Hollow spiral-blade heating thin-film evaporator and evaporation method

A helical blade, heating and evaporation technology, applied in evaporator accessories, chemical instruments and methods, evaporation and other directions, can solve the problems of high power consumption of rotating scrapers, inability to produce large-scale equipment, and high processing accuracy requirements, and achieve simple and reliable equipment. The effect of avoiding build-up and scaling, low processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can understand.

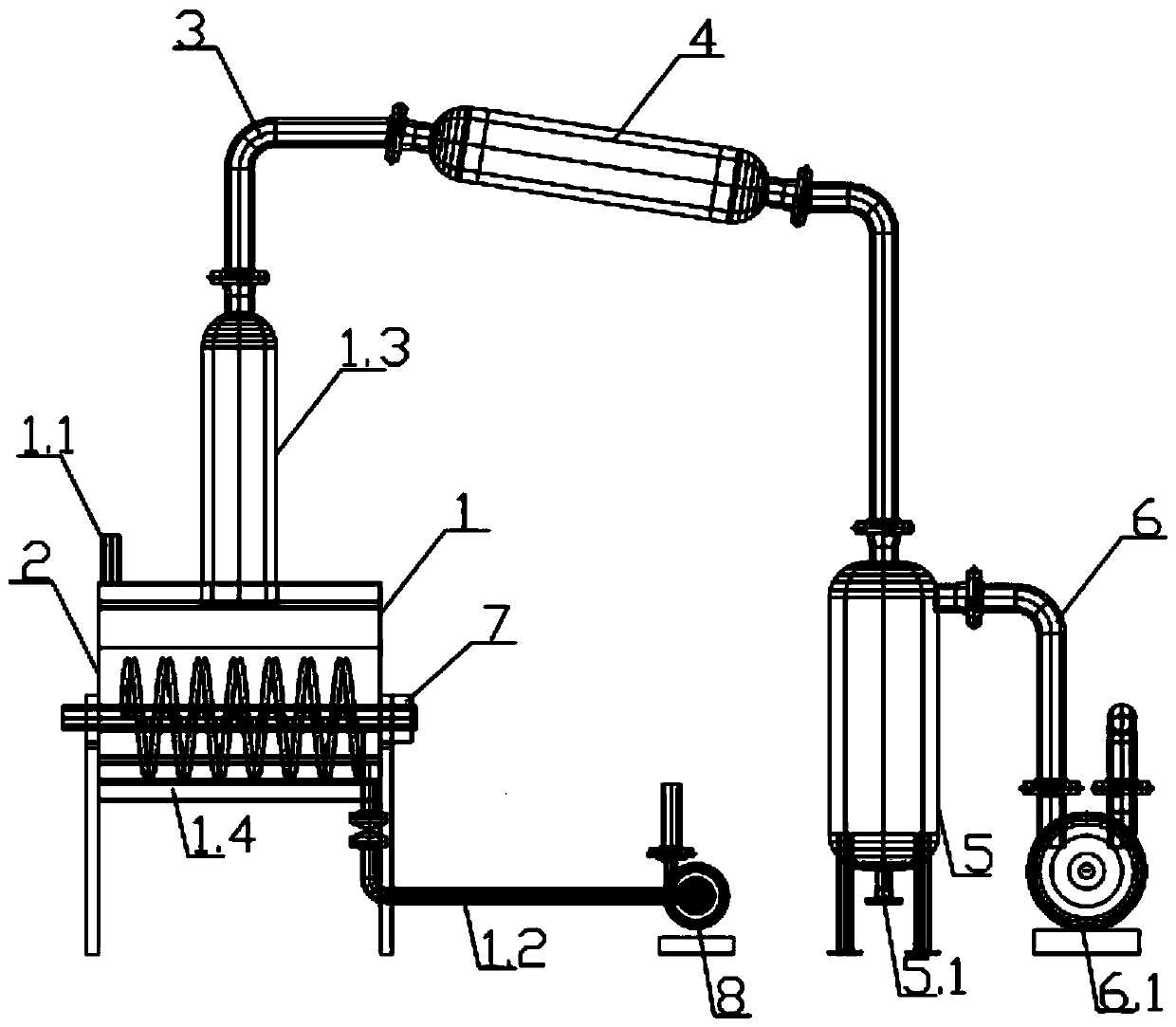

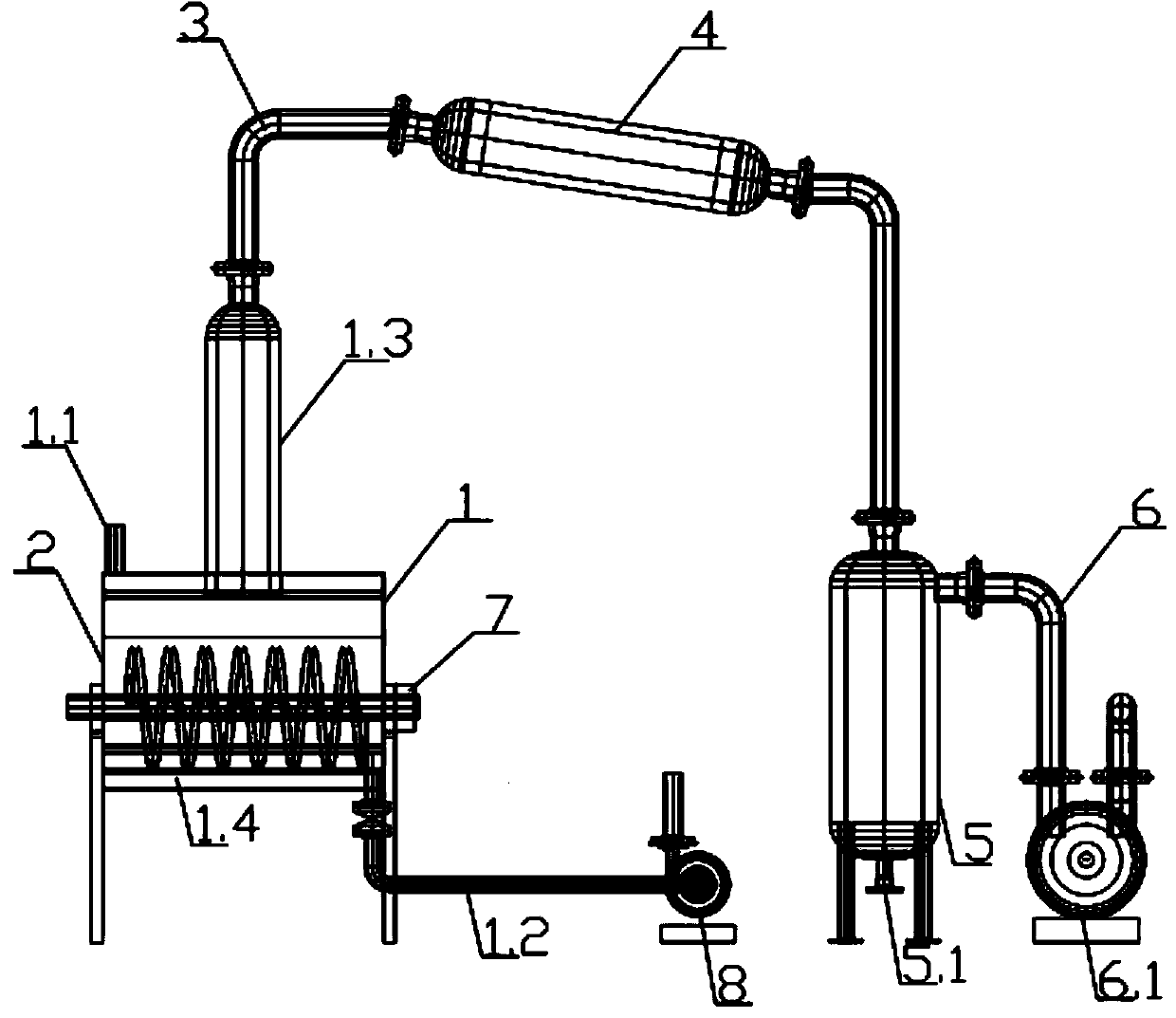

[0030] Such as Figure 1~2 The shown hollow spiral blade heating film evaporator includes a heating evaporation tank 1, a feed pipe 1.1 is arranged on the upper tank wall of the heating evaporation tank 1, and a discharge pipe 1.2 is arranged on the lower tank wall of the heating evaporation tank 1, and the discharge pipe 1.2 is arranged on the lower tank wall of the heating