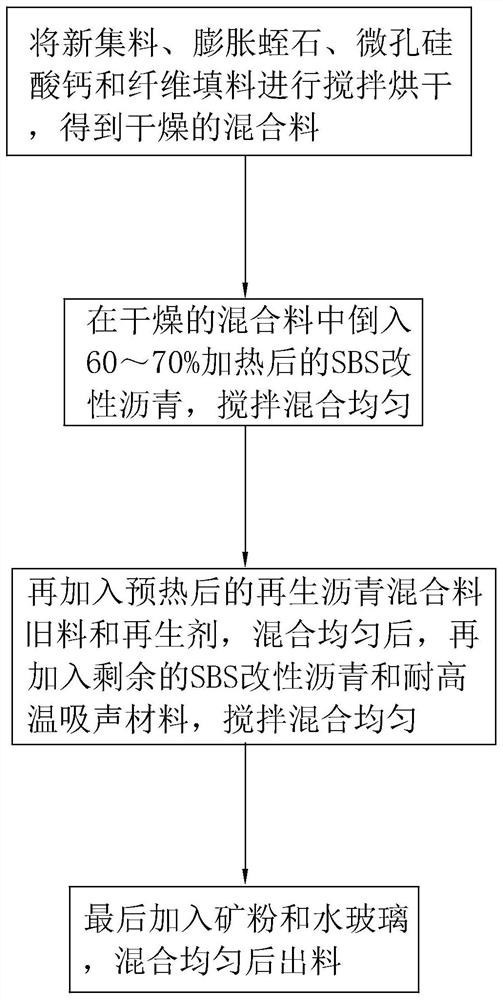

[0048] Example 1: A sound-absorbing and environmentally friendly recycled asphalt concrete, the components and their corresponding parts by weight are shown in Table 1, and were prepared through the following steps:

[0049] Step 1: Stir and dry the new aggregate, expanded vermiculite, microporous calcium silicate and polyester fiber in the drying barrel with the corresponding weight parts, the temperature is controlled at 110°C, the time is 20min, and the stirring speed is 900rpm , to obtain a dry mixture;

[0050] Step 2, put the dry mixture into the mixing tank, heat 60% by weight of SBS modified asphalt to 160°C, add it into the mixing tank evenly within 30s, and stir at a stirring speed of 1200rpm for 20min;

[0051] Step 3: Preheat the regenerated asphalt mixed old material to 80°C and add it together with the regeneration agent into the above mixing tank for stirring. The temperature in the mixing tank is maintained at 170°C, the stirring speed is 1100rpm, and the time...

Embodiment 2-8

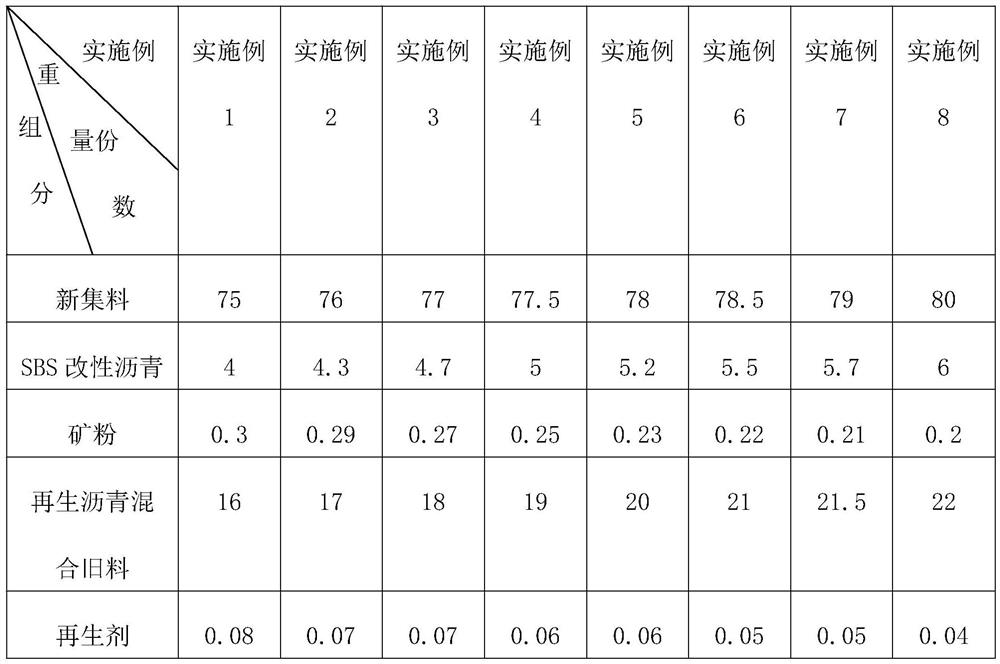

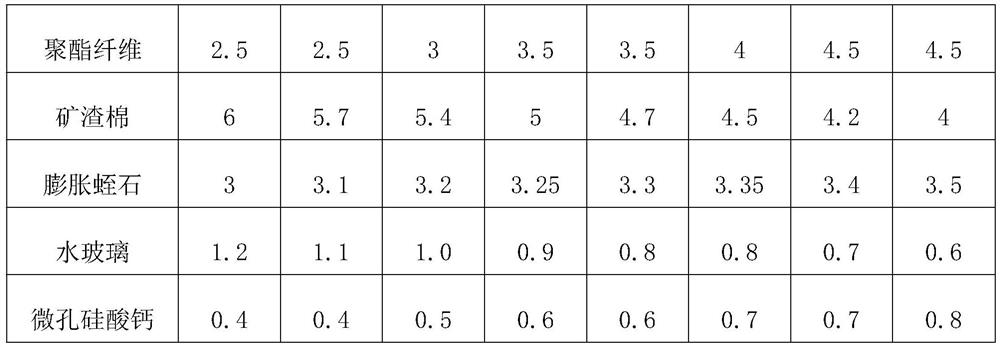

[0054] Example 2-8: A sound-absorbing and environment-friendly recycled asphalt concrete. The difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0055] Each component and parts by weight thereof in table 1 embodiment 1-8

[0056]

[0057]

Embodiment 9

[0058] Example 9: A sound-absorbing and environmentally friendly recycled asphalt concrete. The difference from Example 1 is that the new aggregate mainly has a particle size range of 0-3mm, 3-5mm, 5-13mm, 13-20mm, 20- The 25mm limestone is composed of 1.4:2.6:7.6:1:3.5 in parts by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com