Method for preparing organic fertilizer from cephalosporin fungus residues

A cephalosporin and organic fertilizer technology, applied in the directions of organic fertilizers, inorganic fertilizers, urea compound fertilizers, etc., can solve the problems of low production efficiency and poor product quality, reduce costs and work efficiency, reduce strength and cost, and meet the The effect of fertilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

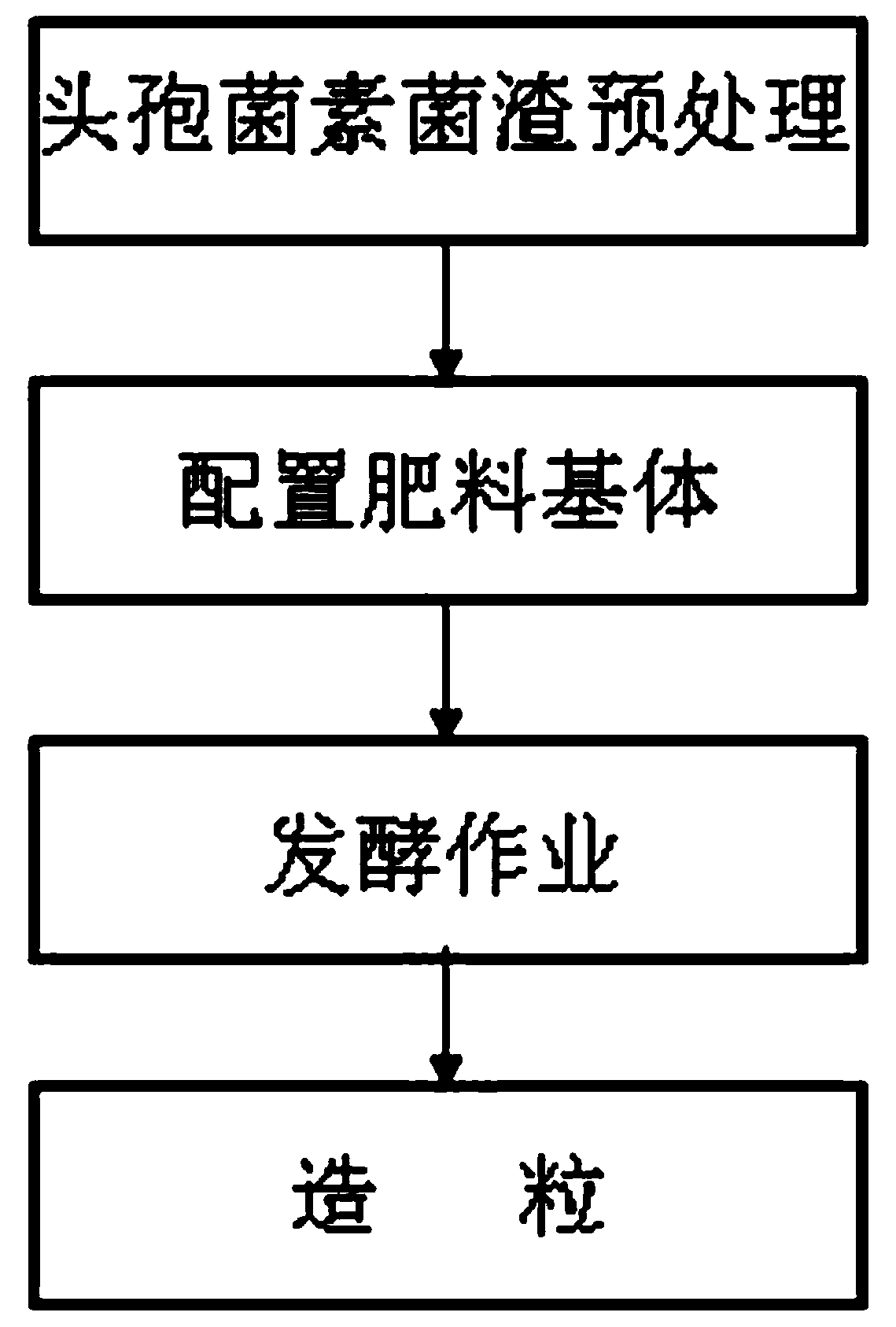

[0023] Such as figure 1 Shown, a kind of cephalosporin slag prepares the method for organic fertilizer, comprises the steps:

[0024] The first step, cephalosporin residue pretreatment, first freeze-dry the fresh cephalosporin residue in a cold air environment with an air velocity of 3.5m / s at -10°C, and freeze the fresh cephalosporin residue into block, and then break the frozen cephalosporin slag into solid particles with a particle size of 5-20 mm, and then pass the cephalosporin slag solid particles into a heating furnace with an oxygen content of 0, and in 5 minutes Internally raise the temperature of the solid cephalosporin residue to 800°C and keep it warm for 30 minutes, then naturally cool down to 40°C with the furnace to obtain the pretreated cephalosporin residue and keep it warm for later use;

[0025] The second step is to configure the fertilizer matrix. First, dry the selected volcanic rock materials, pyrite slag, activated carbon particles, rare earth, calcium...

Embodiment 2

[0036] Such as figure 1 Shown, a kind of cephalosporin slag prepares the method for organic fertilizer, comprises the steps:

[0037] The first step, cephalosporin residue pretreatment, first freeze-dry the fresh cephalosporin residue in a cold air environment with an air velocity of 0.5m / s at -5°C, and freeze the fresh cephalosporin residue into block, and then break the frozen cephalosporin slag into solid particles with a particle size of 20mm, and then pass the cephalosporin slag solid particles into a heating furnace with an oxygen content of 15%, and within 10 minutes Heating the solid cephalosporin residue to 1200°C and keeping it warm for 30 minutes, then cooling down to 50°C naturally with the furnace to obtain the pretreated cephalosporin residue and keeping it warm for later use;

[0038] The second step is to configure the fertilizer matrix. First, dry the selected volcanic rock materials, pyrite slag, activated carbon particles, rare earth, calcium sulfate, borax...

Embodiment 3

[0049] Such as figure 1 Shown, a kind of cephalosporin slag prepares the method for organic fertilizer, comprises the steps:

[0050] The first step, cephalosporin residue pretreatment, first freeze-dry the fresh cephalosporin residue in a cold air environment with an air velocity of 1.5m / s at -8°C, and freeze the fresh cephalosporin residue into block, then crush the frozen cephalosporin slag into solid particles with a particle size of 15mm, and then pass the cephalosporin slag solid particles into a heating furnace with an oxygen content of 8%, and within 7 minutes Heating the solid cephalosporin residue to 1000°C and keeping it warm for 20 minutes, then naturally cooling to 45°C with the furnace to obtain the pretreated cephalosporin residue and keeping it warm for later use;

[0051] The second step is to configure the fertilizer matrix. First, dry the selected volcanic rock material, pyrite slag, activated carbon particles, rare earth, calcium sulfate, borax and organic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com