Reduced polyamide material and supported nano metal catalyst and preparation method and application thereof

A nano-metal and nano-metal particle technology, applied in the field of nano-metal catalysts, can solve problems such as long reduction time, and achieve the effect of not easy to agglomerate, mild reaction, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The reduced polyamide material of the present invention can be prepared by conventional methods for preparing polymers in the art. The following preparation methods are preferably adopted, specifically including:

[0033] 1) Dissolving the polyacyl chloride and polyaromatic amine in an organic solvent respectively to form solution A and solution B;

[0034] 2) Under stirring conditions, solution A and solution B are mixed and reacted to obtain a suspension;

[0035] 3) Filtering, washing and drying the suspension to obtain the reducing polyamide material.

[0036] According to the present invention, the organic solvents for dissolving the polybasic acid chlorides and polybasic aromatic amines can be the same or different, each being at least one selected from chloroform, n-hexane, cyclohexane and petroleum ether.

[0037] In the present invention, the concentration of solution A and solution B can be routinely selected according to the prior art, as long as the polyac...

Embodiment 1

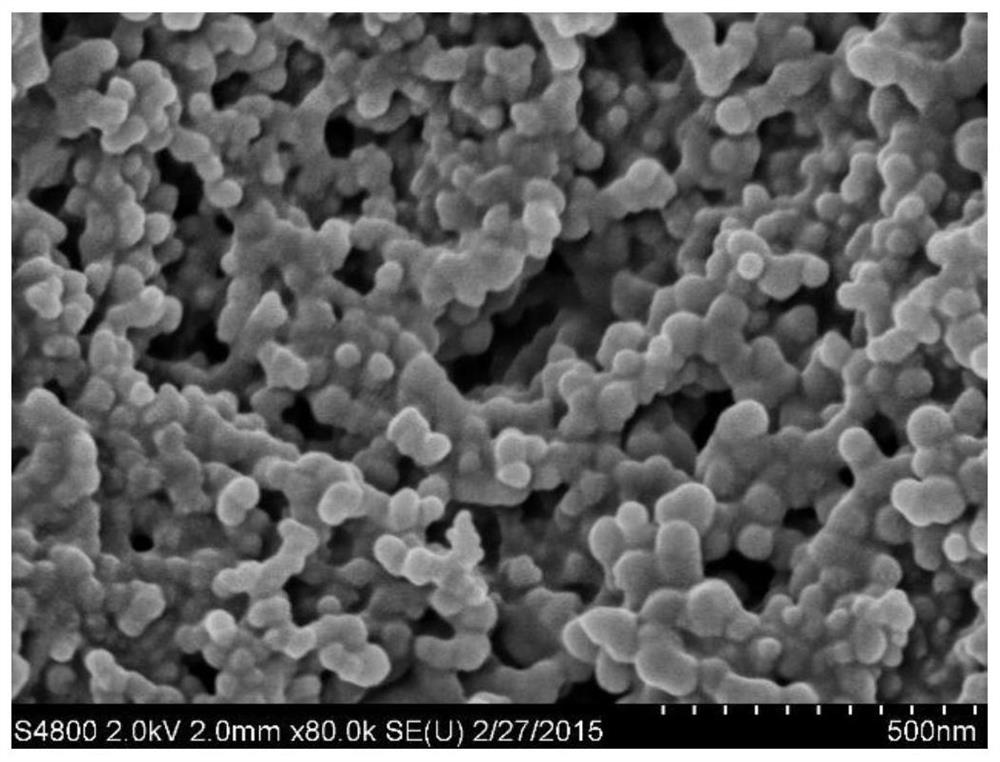

[0061] Weigh 108mg of m-phenylenediamine and dissolve it in chloroform, and another weigh 265mg of trimesoyl chloride and dissolve it in chloroform, add the former solution and stir, and a large amount of white insoluble matter is rapidly formed. After stirring for 10 minutes, the reaction was stopped, and a white suspension was obtained. After filtration, a white solid was obtained. After washing and centrifuging several times with ethanol and water, the white reducing polyamide material powder PA-1 was obtained by vacuum drying. Its appearance was as follows: figure 1 shown.

Embodiment 2

[0063] Weigh 324mg of m-phenylenediamine and dissolve it in n-hexane, and another weigh 265mg of trimesoyl chloride and dissolve it in chloroform, add the former solution and stir, and a large amount of white insoluble matter is rapidly formed. After stirring for 5 minutes, the reaction was stopped, and a white suspension was obtained. After filtration, a white solid was obtained. After washing and centrifuging several times with ethanol and water, the mixture was vacuum-dried to obtain a white reducing polyamide material powder PA-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com