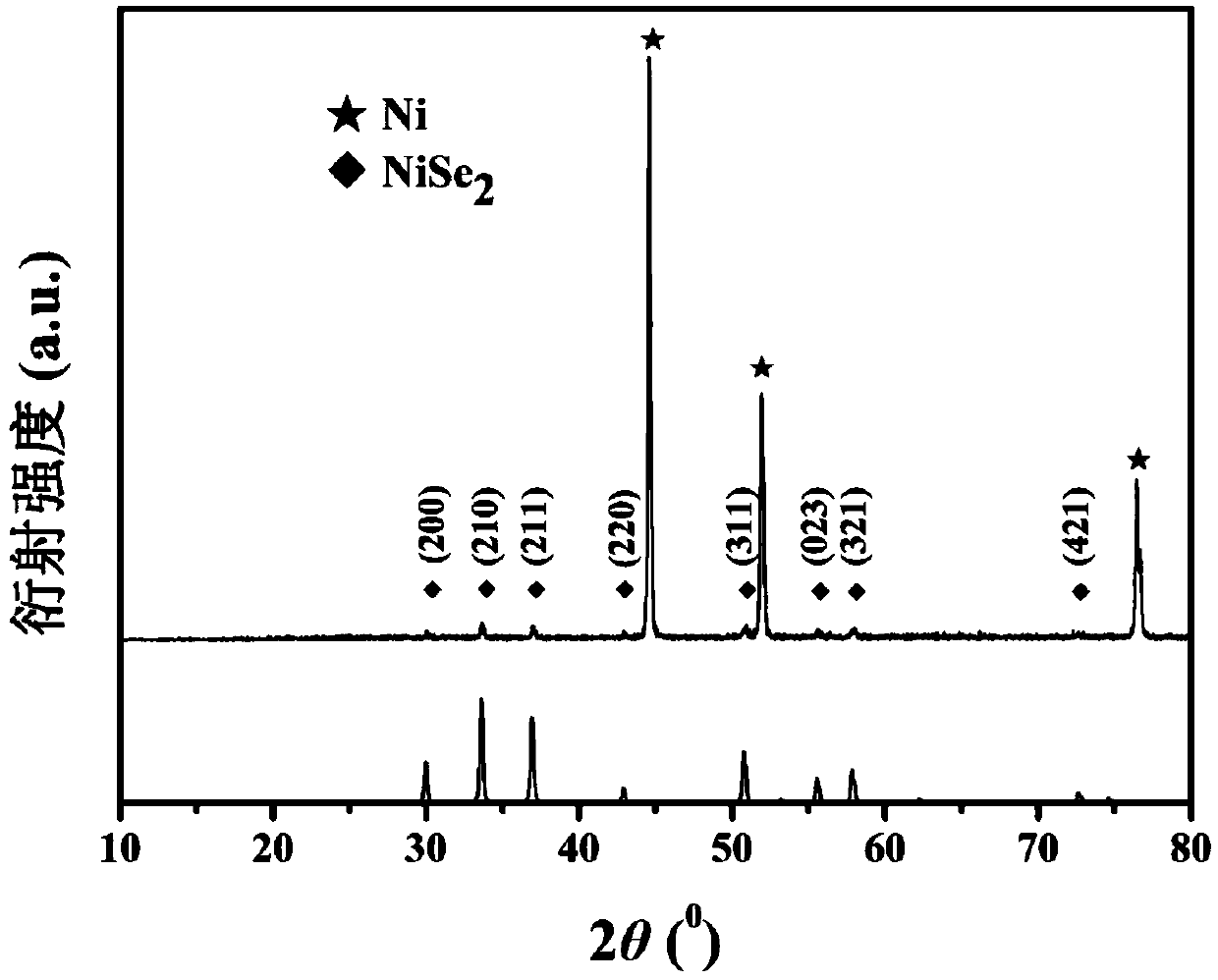

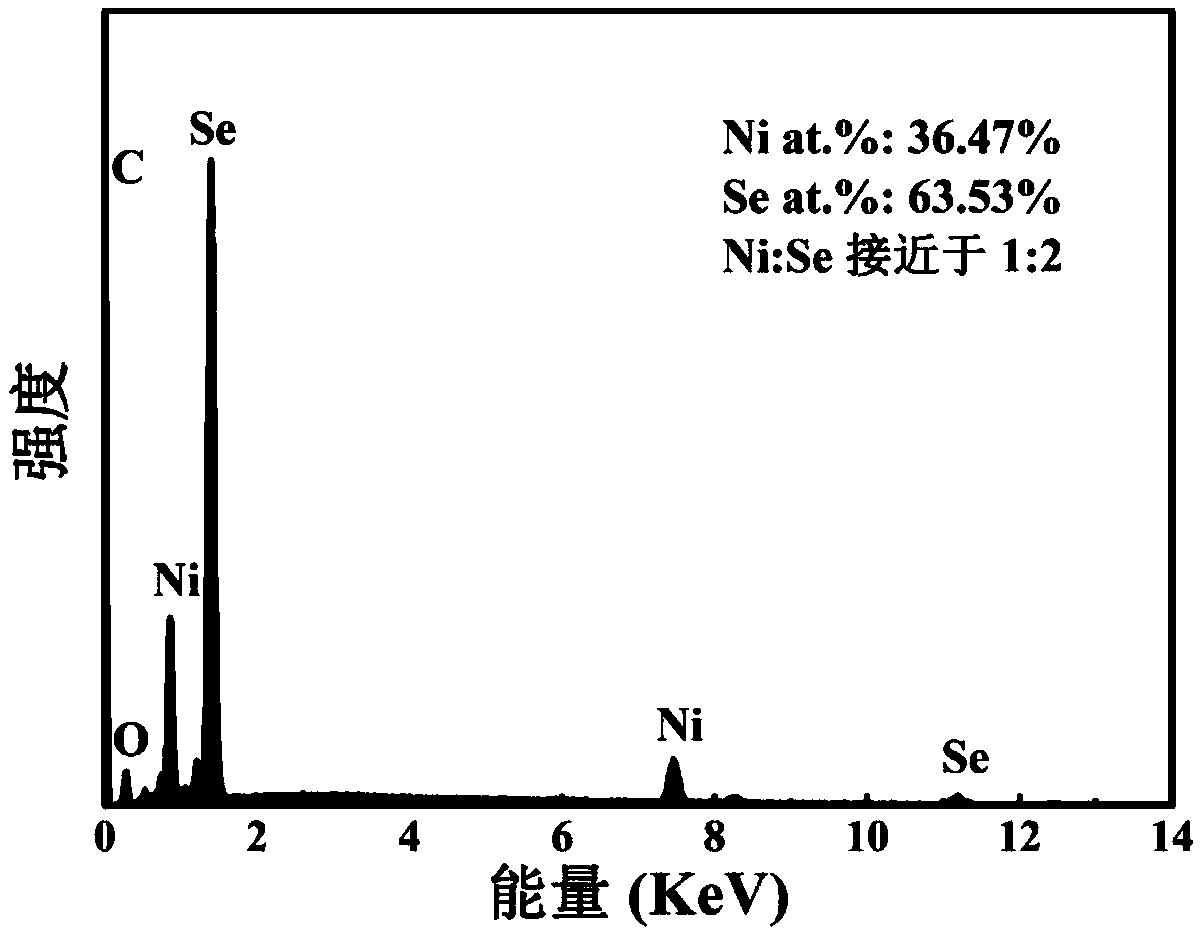

White-beech-mushroom-shaped nickel selenide 2 nano-array electrode material and preparation method thereof

A technology of nickel diselenide and nano-array, which is applied in the direction of nanotechnology, nanotechnology, hybrid capacitor electrodes, etc., can solve the problems of poor conductivity, increased sheet resistance and charge transfer resistance, poor rate performance, etc., to achieve low cost, The effect of cheap raw materials and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] ①Cut commercially available nickel foam into a size of 1×4cm, and ultrasonically treat it with 3mol / L hydrochloric acid for 30 minutes to remove surface oxides. Wash with absolute ethanol and deionized water alternately, and dry in vacuum for later use.

[0024] ② Add 0.10 mmol of Se powder to 18 mL of NaOH solution with a concentration of 0.07 mol / L, and sonicate for 10 min at room temperature. The mixed solution was transferred to a reaction kettle with a volume of 25 mL and lined with p-polyphenylene, and hydrothermally treated at 220° C. for 24 h to obtain a reaction solution with uniform concentration.

[0025] ③ After the reaction solution obtained in step ② is naturally cooled, put the pretreated nickel foam into it, and conduct hydrothermal treatment at 220° C. for 12 hours. After the reaction, the sample was naturally cooled to room temperature, washed with absolute ethanol and deionized water for several times, and then dried in vacuum to obtain the white jad...

Embodiment 2

[0028] ①Cut commercially available nickel foam into a size of 1×4cm, and ultrasonically treat it with 3mol / L hydrochloric acid for 30 minutes to remove surface oxides. Wash with absolute ethanol and deionized water alternately, and dry in vacuum for later use.

