Biological extraction method for fibers in phloem raw materials in waste crops

A technology of biological extraction and crops, which is applied in the field of resource utilization of discarded crops, can solve problems such as difficult strains, and achieve the effects of improving economic benefits, broad application prospects, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of biological extraction method of pineapple leaf of embodiment 1

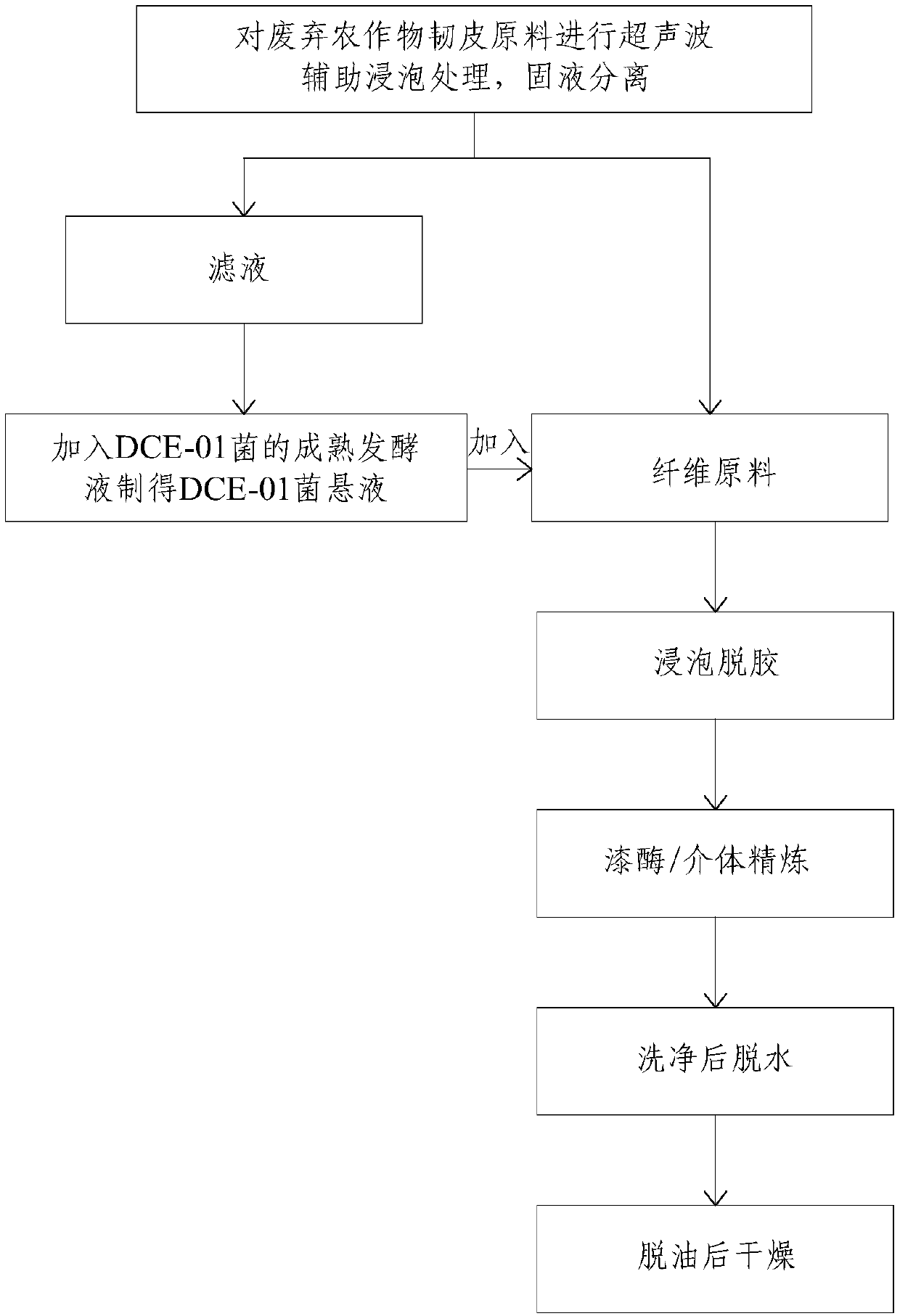

[0032] Such as figure 1 As shown, soak the dried pineapple leaf fiber raw material prepared by mechanical scraping with tap water, the bath ratio is 1: 15-20, and the time is 20 minutes. Ultrasonic treatment was performed for 20 minutes under the condition of power of 200W and frequency of 80kHz, the solid and liquid were separated, and the ultrasonic filtrate and fiber raw materials were collected separately for future use.

[0033] Pick a ring of DCE-01 strains from the original slant lawn preserved by the project team to inoculate 5.0mL of improved broth culture solution, suspend well, and incubate at 34°C for 5.5h. Spread on nutrient agar plate after dilution, incubate at 34°C for 18 hours, and isolate a single colony. Select typical colonies and inoculate them into 5.0 mL of improved broth culture solution, and incubate at 34°C for 5 hours, which is the primary seed solution. Inoculate th...

Embodiment 2

[0036] Embodiment 2 A kind of biological extraction method of banana bast fiber

[0037] Soak the dry banana bast fiber raw material scraped by machinery with tap water, the bath ratio is 1:20, and the time is 25min. After treatment with ultrasonic wave for 30 minutes under the condition of power of 200W and frequency of 80kHz, the solid and liquid were separated, and the ultrasonic filtrate and banana bast fiber raw material were collected respectively for future use.

[0038]Pick a ring of DCE-01 strains from the original slant lawn preserved by the project team to inoculate 5.0mL of improved broth culture solution, suspend well, and incubate at 34°C for 5.5h. Spread on nutrient agar plate after dilution, incubate at 34°C for 18 hours, and isolate a single colony. Select typical colonies and inoculate them into 5.0 mL of improved broth culture solution, and incubate at 34°C for 5 hours to obtain the primary seed solution. Inoculate the test tube solution into a 100mL Erlen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com