Molding slag for continuous casting of high-alumina steel and its preparation method and application

A technology of mold slag and high-aluminum steel, which is applied in the field of metallurgy, can solve the problems of changing the composition and performance of mold slag, deterioration of the lubrication performance of the mold slag, and personal hazards, achieving good lubrication effect, reducing sags, and reducing fluorine pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

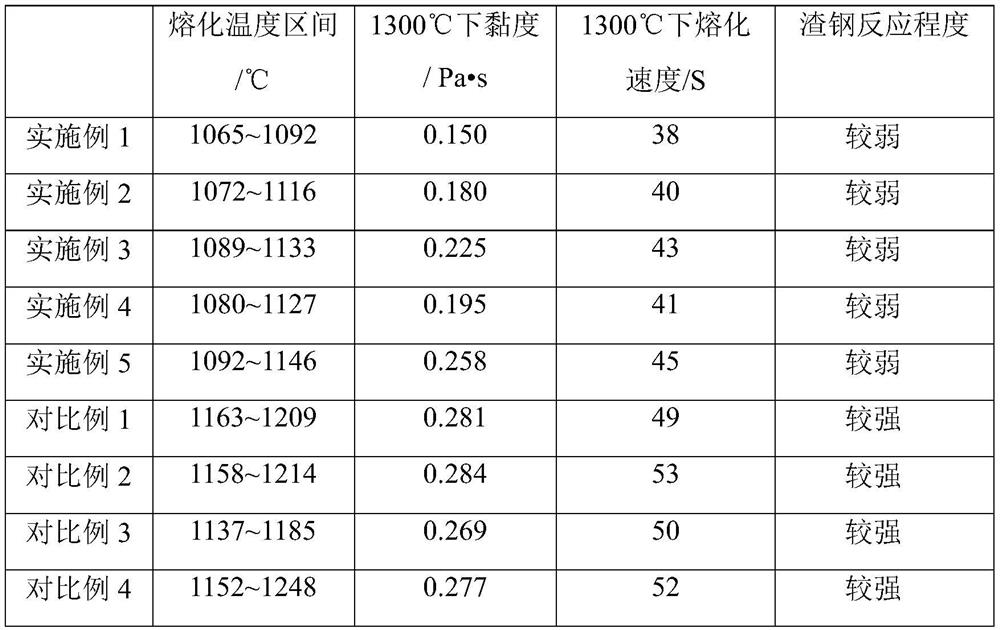

Embodiment 1

[0036] This example provides a method for preparing mold flux for continuous casting of high-aluminum steel. The mass fraction of each raw material of mold flux is as follows: Al 2 o 3 : 40%, MgO: 21%, B 2 o 3 : 10%, CaO: 3%, MnO: 5%, carbonaceous material: 8%, SiO 2 :3%, CaF 2 : 3%, Na 2 O: 3%, Li 2 O: 3%, K 2 O: 1%.

[0037] In this embodiment, the production process of mold flux includes the following steps:

[0038]S1. Take the mixture of each raw material (except carbonaceous material) in proportion, and carry out pre-melting treatment in the melting furnace;

[0039] S2. quenching, pulverizing and drying the pre-melted mixture to make a base material with a particle size of about 0.04mm;

[0040] S3. Add carbonaceous material to the base material and mix evenly;

[0041] S4. Transport the mixture in step S4 to a spray granulation tower for atomization granulation and drying, and the dried granules pass through a 0.1-1mm sieve to obtain mold flux for continuous ...

Embodiment 2

[0043] This example provides a method for preparing mold flux for continuous casting of high-alumina steel. The production process of mold flux is consistent with that of Example 1. The mass fraction of each raw material of mold flux is as follows: Al 2 o 3 : 41%, MgO: 22%, B 2 o 3 : 12%, CaO: 3%, MnO: 4%, carbonaceous material: 5%, SiO 2 :3%, CaF 2 : 3%, Na 2 O: 3%, Li 2 O: 3%, K 2 O: 1%.

Embodiment 3

[0045] This example provides a method for preparing mold flux for continuous casting of high-alumina steel. The production process of mold flux is consistent with that of Example 1. The mass fraction of each raw material of mold flux is as follows: Al 2 o 3 : 45%, MgO: 20%, B 2 o 3 : 10%, CaO: 4%, MnO: 4%, carbonaceous material: 6%, SiO 2 :3%, CaF 2 : 2%, Na 2 O: 2%, Li 2 O: 2%, K 2 O: 2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com