Fluidized bed catalyst for preparing aromatic hydrocarbons from methanol

A technology for fluidized bed catalysts and aromatics, applied in physical/chemical process catalysts, molecular sieve catalysts, catalyst activation/preparation, etc., can solve the problems of low chlorine content in catalysts, high residual chlorine content in catalysts, and large equipment corrosion risks, etc. problem, achieve the effect of reducing the risk of corrosion and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

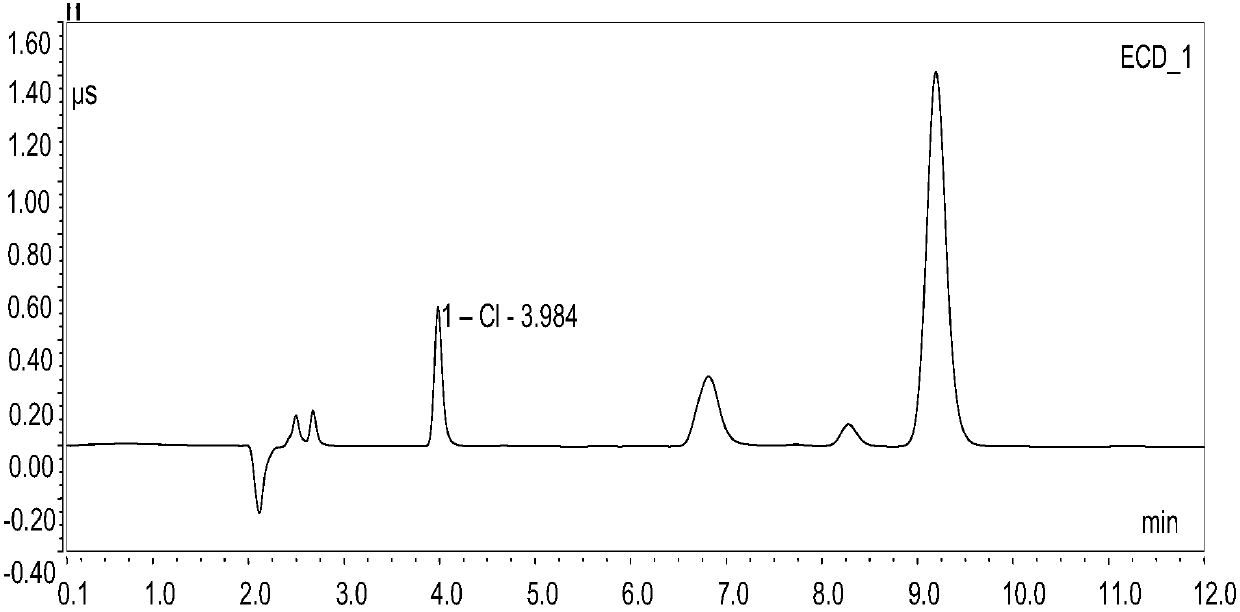

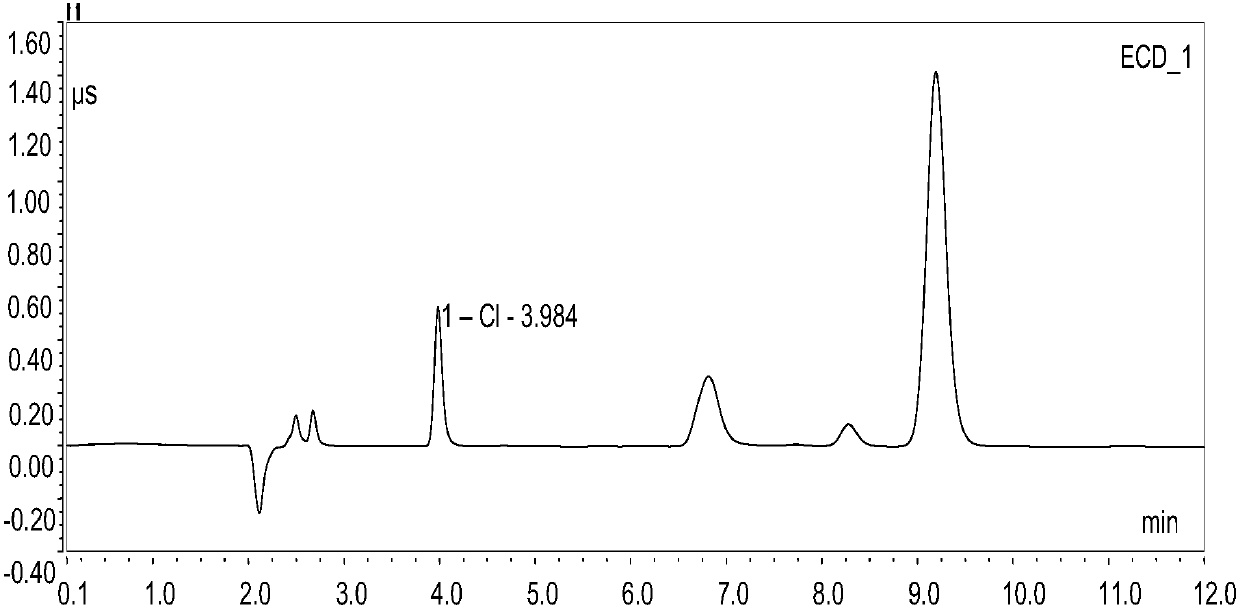

Image

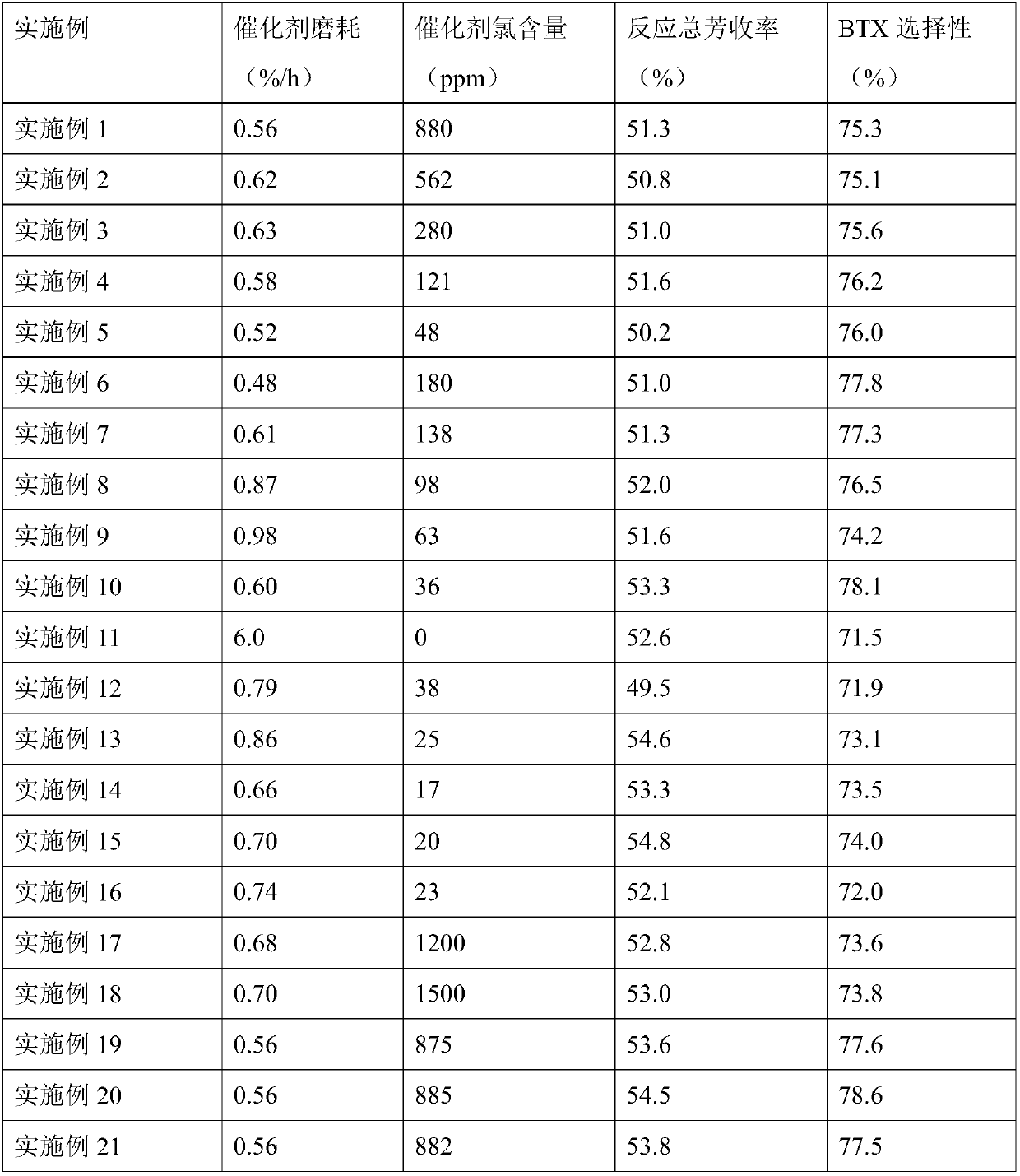

Examples

Embodiment 1

[0031] (1) Weigh 100g of ZSM-5 and 80g of β molecular sieve, add it to 300g of phosphoric acid aqueous solution with a mass concentration of 5%, stir and mix for 30 minutes, then heat and evaporate the water to dryness, then roast it at 500°C for 3 hours to obtain a phosphorus-modified molecular sieve ;

[0032] (2) Weighing 300g of aluminum sol and mixing it with 100g of phosphoric acid aqueous solution with a mass concentration of 5%, and mixing at 60°C for 30 minutes to obtain a phosphorus-modified binder;

