Production process of edible mushrooms pleurotus ostreatus

A production process, the technology of small oyster mushrooms, applied in horticulture, application, mushroom cultivation, etc., can solve the problems of time-consuming, pollution, increase of temperature diversion methods, etc., and achieve the effect of fast growth of bacteria and more growth points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

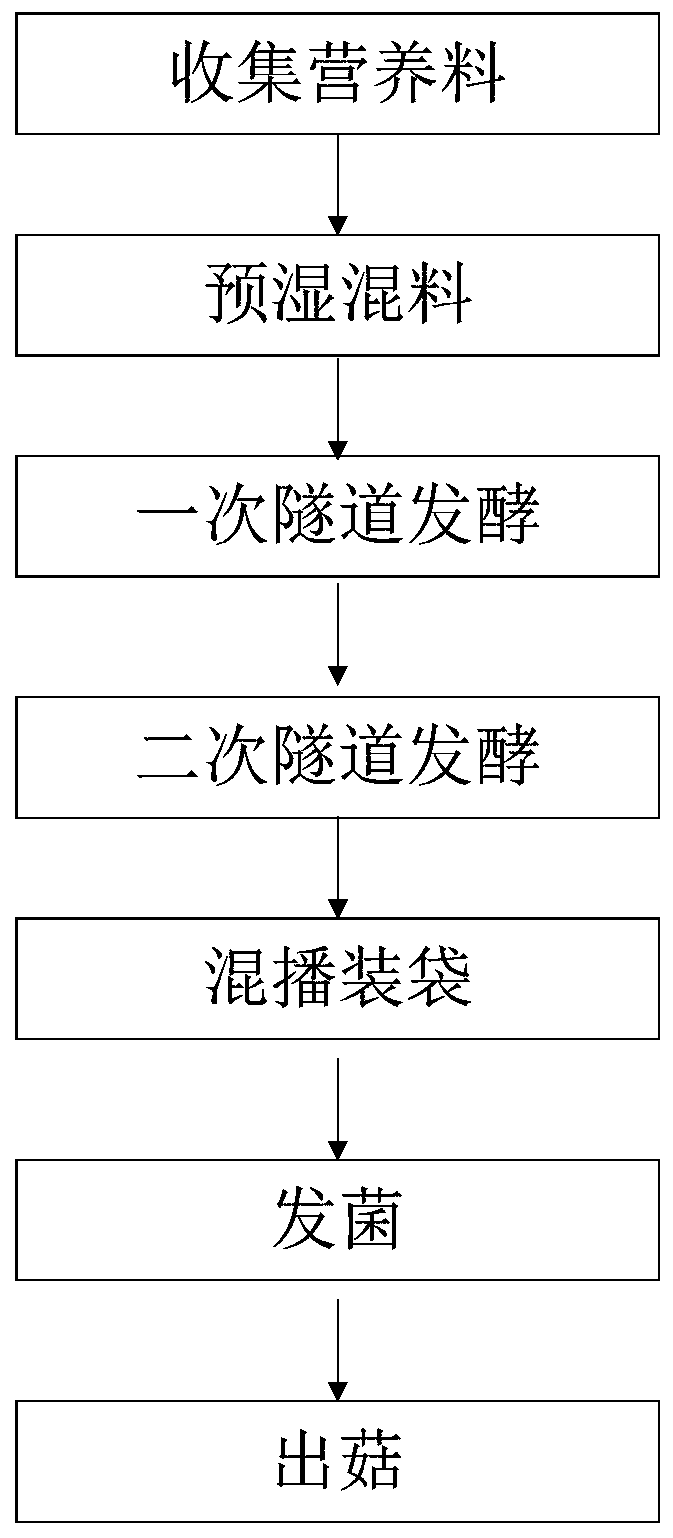

[0027] figure 1 It is a flow chart of the production process embodiment of a kind of edible fungus Pleurotus ostreatus of the present invention, as shown in the figure, the present invention provides a kind of production technology of edible fungus Pleurotus ostreatus, comprises the following steps:

[0028] (1) Collect nutrients: prepare 65%-75% Pleurotus eryngii waste, 10%-20% corncobs, 10%-20% cottonseed hulls and 15-25 tons of fresh chicken manure;

[0029] (2) Pre-wet mixture: first build a mixture pre-wet tank, put the nutrient material in the mix pre-wet tank to pre-wet in advance, mix the material for 2 days, get the pre-wet mixture, and prepare for entering a tunnel fermentation ;

[0030] (3) One-time tunnel fermentation: using the Agaricus bisporus fermentation process, carry out one-time tunnel fermentation on the pre-wet mixture, and the fermentation time is 6 days;

[0031] (4) Secondary tunnel fermentation: the mixed material after the primary tunnel fermentat...

Embodiment 2

[0037] Nutrients in the above step (1) are 70% Pleurotus eryngii waste, 15% corncobs, 15% cottonseed hulls and 20 tons of fresh chicken manure.

[0038] Therefore, the present invention adopts the production process of the above-mentioned edible fungus Oyster ostreatus, keeps the desired temperature of the tunnel, saves costs, reduces pests and diseases, does not produce pollution through good ventilation, has fast bacterial growth, is easy to operate, and has strong strain vitality. Reduced production time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com