Method for displaying high-strength steel grain size

A grain-size, high-strength steel technology for particle size analysis, sample preparation for testing, particle and sedimentation analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

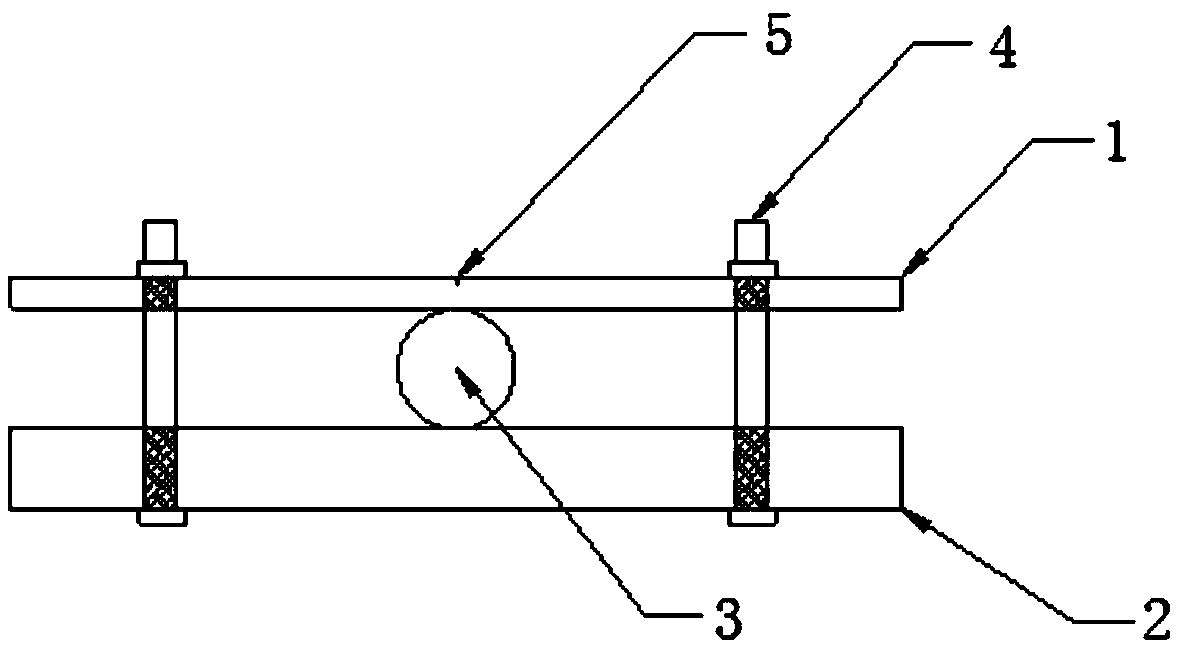

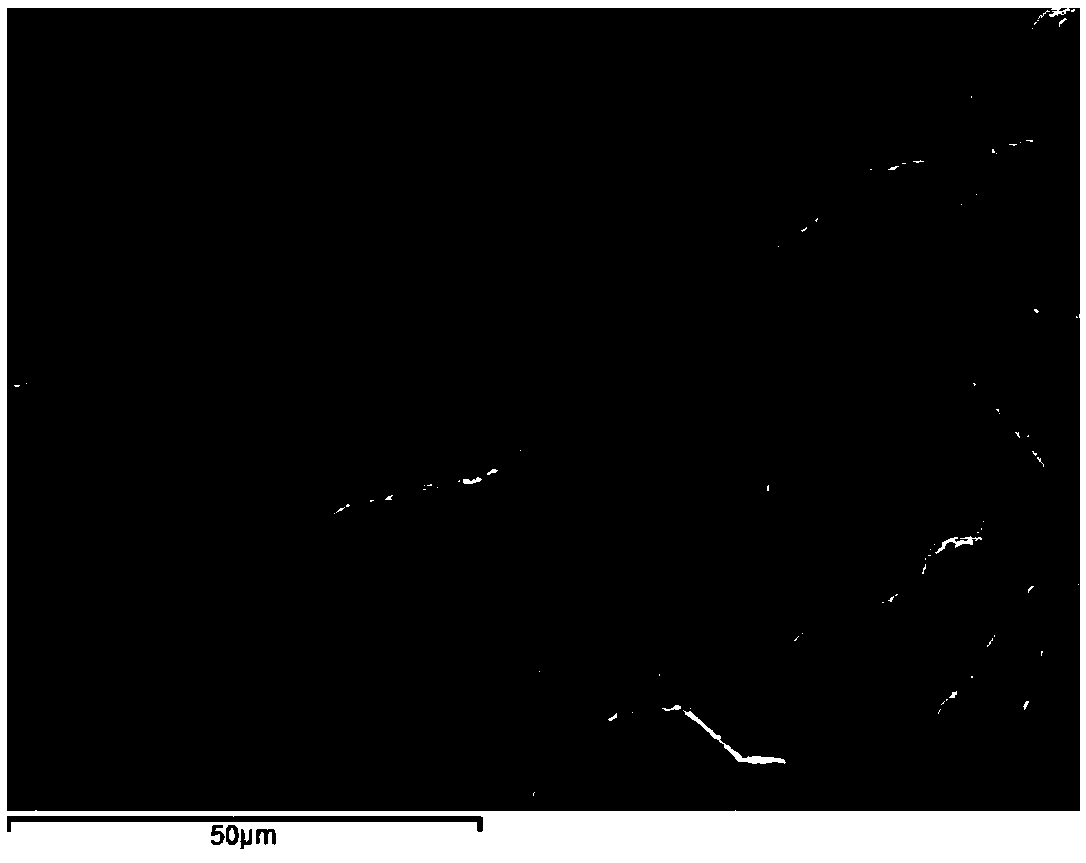

[0026] First process the high-strength steel wire into two beams with a thickness of 3mm, a length of 146mm, and a width of 11mm. In the middle of each beam and along the thickness direction, use a CNC cutting machine to open a slot whose length is 20% of the thickness of the beam. The slot The width is 1mm, and then drill a hole with a diameter of 8mm at a distance of 12.5mm from both ends. Use the same high-strength steel wire to make two distance bolts with a diameter of 14mm and a height of 11mm and prepare two hexagonal screws. Measure 0.16mL of concentrated sulfuric acid of analytical grade, pour it into 999.84mL of distilled water and stir evenly, weigh 0.4g of sodium phosphate and add it to the sulfuric acid solution, and stir evenly until completely dissolved. Put the sides of the two beams with the slots facing outwards, and screw them slightly through the holes with the hexagonal screws, then place the two distance bolts between the two beams, the distance between th...

Embodiment 2

[0028] First process the high-strength steel wire into two beams with a thickness of 2mm, a length of 146mm, and a width of 11mm. In the middle of each beam and along the thickness direction, use a CNC cutting machine to open a slot whose length is 20% of the thickness of the beam. The slot The width is 1mm, and then drill a hole with a diameter of 8mm at a