Daylighting roof steel structure mounting method

An installation method and technology of steel structure, applied in the direction of roof, building components, building structure, etc., can solve the problems of high height of full house, long construction period, and many construction personnel, so as to reduce construction cost, improve construction efficiency, and improve The effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

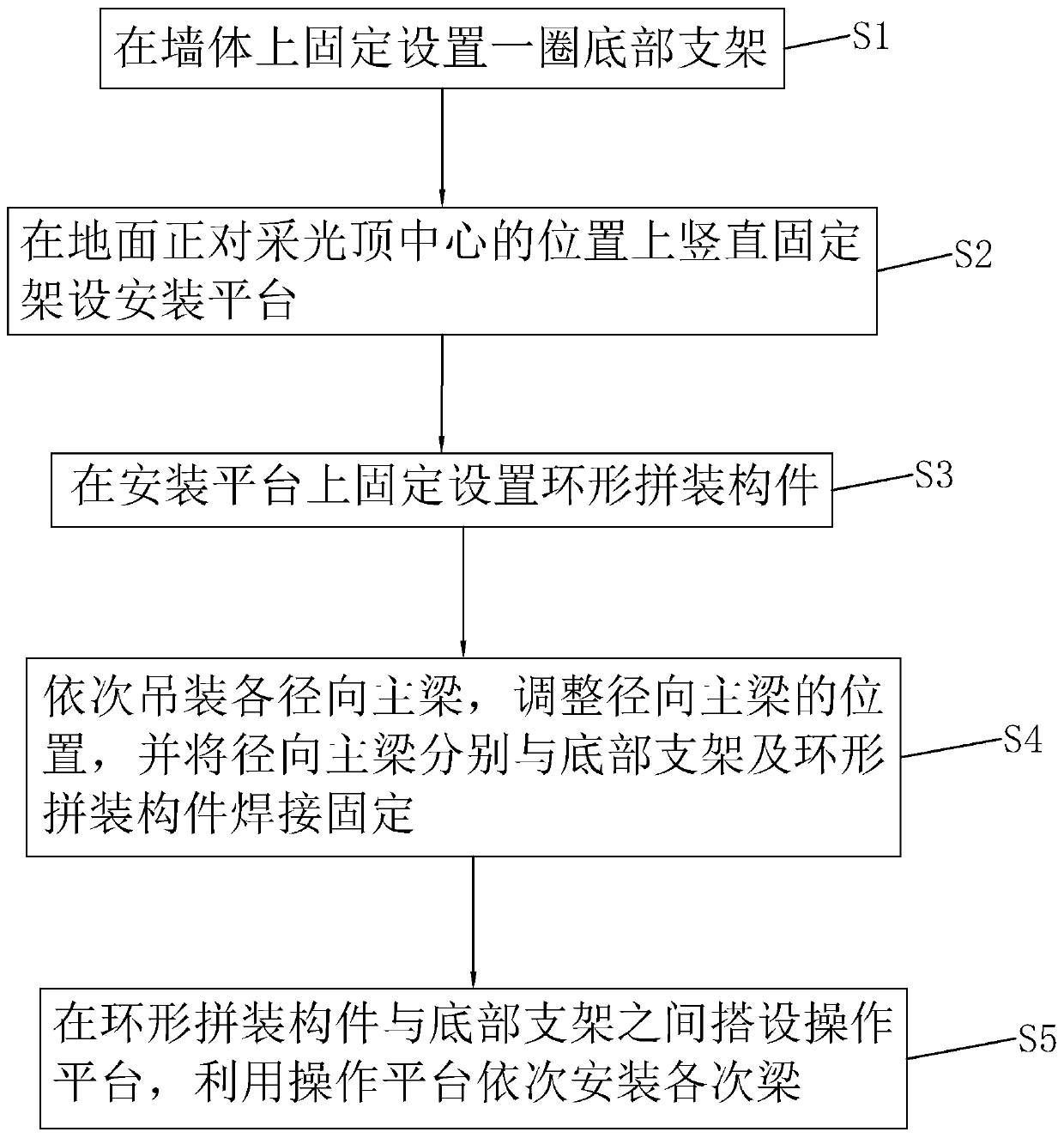

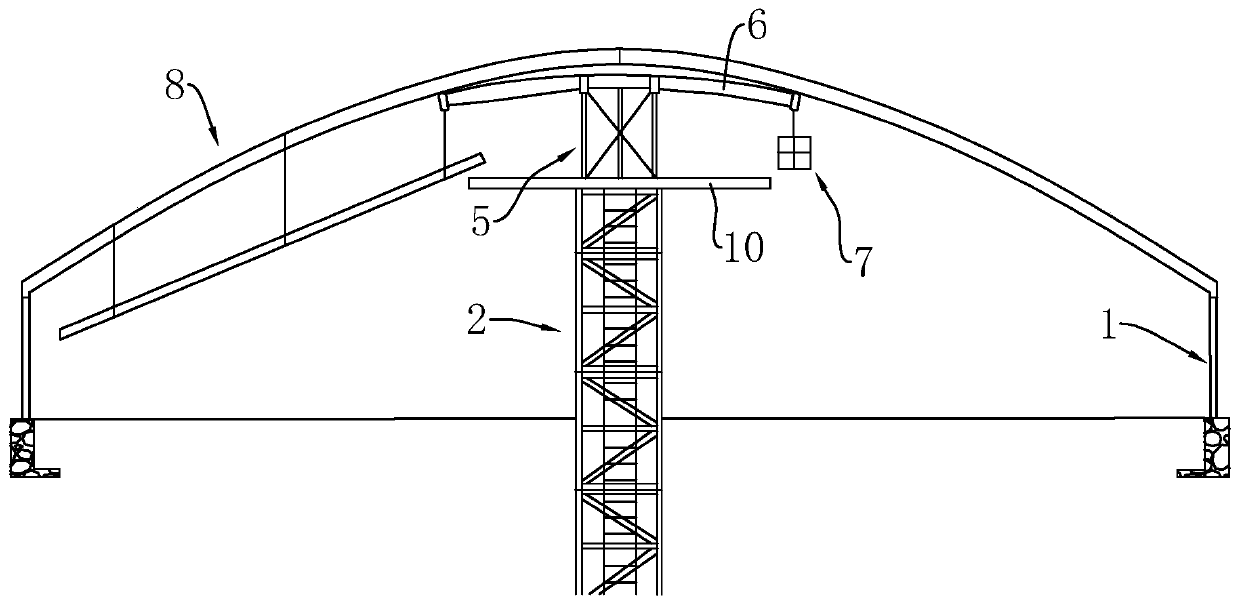

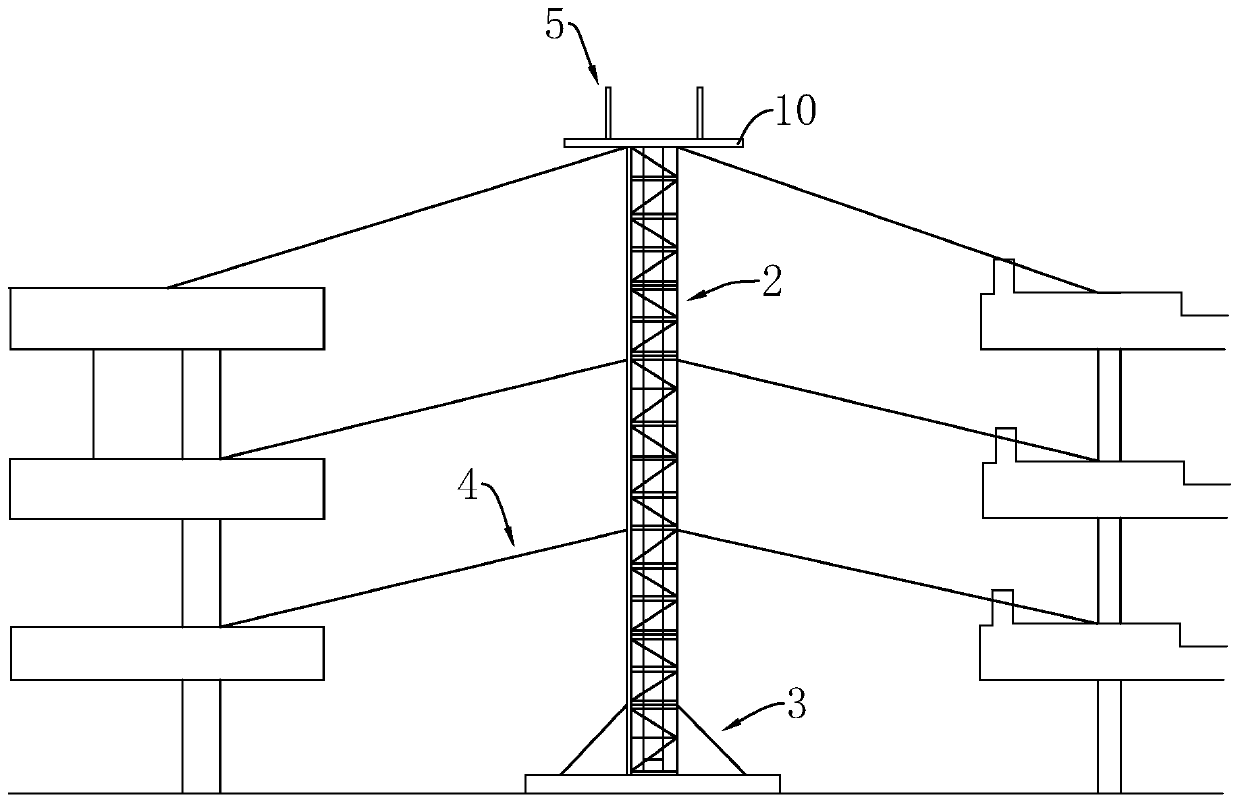

[0051] See attached figure 1And attached figure 2 , a method for installing a daylighting roof steel structure, comprising the following steps:

[0052] S1. Fix a circle of bottom brackets 1 on the wall. In this embodiment, the lighting roof can be a circular or elliptical structure; correspondingly, the bottom bracket 1 can extend along a circular or elliptical track; after the overall installation of the lighting roof is completed, the bottom bracket 1 can The whole plays a supporting role to ensure the stability of the lighting roof.

[0053] S2. Vertically and fixedly erect the installation platform 2 at the position where the ground faces the center of the daylighting roof. In actual construction, the staff can pre-assemble the installation platform 2, and then hoist the installation platform 2 as a whole to the roof of the building by a tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com