[0029] ② Add 0.12 mmol of Se powder to 18 mL of NaOH solution with a concentration of 0.1 mol / L, and sonicate for 10 min at room temperature. The mixed solution was transferred to a reaction kettle with a volume of 25 mL and lined with p-polyphenylene, and hydrothermally treated at 220° C. for 36 h to obtain a reaction solution with uniform concentration.

[0030] ③ After the reaction solution in step ② is naturally cooled, put the pretreated nickel foam into it, and heat it with water at 200°C for 24 hours. After the reaction was naturally cooled to room temperature, the sample was washed several times with absolute ethanol and deionized water, and then vacuum-dried to obtain a white jade mushroom-like nickel diselen...

Embodiment 3

[0033] ①Cut commercially available nickel foam into a size of 1×4cm, and ultrasonically treat it with 3mol / L hydrochloric acid for 30 minutes to remove surface oxides. Wash with absolute ethanol and deionized water alternately, and dry in vacuum for later use.

[0034] ② Add 0.2 mmol of Se powder to 18 mL of NaOH solution with a concentration of 0.12 mol / L, and sonicate for 10 min at room temperature. The mixed solution was transferred to a reaction kettle with a volume of 25 mL and lined with p-polyphenylene, and hydrothermally treated at 220° C. for 24 h to obtain a reaction solution with uniform concentration.

[0035] ③ After the reaction solution in step ② is naturally cooled, put the pretreated nickel foam into it, and conduct hydrothermal treatment at 200° C. for 16 hours. After the reaction was naturally cooled to room temperature, the sample was washed several times with absolute ethanol and deionized water, and then vacuum-dried to obtain a white jade mushroom-like ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com