Flame-retardant silicone rubber and continuous production technology and system thereof

A production process, silicone rubber technology, applied in the field of silicone rubber, can solve the problem of reducing the tensile strength of silicone rubber products, elongation at break, tear strength and other mechanical strength and processing formability, which cannot meet the performance requirements of silicone rubber, It is prone to problems such as dripping, so as to improve the processing formability and stability, improve plasticity, and prevent smoking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

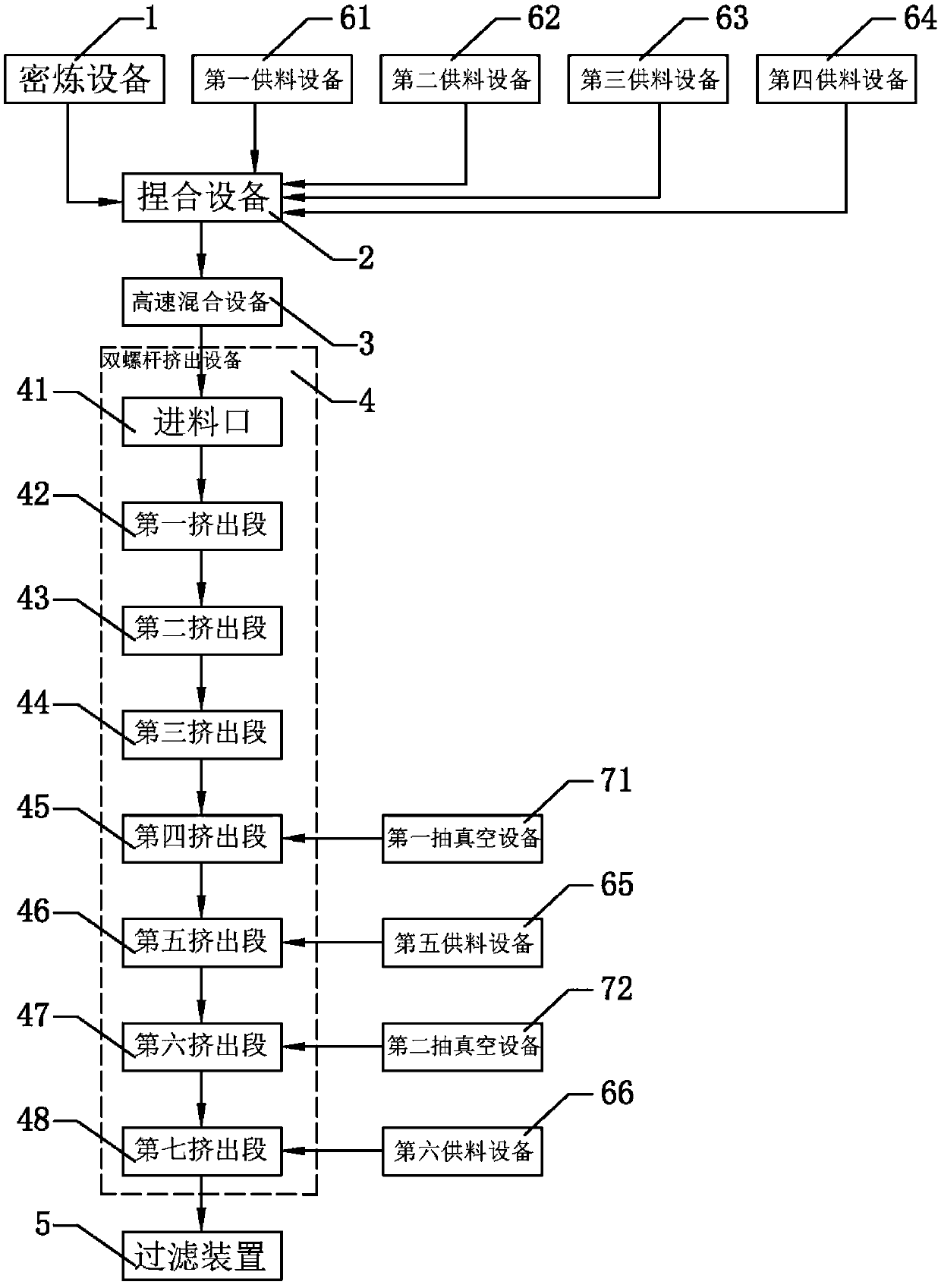

Method used

Image

Examples

Embodiment 1

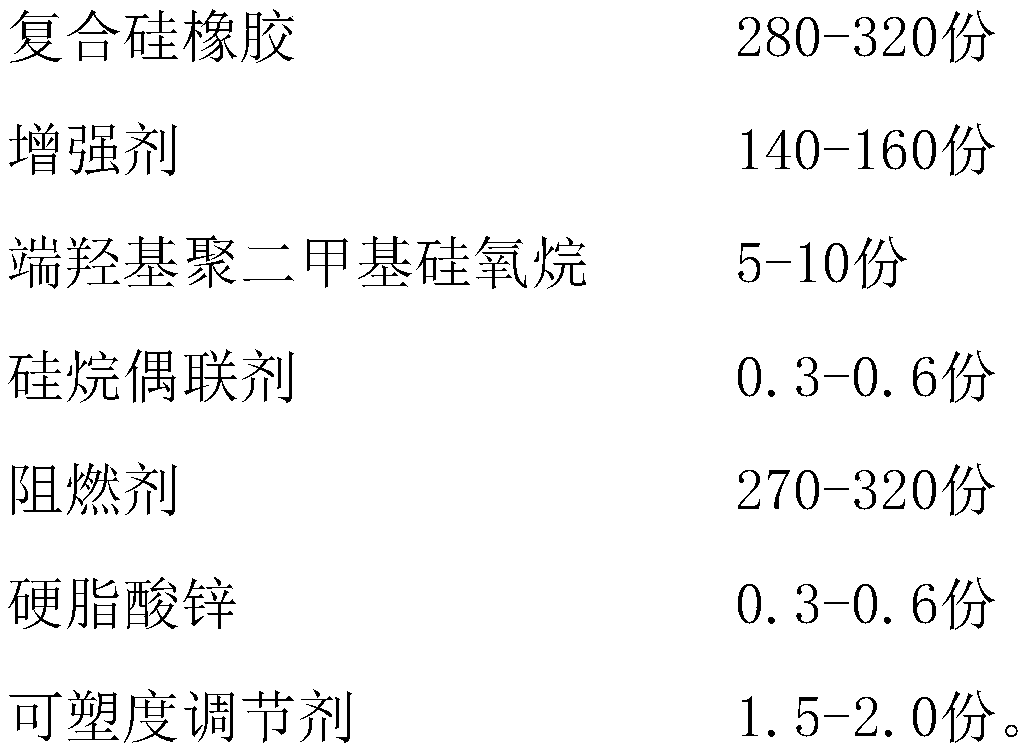

[0046] A flame-retardant silicone rubber, comprising the following raw materials in parts by weight:

[0047]

[0048] The composite silicone rubber is a mixture of methyl vinyl silicone rubber A and methyl vinyl silicone rubber B in a weight ratio of 1:0.8; wherein, the vinyl content of the methyl vinyl silicone rubber A is 0.04 %, the methyl content is 99.96%, and the molecular weight is 550,000; the vinyl content of the methyl vinyl silicone rubber B is 0.14%, the methyl content is 99.86%, and the molecular weight is 550,000.

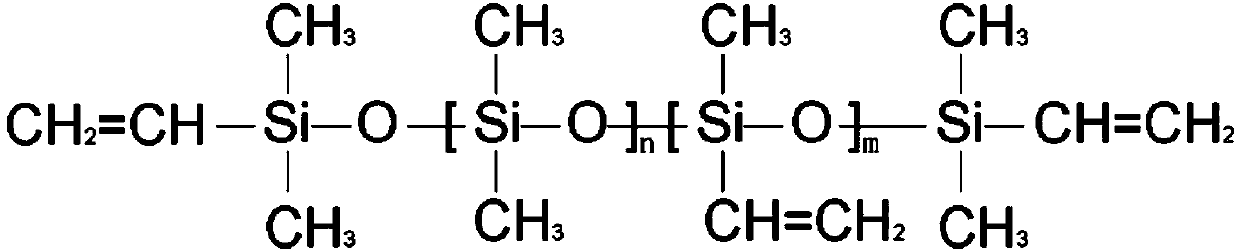

[0049] The chemical formulas of the above-mentioned methyl vinyl silicone rubber A and methyl vinyl silicone rubber B are as follows:

[0050]

[0051] Wherein, n=8780, m=3 of the methyl vinyl silicone rubber A; n=8150, m=10 of the methyl vinyl silicone rubber B.

[0052] The reinforcing agent has a specific surface area of 200m 2 / g of precipitated white carbon black; the silane coupling agent is propyltrimethoxysilane.

[0053] The flame...

Embodiment 2

[0063] A flame-retardant silicone rubber, comprising the following raw materials in parts by weight:

[0064]

[0065]