distance of 12.5mm from both ends. Use the same high-strength steel wire to make two distance bolts with a diameter of 14mm and a height of 11mm and prepare two hexagonal screws. Measure 0.53mL of concentrated sulfuric acid of analytical grade, pour it into 999.47mL of distilled water and stir evenly, weigh 0.4g of sodium phosphate into the sulfuric acid solution, and stir evenly until completely dissolved. Put the sides of the two beams with the slots facing outwards, and screw them slightly through the holes with the hexagonal screws, then place the two distance bolts between the two beams, the distance between the centers...

Embodiment 3

[0030] First process the high-strength steel wire into two beams with a thickness of 2mm, a length of 146mm, and a width of 11mm. In the middle of each beam and along the thickness direction, use a CNC cutting machine to open a slot whose length is 20% of the thickness of the beam. The slot The width is 1mm, and then drill a hole with a diameter of 8mm at a distance of 12.5mm from both ends. Use the same high-strength steel wire to make two distance bolts with a diameter of 14mm and a height of 11mm and prepare two hexagonal screws. Measure 0.16mL of concentrated sulfuric acid of analytical grade, pour it into 999.84mL of distilled water and stir evenly, weigh 0.4g of sodium phosphate and add it to the sulfuric acid solution, and stir evenly until completely dissolved. Put the sides of the two beams with the slots facing outwards, and screw them slightly through the holes with the hexagonal screws, then place the two distance bolts between the two beams, the distance between th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com