Improved integrated septic tank based on carbon fiber thermoplastic composite material

A composite material and thermoplastic technology, which is applied in the field of improved integrated septic tanks, can solve the problems of increased process difficulty, limited size specifications, and complicated processes, and achieve the effects of convenient and quick installation, expanded use range, and improved compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

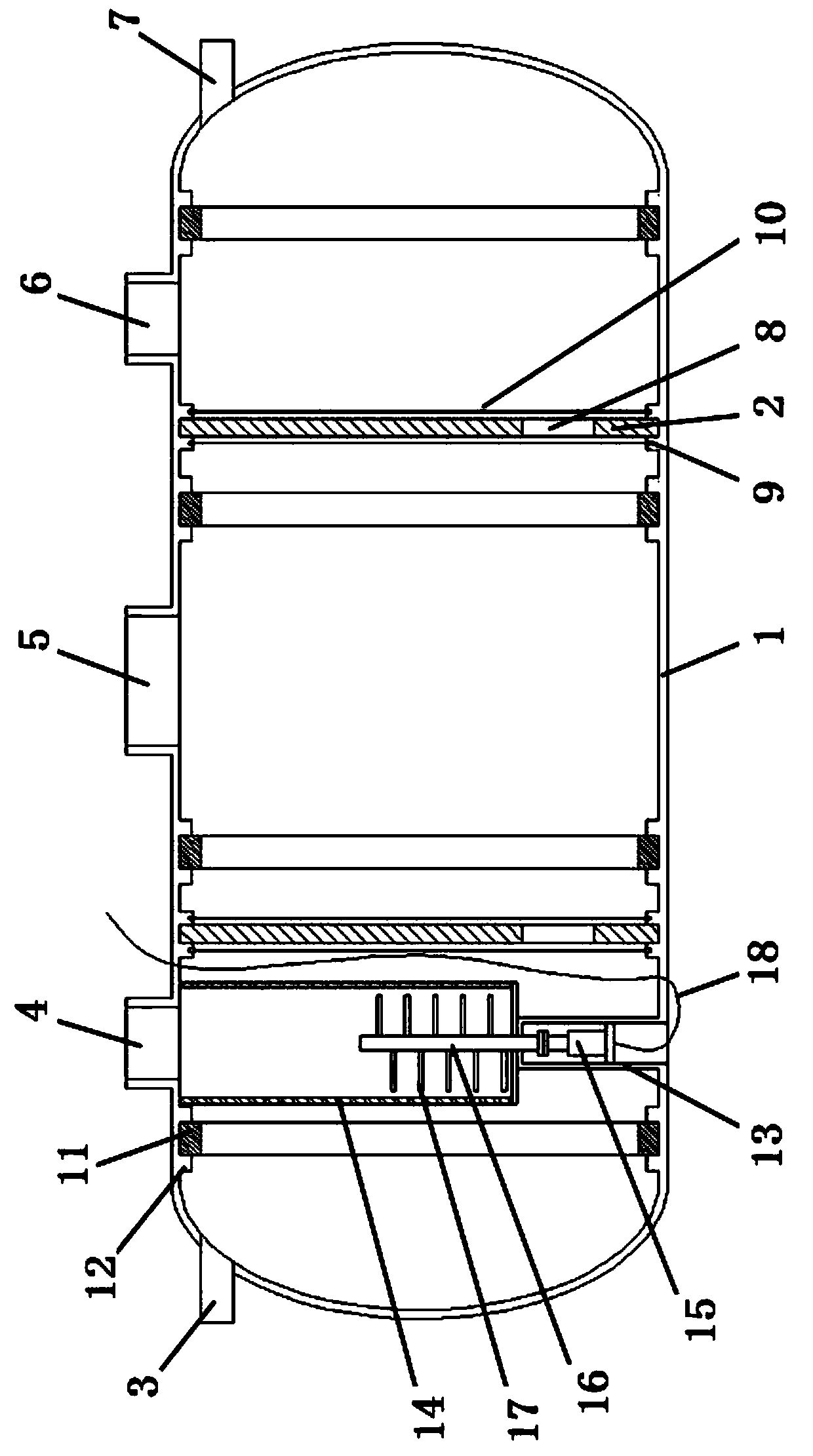

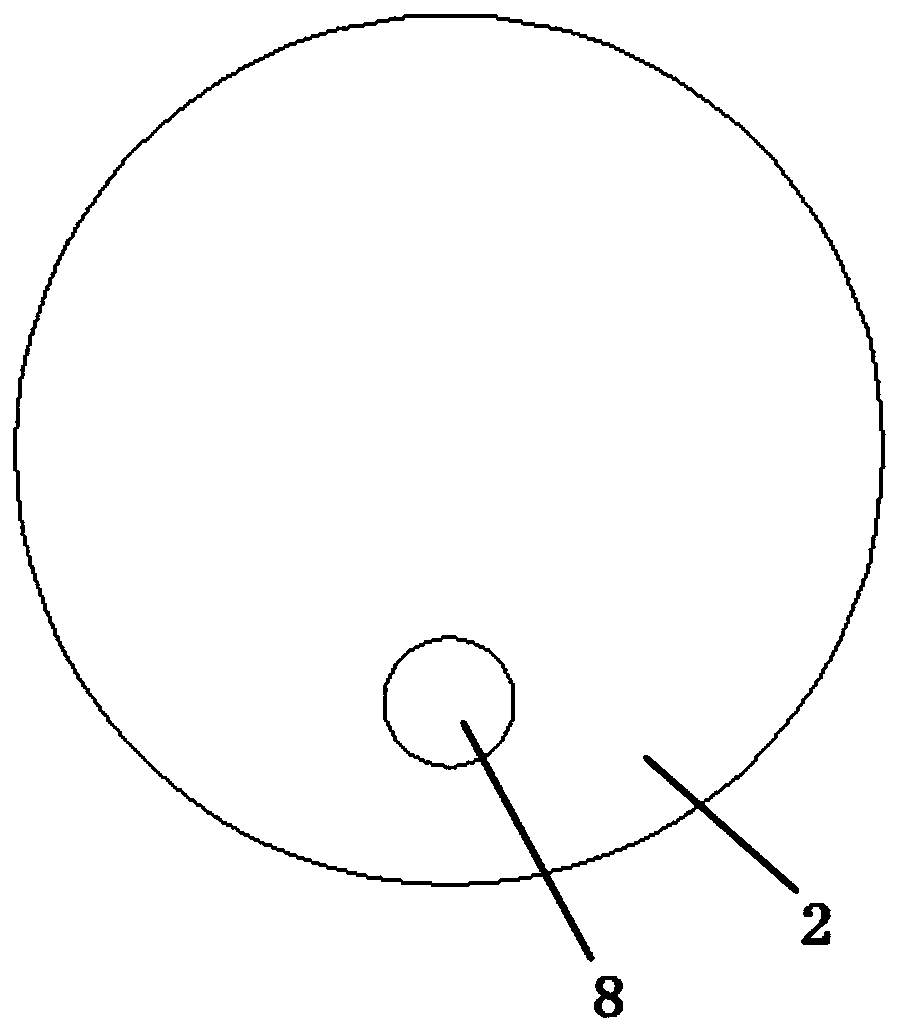

[0034] see Figure 1-6 As shown, this embodiment is an improved integrated septic tank based on carbon fiber thermoplastic composite material, including a shell 1 made of carbon fiber thermoplastic composite material, and the inner area of the shell 1 is divided into one by two partitions 2 Class anaerobic chamber, secondary anaerobic chamber and clarification chamber. The side of the primary anaerobic chamber is provided with a water inlet 