Catalyst for catalytic oxidation elimination of formaldehyde and preparation method thereof

A technology to eliminate formaldehyde and catalyze oxidation, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc. Expensive and other issues, to achieve the effect of improving adsorption performance, improving dispersion, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

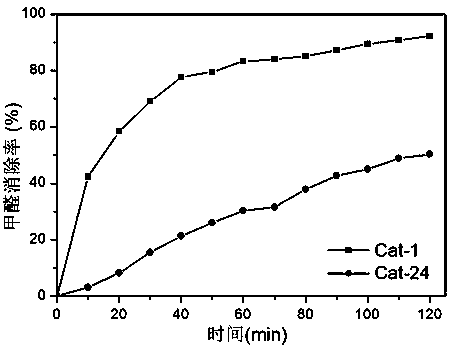

Image

Examples

Embodiment 1

[0025] (1) At room temperature, 0.05 g Na 2 CO 3 Dissolve in 5 g deionized water to get Na 2 CO 3 solution, using the equal volume impregnation method, the Na 2 CO 3 The solution was impregnated in 5 g of activated carbon and dried at 80 °C; then the dried sample was roasted at 400 °C for 4 hours under a hydrogen atmosphere to obtain pretreated activated carbon;

[0026] (2) Dissolve 0.05 g KCl in 5 g deionized water to obtain a KCl solution, then add KOH to adjust the pH value of the solution to 9, and use the equal volume impregnation method to impregnate the above solution into the pretreated activated carbon, at 80 °C After drying, it was roasted at 400°C for 5 hours under a nitrogen atmosphere to obtain sample A;

[0027] (3) Dissolve 0.05 g of cerium nitrate in 5 g of deionized water to obtain a cerium nitrate solution. Under ultrasonic conditions at 40 °C, slowly add 0.01 g of isopropanol to the cerium nitrate solution, and ultrasonically disperse for 1 hour. meth...

Embodiment 2

[0031] The preparation steps of Example 2 are the same as in Example 1, except that KCl in step (2) is replaced by KNO 3 , the obtained catalyst number is Cat-2.

Embodiment 3

[0033] The preparation steps of Example 3 are the same as those of Example 1, except that KCl in step (2) is replaced by K 2 SO 4, the resulting catalyst number is Cat-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com