Drip tray for a compact machine compartment and refrigerator using a drip tray

A technology for defrosting water and mechanical rooms, applied in defrosting, applications, household appliances, etc., can solve the problems of reduced air volume, reduced height h and depth d of mechanical rooms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

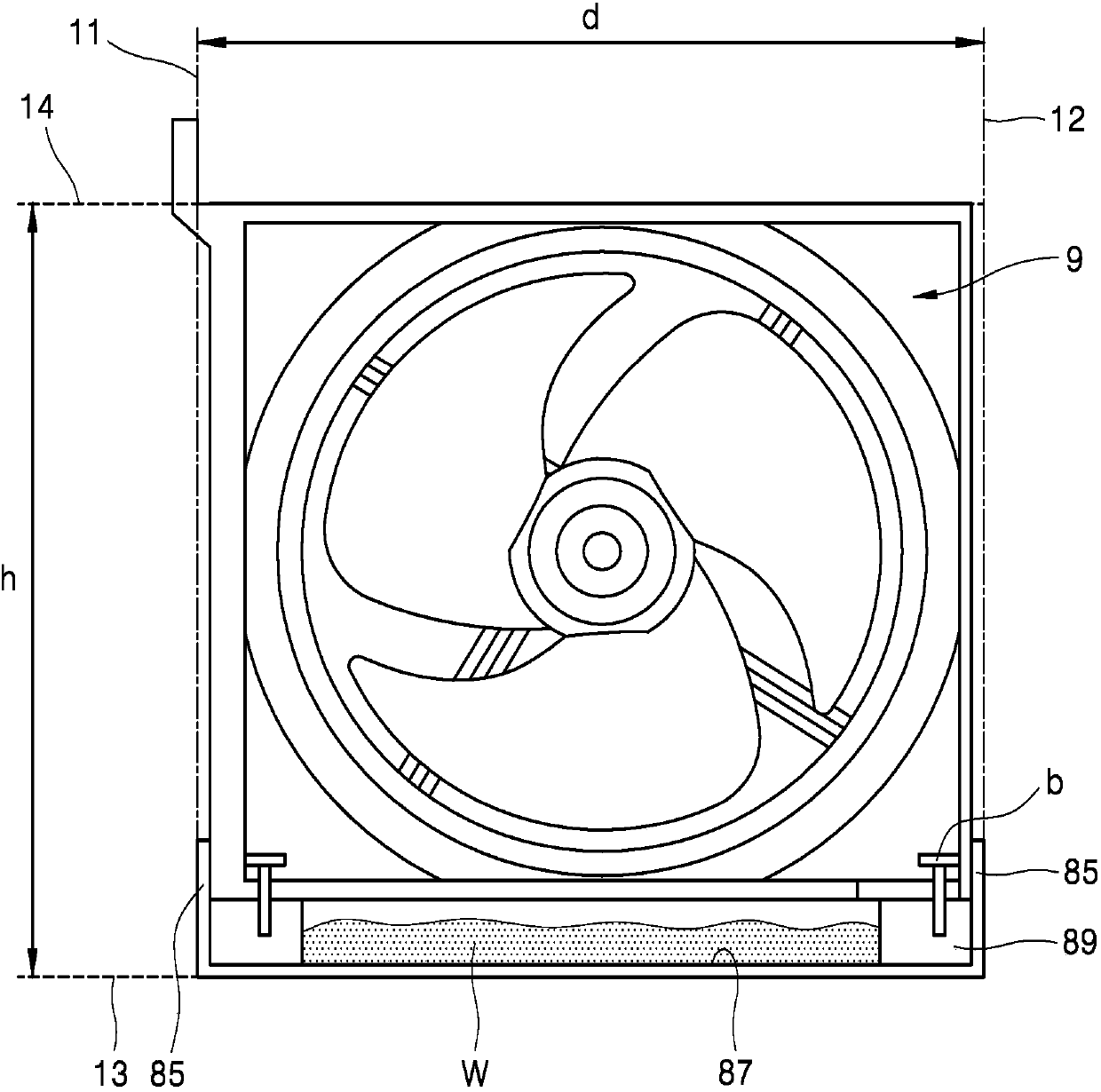

Image

Examples

no. 1 example

[0111] According to the first embodiment, defroster tank 7 includes: an outer wall surrounding both short sides and one long side of rectangular bottom member 77; That is, the outer wall 75 is provided so as to surround all parts except the opening 78 at the edge of the bottom member 77 .

[0112] Furthermore, an inner wall 76 is connected to the outer wall 75 and extends from the edge of the bottom member 77 to the inside.

[0113] Therefore, the outer wall 75 and the inner wall 76 of the defrosting tank 7 are connected in a closed loop shape.

[0114] The space defined by the bottom member 77 and the inner area of the closed loop formed by the outer wall 75 and the inner wall 76 forms a defrosting water storage space 71 .

[0115] The defrosting water storage space 71 is divided into two spaces roughly divided by the inner wall 76 . Based on the length direction of the long side of the bottom member 77 , a first storage space 711 is provided on one side of the inner wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com