Composite material fan blade integrating large clearance

A technology of composite materials and blowers, applied in the direction of liquid fuel engines, supporting elements of blades, mechanical equipment, etc., can solve problems such as complex execution of solutions, inappropriateness of blower blades, negative impact of blade surface state, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

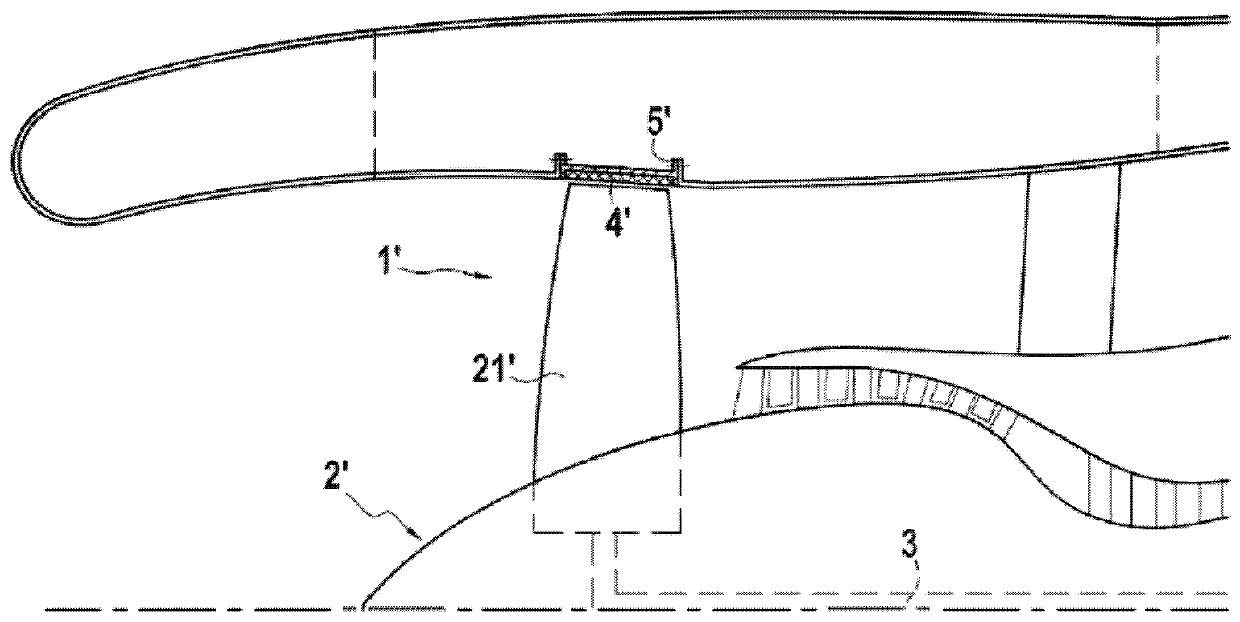

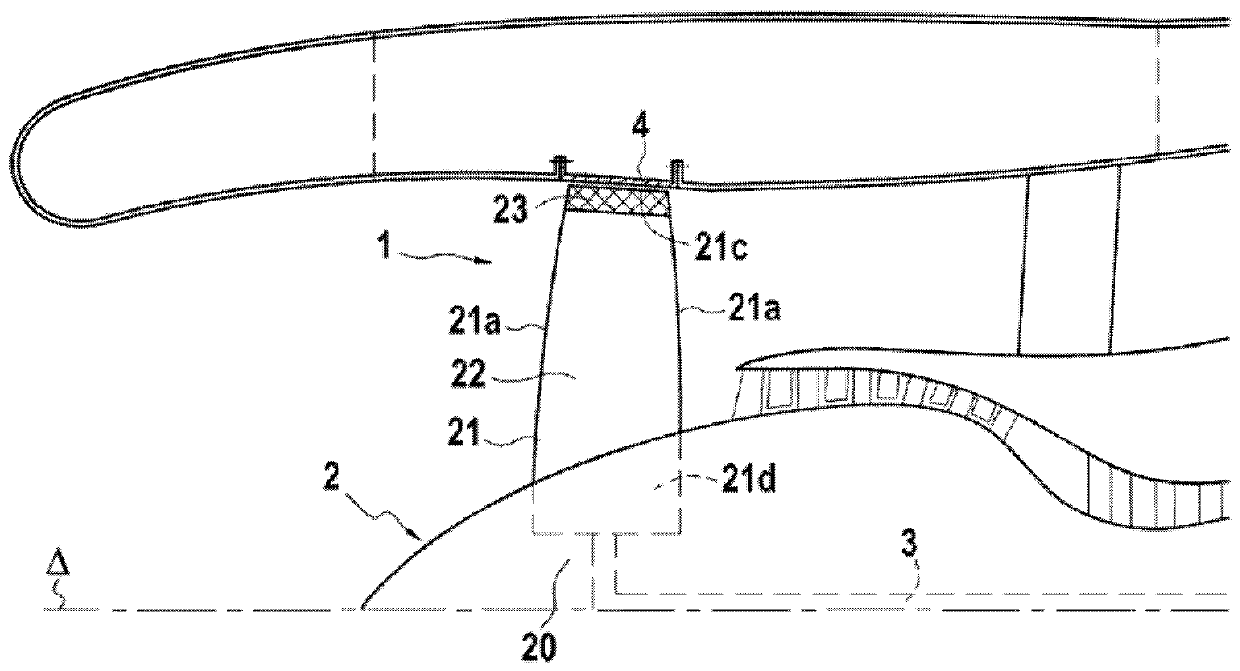

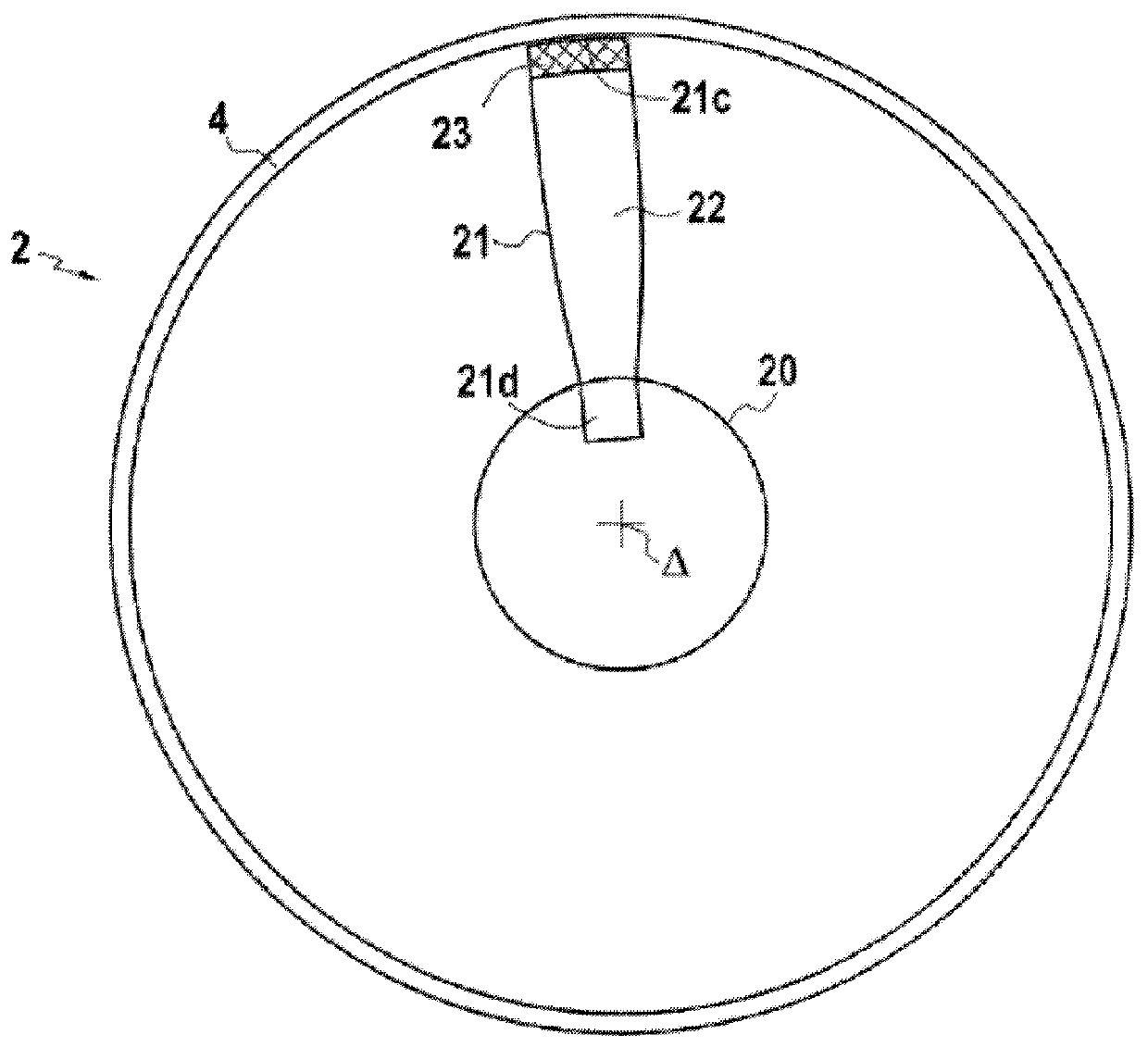

[0052] Such as figure 2 , Figure 3A with Figure 3B As shown, the turbine engine 1 has a blower 2 including a plurality of blades 21. For simplicity, a single blade 21 is shown in the figure. The blower 2 is driven by the blower shaft 3 to rotate around the axis Δ of the turbine engine 1. The blower shaft 3 may be constituted by the low pressure shaft of the turbine engine 1, or the blower shaft 3 may be driven to rotate by the low pressure shaft via a reduction gear.

[0053] The blower shaft 3 is fixed to the remaining part of the turbine engine 1 by a bearing to allow the blower shaft to rotate. Among the bearings of the fixed blower shaft 3, the turbine engine includes at least one main bearing and at least one separator bearing, the at least one separator bearing having a fracture limit lower than the limit of the at least one main bearing. Therefore, the separator bearing or each separator bearing serves as a sacrificial bearing by breaking under the effect of the imbala...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com