[0066] The composite silicone rubber is a mixture of methyl vinyl silicone rubber A and methyl vinyl silicone rubber B in a weight ratio of 1:1; wherein, the vinyl content of the methyl vinyl silicone rubber A is 0.08 %, the methyl content is 99.82%, and the molecular weight is 600,000; the vinyl content of the methyl vinyl silicone rubber B is 0.16%, the methyl content is 99.84%, and the molecular weight is 600,000.

[0067] The chemical formulas of the above-mentioned methyl vinyl silicone rubber A and methyl vinyl silicone rubber B are as follows:

[0068]

[0069] Wherein, n=8750, m=7 of the methyl vinyl silicone rubber A; n=8100, m=13 of the methyl vinyl silicone rubber B.

[0070] The reinforcing agent has a specific surface area of 250m 2 / g of precipitated white carbon black; the silane coupling agent is vinyltrimethoxysilane.

[0071] ...

Embodiment 3

[0081] A flame-retardant silicone rubber, comprising the following raw materials in parts by weight:

[0082]

[0083] The composite silicone rubber is a mixture of methyl vinyl silicone rubber A and methyl vinyl silicone rubber B in a weight ratio of 1:1.2; wherein, the vinyl content of the methyl vinyl silicone rubber A is 0.12 %, the methyl content is 99.88%, and the molecular weight is 650,000; the vinyl content of the methyl vinyl silicone rubber B is 0.18%, the methyl content is 99.82%, and the molecular weight is 650,000.

[0084] The chemical formulas of the above-mentioned methyl vinyl silicone rubber A and methyl vinyl silicone rubber B are as follows:

[0085]

[0086] Wherein, n=8730, m=10 of the methyl vinyl silicone rubber A; n=8050, m=15 of the methyl vinyl silicone rubber B.

[0087] The reinforcing agent has a specific surface area of 300m 2 / g of precipitated white carbon black; the silane coupling agent is vinyltriethoxysilane.

[0088] The flame ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com