evaporation tank 1. A discharge pump 8 is arranged on the pipe 1.2, and a heating jacket 1.4 is arranged outside the heating evaporation tank 1;

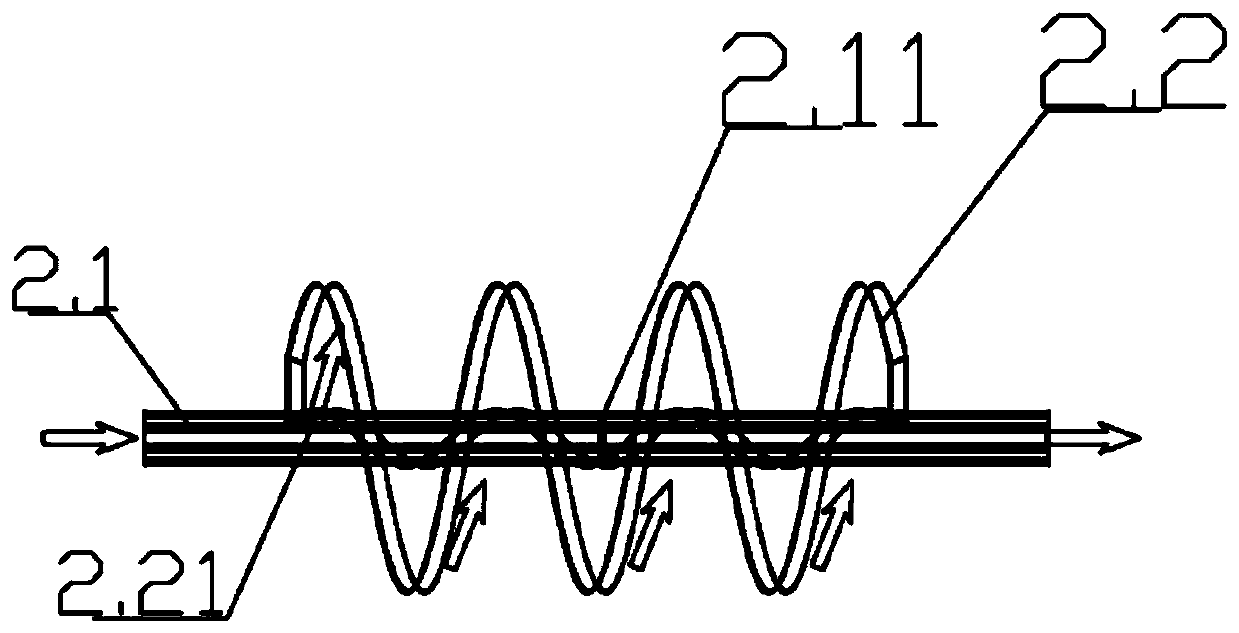

[0031] The heating evaporation tank 1 is provided with a hollow spiral blade heating device 2, and the tank wall of the heating evaporation tank 1 is connected with a steam outlet pipe 1.3. The bottom plate of the water tank 5 is provided with an outlet pipe 5.1;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com