[0033] (3) uniformly mix the above-mentioned phosphorus-modified molecular sieve with phosphorus-modified binder, kaolin, and water in proportion, then adopt spray drying to form, and obtain a catalyst precursor through roasting at 500° C. for 4 hours;

[0034] (4) The catalyst precursor obtained above was contacted with 100% steam for 1 hour at 300°C, and the space velocity of the steam was 1h -1 , and then the temperature was lowered, and the catalyst precursor was l...

Embodiment 2

[0037] (1) Weigh 100g of ZSM-5 and 80g of beta molecular sieve, add it to 300g of phosphoric acid aqueous solution with a mass concentration of 5%, stir and mix for 30 minutes, then heat and evaporate the water to dryness, then roast it at 500°C for 3 hours to obtain phosphorus-modified molecular sieve ;

[0038] (2) Weighing 300g of aluminum sol and mixing it with 100g of phosphoric acid aqueous solution with a mass concentration of 5%, and mixing at 60°C for 30 minutes to obtain a phosphorus-modified binder;

[0039] (3) uniformly mix the above-mentioned phosphorus-modified molecular sieve with phosphorus-modified binder, kaolin, and water in proportion, then adopt spray drying to form, and obtain a catalyst precursor through roasting at 500° C. for 4 hours;

[0040] (4) The catalyst precursor obtained above was contacted with 100% steam for 2 hours at 400°C, and the space velocity of the steam was 1h -1 , and then the temperature was lowered, and the catalyst precursor was...

Embodiment 3

[0043] (1) Weigh 100g of ZSM-5 and 80g of beta molecular sieve, add it to 300g of phosphoric acid aqueous solution with a mass concentration of 5%, stir and mix for 30 minutes, then heat and evaporate the water to dryness, then roast it at 500°C for 3 hours to obtain phosphorus-modified molecular sieve ;

[0044] (2) Weighing 300g of aluminum sol and mixing it with 100g of phosphoric acid aqueous solution with a mass concentration of 5%, and mixing at 60°C for 30 minutes to obtain a phosphorus-modified binder;

[0045] (3) uniformly mix the above-mentioned phosphorus-modified molecular sieve with phosphorus-modified binder, kaolin, and water in proportion, then adopt spray drying to form, and obtain a catalyst precursor through roasting at 500° C. for 4 hours;

[0046] (4) The catalyst precursor obtained above was contacted with 100% steam for 4 hours at 500°C, and the space velocity of the steam was 1h -1 , and then the temperature was lowered, and the catalyst precursor was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com