3, and the upper part is provided with an inlet pipe 4. The upper part of the secondary anaerobic chamber is provided with an inspection port 5, and the size of the inspection port 5 supports the staff to enter to complete the assembly work before use. The side of the clarification chamber is provided with a water outlet 7, and the top of the clarification chamber is provided with an outlet pipe 6 which can be used as a sampling port.

[0035] The partition 2 and the housing 1 are in a separate structure. The partition 2 is a flexible c...

Embodiment 2

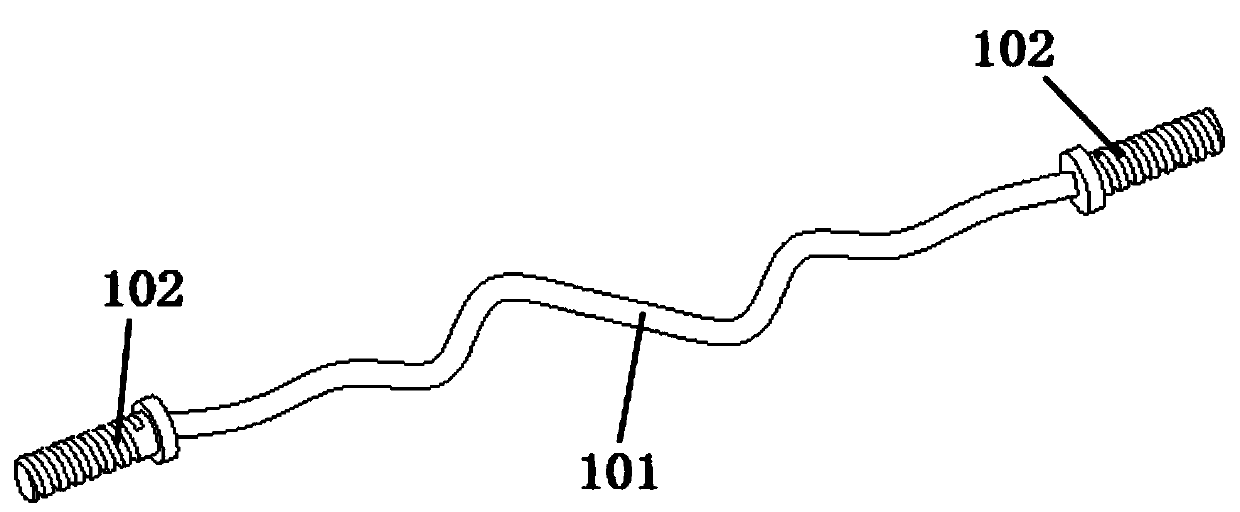

[0041] The structure and application of this embodiment are basically the same as that of Embodiment 1, and the differences are as follows: Figure 7 As shown, the anti-collapse ropes 10 on each side are distributed in a star shape, and the lengths of the rope bodies 101 are the same, and cross on the extension line of the axis of the partition 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com