Graphene anti-microbial shoe pads and preparation method thereof

A graphene, graphene modification technology, applied in insoles, footwear, clothing and other directions, can solve the problems of insoles not resistant to washing, reduced antibacterial effect, loss of antibacterial agents, etc., to achieve excellent antibacterial performance, not easy to fall off, excellent Antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

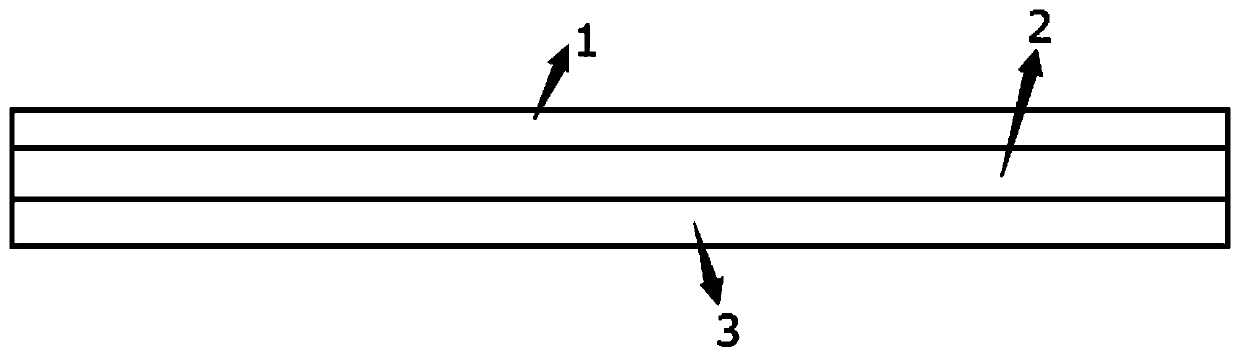

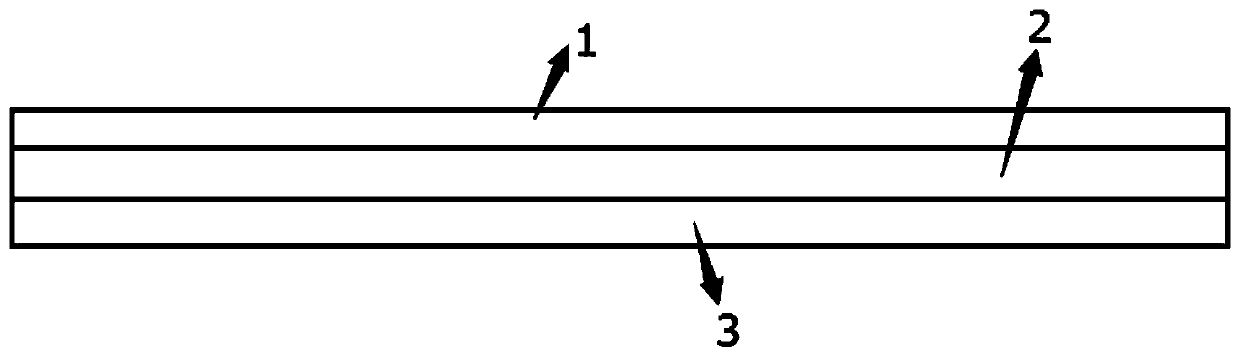

[0028] This embodiment provides a figure 1 The preparation method of shown graphene antibacterial insole specifically comprises the steps:

[0029] Physically mix the modified graphene oxide and polypropylene powder, and extrude at 130-180°C to obtain graphene-modified polypropylene fiber masterbatch, wherein the amount of modified graphite oxide added is 1 / 2 of the weight of polypropylene powder 1%;

[0030] After mixing the graphene-modified polypropylene masterbatch and polypropylene resin, extrude at 150-200°C, and then go through spinning, cooling, drawing, web forming, pressing roll, hot rolling, winding and slitting , obtaining the graphene polypropylene spunbonded non-woven fabric;

[0031] The velvet cloth is used as the skin-touching layer fabric, the graphene polypropylene spun-bonded non-woven fabric is used as the antibacterial functional layer fabric, and the EVA is used as the elastic shock-resistant layer fabric, and the graphene antibacterial insole is obtai...

Embodiment 2

[0034] This embodiment provides a figure 1 The preparation method of shown graphene antibacterial insole specifically comprises the steps:

[0035] Physically mix the modified graphene oxide and polypropylene powder, and extrude at 130-180°C to obtain graphene-modified polypropylene fiber masterbatch, wherein the amount of modified graphite oxide added is 1 / 2 of the weight of polypropylene powder 8%;

[0036] After mixing the graphene-modified polypropylene masterbatch and polypropylene resin, extrude at 150-200°C, and then go through spinning, cooling, drawing, web forming, pressing roll, hot rolling, winding and slitting , obtaining the graphene polypropylene spunbonded non-woven fabric;

[0037] The Lycra mesh is used as the skin-touching layer fabric, the graphene polypropylene spunbonded non-woven fabric is used as the antibacterial functional layer fabric, and the sponge is used as the elastic shockproof layer fabric, and the graphene antibacterial insole is obtained b...

Embodiment 3

[0040] This embodiment provides a figure 1 The preparation method of shown graphene antibacterial insole specifically comprises the steps:

[0041] Physically mix the modified graphene oxide and polypropylene powder, and extrude at 130-180°C to obtain graphene-modified polypropylene fiber masterbatch, wherein the amount of modified graphite oxide added is 1 / 2 of the weight of polypropylene powder 4.5%;

[0042] After mixing the graphene-modified polypropylene masterbatch and polypropylene resin, extrude at 150-200°C, and then go through spinning, cooling, drawing, web forming, pressing roll, hot rolling, winding and slitting , obtaining the graphene polypropylene spunbonded non-woven fabric;

[0043] The comfortable plush is used as the skin-touching layer fabric, the graphene polypropylene spunbonded non-woven fabric is used as the antibacterial functional layer fabric, and the silica gel is used as the elastic shockproof layer fabric, and the graphene antibacterial insole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com